Pneumatic Butterfly Valves

Pneumatic butterfly valves offer fast actuation, reliable shut-off, and high flow capacity.

Why Pneumatic Butterfly Valves Are Widely Chosen?

Pneumatic butterfly valves combine large flow capacity, smooth frequent operation, and rapid emergency shut-off, offering the food and beverage industry a safer, more efficient, and cost-effective solution.

In addition, their simple structure, low cost, and easy maintenance make them a strong asset in building and sustaining stable automated production lines.

Pneumatic Butterfly Valves Series

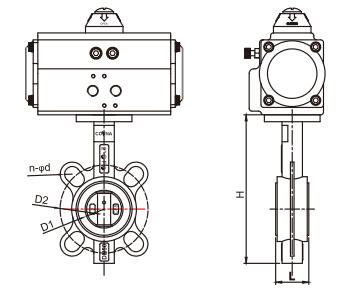

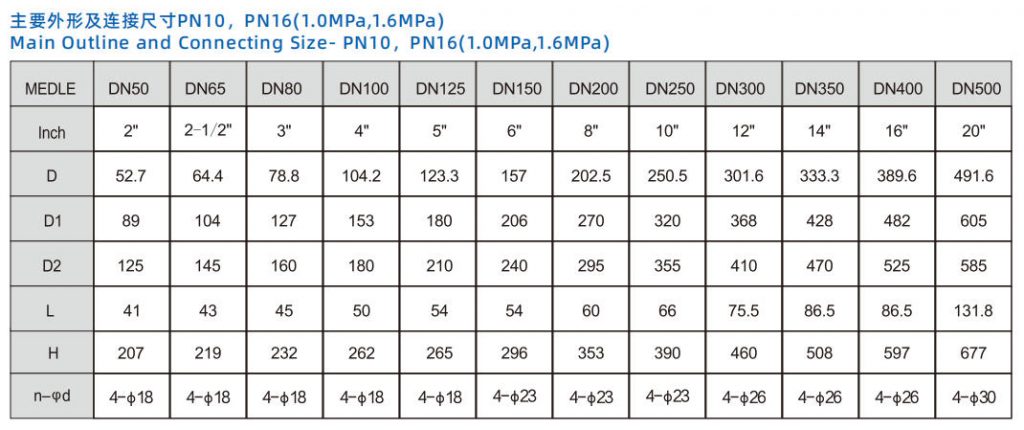

Pneumatic Wafer Stainless Steel Butterfly Valves

● Pressure: 10bar to 16bar (145psi to 232psi)

● Temperature: -5 to 180℃ (23 to 356℉)

● Connection: Wafer (ANSI/JIS/DIN/GB)

● Body Materials: SS304/316/316L

● Disc Materials: SS/Cast iron

● Sealing Materials: PTFE/EPDM

● Actuation: Single Acting or Double Acting

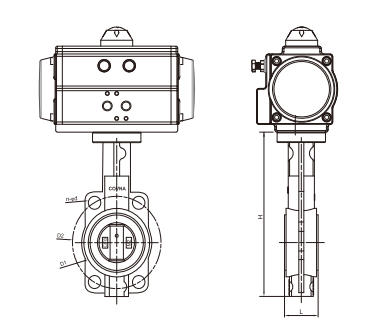

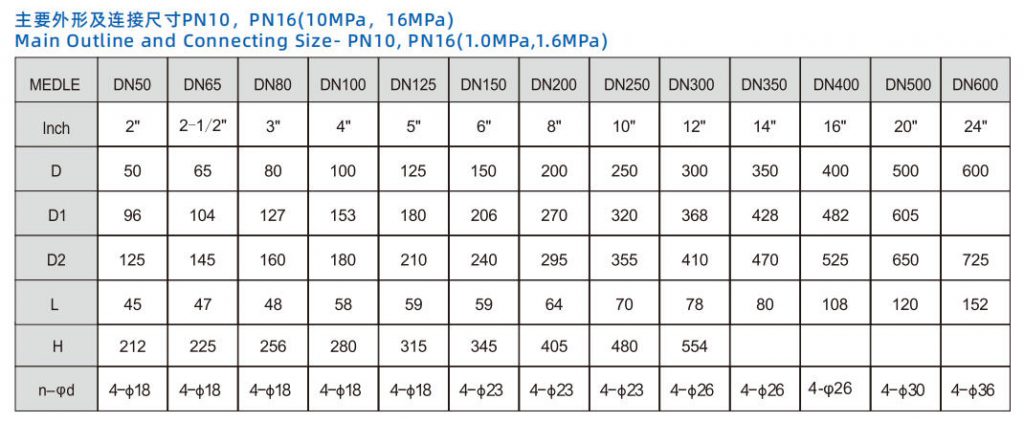

Pneumatic Wafer Cast Iron Butterfly Valves

● Pressure: 10bar to 16bar (145psi to 232psi)

