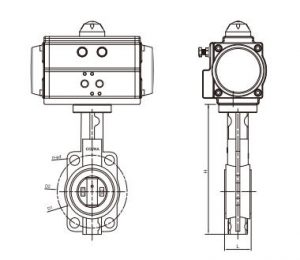

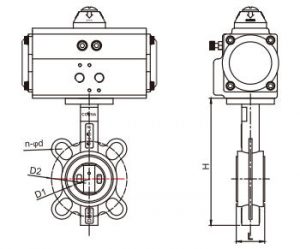

WANVALVE Cast Iron Pneumatic Wafer Butterfly Valve WP12-W

The WANVALVE WP12-W pneumatic wafer butterfly valve is a high-performance style valve designed to precisely control the flow of liquids, gases, and semi-corrosive media.

Its compact wafer style valve body allows easy installation between flanges while maintaining tight sealing and low pressure drops, making it ideal for industrial flow control systems.

Durable Structure and Corrosion Resistance

Built with a stainless steel disc and PTFE or EPDM sealing, the WP12-W ensures excellent corrosion resistance and long service life.

Its quarter-turn pneumatic actuator provides rapid and reliable automation, making it one of the most dependable actuated butterfly valves in demanding industrial environments.

Technical Specifications

| Parameter | Specification |

|---|---|

| Model | WP12-W |

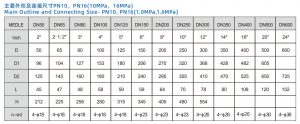

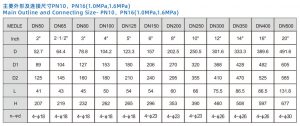

| Size Range | DN50 to DN600 (2”–24”) |

| Pressure Rating | 10–16 bar (145–232 psi) |

| Temperature Range | -5°C to 180°C (23°F to 356°F) |

| Connection Type | Wafer (ANSI / JIS / DIN / GB) |

| Valve Body Material | Cast Iron / Ductile Iron |

| Disc Material | Stainless Steel / Cast Iron |

| Sealing Material | PTFE / EPDM |

| Actuation Type | Single Acting or Double Acting Pneumatic Actuator |

-

For small-diameter valves or valves with pressure requirements, in order to enhance the stability and sealing of the valve disc:

-

For large-diameter valves or valves that are operated frequently, in order to reduce friction and wear:

Highlights of Wafer, Pneumatic, and Cast Iron Design

The WP12-W butterfly valve stands out for its combination of structural innovation and durable materials:

-

Wafer Design:

The wafer-style configuration minimizes space requirements and simplifies installation between flanges. It provides excellent alignment and reduces the risk of leakage compared to lug style valves. -

Pneumatic Actuation:

The integrated pneumatic actuator ensures fast, precise, and automated quarter-turn operation. It enhances system efficiency, reduces manual intervention, and delivers consistent performance under varying high pressure conditions.

For a detailed explanation of how a pneumatic butterfly valve operates and its advantages in industrial automation, explore our in-depth guide. -

Cast Iron Construction:

The valve body is made of cast iron or ductile iron, providing robust mechanical strength and superior corrosion resistance. This material choice extends service life while maintaining cost-effectiveness for industrial users.

These design features make the WP12-W an optimal solution for water treatment, HVAC, and chemical systems requiring stable and efficient flow control.

Applications and Advantages

The pneumatic wafer butterfly valve is widely used in industrial automation, wastewater systems, and HVAC pipelines.

Its wafer style design reduces installation space, while the ductile iron valve body ensures resilience under high pressure. Compared to lug style valves, it offers easier maintenance, lower cost, and enhanced operational safety.

Reliable Flow Control Performance

This high-performance butterfly valve uses a quarter-turn mechanism for smooth, precise operation, ensuring minimal pressure drops and superior flow efficiency.

Its advanced sealing technology prevents internal leakage even in corrosive environments.

For more engineering insights and flow control resources, visit runsom.com or worddisk.com.

Operation and Maintenance

The WP12-W pneumatic wafer butterfly valve is designed for easy operation and minimal maintenance. Its compact actuator allows quick replacement of components, while the self-lubricating seat and corrosion-resistant disc reduce wear over time. Routine inspection and periodic actuator calibration ensure long-term accuracy and safety. The valve’s modular structure enables convenient disassembly without removing the entire pipeline, minimizing downtime in industrial operations.

Quality Standards and Selection Guide

Each WP12-W butterfly valve is manufactured under strict quality control and tested according to ISO 5211 and EN 12266 standards. When selecting the correct model, consider factors such as working pressure, media compatibility, and actuator type (single or double acting). WANVALVE provides technical support to ensure the valve matches your specific automation or manual control system, helping you achieve reliable and efficient flow performance.

Conclusion

The WANVALVE WP12-W Pneumatic Wafer Cast Iron Butterfly Valve is a comprehensive solution for modern fluid systems that demand durability, precision, and automation.

Its wafer-style body, pneumatic actuator, and cast iron construction work together to deliver long-lasting reliability and cost efficiency.

Whether installed in high-pressure pipelines or automated control systems, the WP12-W provides seamless integration, low maintenance, and consistent performance — a true representation of WANVALVE’s commitment to quality and high performance.