WANVALVE Electric Wafer Butterfly Valve Stainless Steel WE20-W-S

The WANVALVE WE20-W-S Electric Wafer Butterfly Valve Stainless Steel is a precision-engineered flow control device designed for reliable automation in modern industrial systems. Constructed from high-quality austenitic and duplex stainless steel grades, this electric butterfly valve with wafer-style design delivers accurate fluid control across a wide range of media, including water, chemicals, air, and light slurry. Its robust design ensures dependable performance, even under high temperatures and challenging industrial conditions. Whether used in process pipelines, HVAC systems, or industrial automation, the WE20-W-S provides long-lasting reliability and precise valve positioning.

Superior Stainless Steel Construction

The wafer butterfly valve body is available in various types of high-quality steel, including SS304, SS316, SS316L, martensitic stainless steel, and ferritic stainless steels. These materials provide excellent mechanical properties, high resistance to corrosion, and durability under extreme operating conditions. A smooth surface finish and cleanable design make it ideal for applications requiring hygienic or easy to clean components. For chemical or high-temperature applications, the corrosion resistance is enhanced by a passive chromium oxide layer naturally formed on the stainless steel surface. Optional WCB carbon steel body is also available for specific industrial requirements.

The seat and sealing components are crafted from PTFE or EPDM, ensuring tight shutoff and long service life, while reducing maintenance costs. These materials are particularly resistant to chemical attack, temperature variations, and wear.

Electric Actuation for Automation

Equipped with a high-torque electric actuator, the WE20-W-S provides smooth and precise control with rapid response times. This motorized valve system supports both on/off and modulating operation, allowing seamless integration into automated processes. Its quarter-turn design enables fast valve operation and accurate valve positioning, ensuring consistent flow control even under fluctuating pressures. By replacing manual operation with electric actuated control, users gain enhanced safety, efficiency, and reliability.

For more insights on electric actuated systems, see controleng.com for industry guidance.

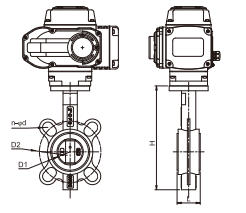

Wafer-Style Design for Easy Installation

The wafer-style body allows easy installation between flanges according to international standards including ANSI, JIS, DIN, and GB. This compact design reduces installation space and simplifies maintenance. Alignment holes ensure quick centering, while the short face-to-face dimension saves both time and costs. A lug style option is also available for systems requiring independent flange removal.

Technical Specifications

| Specification | Details |

|---|---|

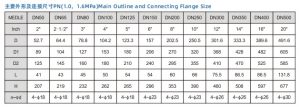

| Size Range | DN50 to DN200 (2”–24”) |

| Pressure Rating | 16 bar (232 psi) |

| Temperature Range | -5°C to 180°C (23°F to 356°F) |

| Connection Type | Wafer (ANSI/JIS/DIN/GB) |

| Body Materials | SS304 / SS316 / SS316L (Optional WCB) |

| Seat Materials | PTFE / EPDM |

| Operation | Electric Actuated (On/Off or Modulating) |

Key Features & Benefits

-

Compact wafer butterfly design for space-saving installation

-

Electric actuator ensures precise flow control and valve positioning

-

Durable stainless steel body resistant to corrosion

-

Compatible with multiple grades of high-quality steel and international flange standards

-

PTFE/EPDM seals offer chemical resistance and leak-free performance

-

High-temperature tolerance and long service life reduce operational costs

-

Hygienic and easy to clean design suitable for diverse industries

Typical Applications

The WANVALVE electric actuated butterfly valve in wafer style is ideal for various industries:

-

Water and wastewater treatment systems (wef.org)

-

Chemical and petrochemical processing

-

Food and beverage production (sourcifychina.com)

-

HVAC and energy management systems (belimo.us)

-

Marine, pharmaceutical, and general industrial automation

Its reliability, precise actuation, and robust construction make it a trusted choice wherever efficient and automated flow control is required.

Conclusion

With a durable stainless steel body, electric actuated operation, and versatile wafer connection, the WANVALVE WE20-W-S delivers superior performance and longevity. Designed for demanding industrial environments, it ensures smooth operation, minimal downtime, and optimal control efficiency. Ideal for both new installations and system upgrades, this actuated valve is the perfect solution for achieving automated, high-performance flow control in industrial applications.