● Temperature: -5 to 180℃ (23 to 356℉)

● Connection: Wafer (ANSI/JIS/DIN/GB)

● Body Materials: Cast iron

● Disc Materials: SS/Cast iron

● Sealing Materials: PTFE/EPDM

● Actuation: Single Acting or Double Acting

Pneumatic Flange Stainless Steel Butterfly Valves

● Pressure: 10bar to 16bar (145psi to 232psi)

● Temperature: -5 to 180℃ (23 to 356℉)

● Connection: Flanged (ANSI/JIS/DIN/GB)

● Body Materials: Stainless Steel

● Disc Materials: SS/Cast iron

● Sealing Materials: PTFE/EPDM

● Actuation: Single Acting or Double Acting

Pneumatic Flange Cast Iron Butterfly Valves

● Pressure: 10bar to 16bar (145psi to 232psi)

● Temperature: -5 to 180℃ (23 to 356℉)

● Connection: Flanged (ANSI/JIS/DIN/GB)

● Body Materials: Cast iron

● Disc Materials: SS/Cast iron

● Sealing Materials: PTFE/EPDM

● Actuation: Single Acting or Double Acting

Pneumatic Sanitary Clamp Butterfly Valves

● Pressure: 10bar to 16bar (145psi to 232psi)

● Temperature: -5 to 180℃ (23 to 356℉)

● Connection: Clamp

● Body Materials: Stainless Steel

● Disc Materials: Stainless Steel

● Sealing Materials: PTFE/VITON/Food Grade Silicone

● Actuation: Single Acting or Double Acting

Pneumatic Plastic Butterfly Valves

● Pressure: 10bar to 16bar (145psi to 232psi)

● Temperature: -5 to 80℃ (23 to 176℉)

● Connection: Flanged (ANSI/JIS/DIN/GB)

● Body Materials: UPVC/CPVC

● Disc Materials: UPVC/CPVC

● Sealing Materials: EPDM

● Actuation: Single Acting or Double Acting

Pneumatic Fluorine Lining Wafer Butterfly Valves

● Pressure: 10bar to 16bar (145psi to 232psi)

● Temperature: -5 to 180℃ (23 to 356℉)

● Connection: Wafer

● Body Materials: CI/WCB/Stainless steel

● Disc Materials: Fluorine Lining

● Sealing Materials: Fluorine Lining

● Actuation: Single Acting or Double Acting

Pneumatic Fluorine Lining Flanged Butterfly Valves

● Pressure: 10bar to 16bar (145psi to 232psi)

● Temperature: -5 to 180℃ (23 to 356℉)

● Connection: Flanged

● Body Materials: CI/WCB/Stainless steel

● Disc Materials: Fluorine Lining

● Sealing Materials: Fluorine Lining

● Actuation: Single Acting or Double Acting

What Are the Industrial Applications for Flow Capacity and Control?

Petrochmical

Pneumatic butterfly valves play a key role in petrochemical pipelines, providing reliable flow passage and quick shut-off for low-pressure, large flow capacity systems, while ensuring safe operation in explosion-proof environments.

Energy & Power

In hydropower, thermal power, and new energy generation, pneumatic butterfly valves are mainly applied to low-pressure, large-flow pipelines, offering flexible operation, rapid shut-off, and reliable safety protection.

Water Treatment

Pneumatic butterfly valves provide high flow, quick actuation, and low operating costs, making them ideal for desalination, circulation, and drainage systems.

Food & Beverage

Pneumatic butterfly valves can be applied in CIP and SIP cleaning systems, featuring fast actuation, high automation, reliable sealing, and a simple structure that allows thorough cleaning.

Other Relational Information

Pneumatic Wafer Butterfly Valve