Valves play a crucial role in marine and offshore operations, controlling the flow of liquids and gases in pipelines throughout ships and offshore platforms. Without reliable marine valves, systems can fail, leading to downtime, costly repairs, or even safety hazards. For procurement teams and marine engineers, understanding the right type of valve and its application is essential. This guide will cover valve types, materials, standards, and maintenance tips to help buyers make informed decisions.

1.Harsh Marine Environments and Valve Challenges

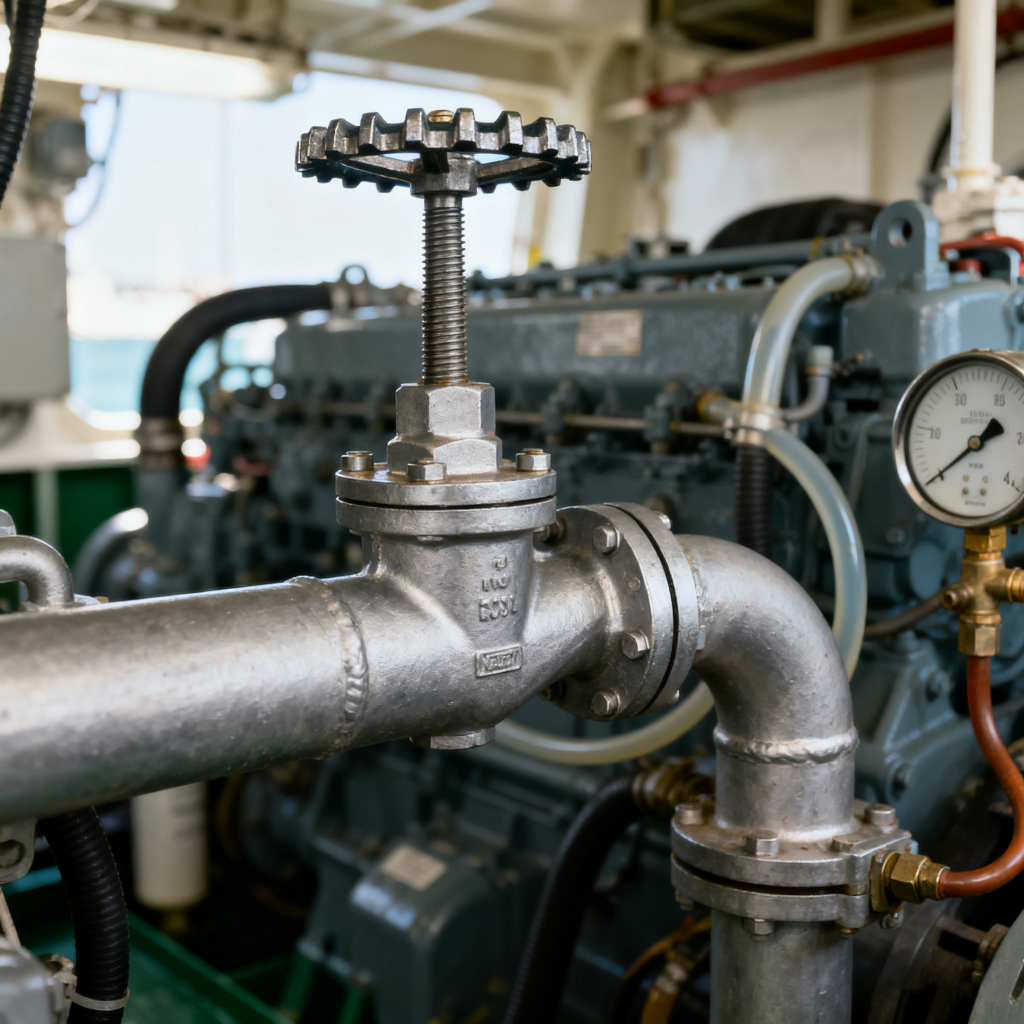

Marine and offshore environments are extremely harsh. Saltwater, high pressure, extreme temperatures, and constant vibration can quickly wear down poorly designed valves. Choosing corrosion-resistant marine valves and high-quality marine machinery is crucial for long-term reliability. For procurement teams, knowing these challenges helps select valves that can withstand tough conditions.

