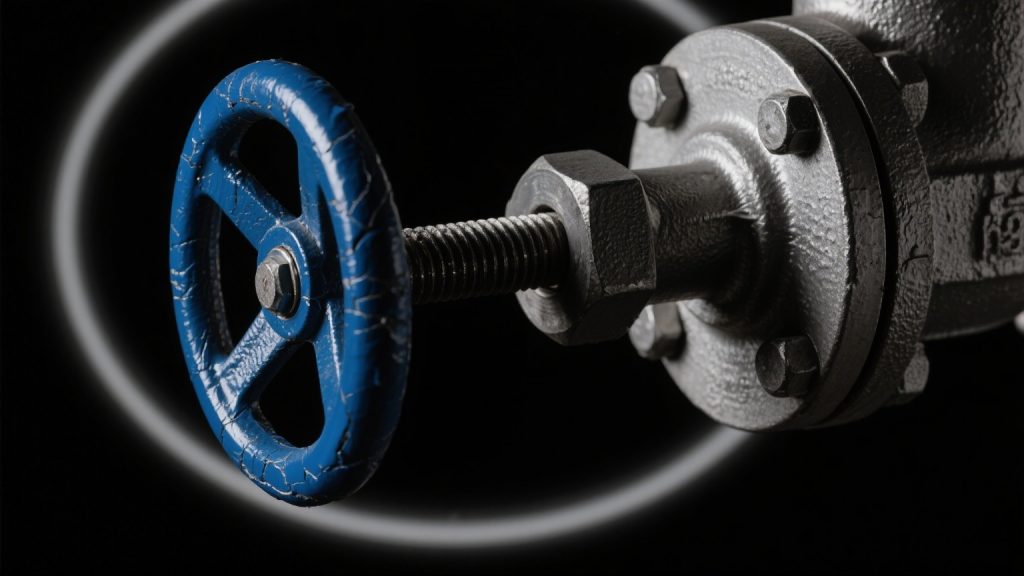

Globe Control Valves

Pin-point throttling, zero-leak shut-off — stable control in a single stroke.

Globe Control Valves——Born For Precise Modulation And Zero-leak Isolation

- Boiler-turbine main feedwater & desuperheating

- Oil-refining hydro/catalytic reactors at high P&T

- Nuclear secondary-loop feed & blow-down

Afraid of losing control? Pair a globe valve with pneumatic or electric actuation—smarter, faster, better, and rock-steady. Securing long-term stable control and safe sealing.

Globe Control Valves Series

Pneumatic Globe Control Valves

Driven by pneumatic actuators, the plug moves precisely for accurate throttling and tight shut-off under high-pressure, high-temperature conditions — delivering fast response, stable control, and maintenance-free performance.

Electric Globe Control Valves

Powered by electric actuators, the plug travels linearly for precise modulation and bubble-tight shut-off in demanding process lines — offering accurate control, easy automation, and long service life.

Typical Applications for Globe Control Valves in Flow Control

Petrochemical

In the petrochemical industry, globe control valves ensure stable flow control through erosion-resistant designs, enabling reliable process control and operational safety.

Energy & Power

In power and energy applications, globe control valves are primarily used for regulating steam and cooling water circulation, ensuring stable unit operation.

Pulp, Paper, and Metallurgical

In the pulp and paper and metallurgical industries, globe control valves provide precise control of pressure and flow.

Relational Guide

Relational Blog for You

What is a globe control valve?

A globe control valve is designed to accurately regulate fluid flow by moving a plug toward or away from the valve seat. It features high control precision and reliable sealing performance, making it ideal for stable and precise flow control applications.

What are the advantages and limitations of a globe control valve?

Globe control valves offer excellent throttling accuracy and tight shutoff, ensuring reliable performance. However, they typically have a higher pressure drop, making them less suitable for large flow rate systems.

What flow characteristics are available for globe control valves?

Globe control valves are available with different flow characteristics, which describe how the flow rate changes as the valve opens. The main options include linear, equal percentage, and quick opening, allowing precise flow control under different operating conditions.

Linear: Flow increases proportionally with valve travel, suitable for stable systems with constant pressure.

Equal percentage: Provides fine control at low openings and high capacity at large openings, ideal for variable pressure applications such as steam and temperature control.

Quick opening: Delivers high flow at small openings, mainly used for on-off or bypass service.

Flow characteristic comparison

| Flow Characteristic | Control Precision | Pressure Drop Adaptability | Typical Use |

|---|---|---|---|

| Linear | Medium–High | Low | Stable systems |

| Equal Percentage | High | Excellent | Steam / temperature control |

| Quick Opening | Low | Poor | On-off / bypass |

Where are globe control valves commonly used?

They are widely applied in power generation, petrochemical, and water treatment industries—fields that require precise flow regulation and stable operation.

How do I choose the right globe control valve?

Consider the medium type, working pressure, temperature, and desired flow control accuracy. For example, hygienic globe control valves are used in food and beverage applications with strict sanitary requirements, while corrosion-resistant globe valves are recommended for chemical or petrochemical processes with aggressive media. WANVALVE provides professional selection support and customized actuator options to ensure efficient performance.

Why choose WANVALVE globe control valves?

With over 15 years of manufacturing experience, WANVALVE offers durable, high-precision control valves with reliable sealing, moderate maintenance cost, and strong technical support. Our valves are built for long service life and superior control performance.