2.Key Valve Functions

Valves control liquids and gases, prevent backflow, and regulate system pressure to ensure safe operation. Choosing the right marine valves helps marine engineers maintain efficiency and avoid costly downtime. Understanding these functions is a critical step for buyers in the marine industry.

3.Essential Features

High-quality marine valves must withstand harsh offshore conditions. Corrosion and saltwater resistance are critical, with stainless steel or high-grade alloys preventing deterioration. Valves must tolerate high pressure, extreme temperatures, and vibration. Focusing on these features reduces maintenance costs and prevents downtime. Procurement teams should evaluate material, design, and sealing mechanisms to ensure compliance with safety standards.

4.Valve Types

Common marine valves include:

- Gate Valves: Reliable on/off control for large pipelines.

- Ball Valves: Quick shut-off for emergencies.

- Butterfly Valves: Compact, cost-effective, ideal for tight spaces.

- Globe Valves: Precise flow regulation for fuel and chemical lines.

- Check Valves: Prevent backflow, protecting pumps and equipment.

- Relief/Safety Valves: Protect systems from overpressure.

Assess each type based on application, pressure, and installation space. Understanding these categories helps buyers select the right valve for efficiency and safety.

5.Material Selection

Choosing the right material is one of the most important steps when selecting marine valves, as it directly affects durability, maintenance needs, and long-term costs. Common options include:

- Stainless Steel Marine Valves: The most popular choice for ships and offshore systems because they combine strength with excellent resistance to saltwater corrosion.

- Duplex Stainless Steel: A stronger grade that provides even greater durability and longer service life in aggressive marine conditions, making it ideal for offshore platforms and heavy-duty systems.

- Bronze and Brass Valves: Affordable and reliable, these materials are often used in older vessels and smaller pipelines where pressure is lower but consistent performance is still required.

- High-Alloy Materials for LNG and Drilling: Chosen for specialized applications such as LNG carriers or offshore drilling rigs, where valves must withstand extreme pressure and freezing temperatures without losing performance.

- Cost vs Durability Balance: Buyers and procurement teams should always weigh initial price against long-term reliability, since choosing the wrong material can lead to higher maintenance costs and unexpected downtime.

6.Standards and Certifications

Compliance ensures marine valves meet safety and performance requirements:

- IMO and SOLAS: Mandatory maritime safety regulations.

- API, ABS, DNV: Globally recognized certifications.

Selecting certified valves reduces risk, ensures compliance, and improves operational reliability.

7.Installation and Maintenance

Proper installation and regular maintenance are critical. Space constraints require careful planning for accessibility. Routine inspection, wear monitoring, lubrication, and cleaning extend valve life. Buyers and procurement teams should understand installation requirements and maintenance schedules to ensure reliable operation with other marine machinery.

8.Valve Actuation Options

Actuation methods for marine valves include:

- Manual: Simple, reliable, easy to maintain.

- Pneumatic/Hydraulic: Remote operation and partial automation.

- Electric/Smart: Full automation, real-time monitoring, and system integration.

Choosing the right method ensures efficiency, safety, and compatibility.

9.Cost and Procurement Tips

When selecting marine valves, balance cost and quality. Working with certified suppliers prevents substandard purchases. Understanding long-term maintenance, vendor support, and spare parts availability helps buyers and procurement teams make cost-effective decisions.

10.Emerging Valve Trends

Smart marine valves with digital monitoring reduce failures and downtime. Eco-friendly designs minimize environmental impact. Staying updated ensures investments improve efficiency, safety, and sustainability across ships and offshore platforms.

Conclusion

Selecting the right marine valves is crucial for safety, efficiency, and longevity. By considering types, materials, standards, actuation, and maintenance, buyers and procurement teams can make informed decisions. High-quality, certified valves ensure reliable performance, reduce downtime, and support sustainable marine operations.