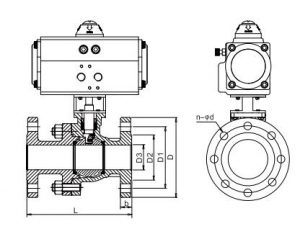

WANVALVE WP11-F-PTFE Pneumatic Fluorine Lining Ball Valve – Complete Product Description

The Pneumatic fluorine lining ball valve WANVALVE WP11-F-PTFE is engineered for demanding industrial applications. Featuring a fluorine lined valve, it provides superior corrosion resistance, making it ideal for handling acids and alkalis as well as other corrosive media. Constructed with duplex stainless steel, it delivers excellent mechanical properties and long service life, ensuring reliable operation under high temperatures and high pressures. Its smooth surface finish also facilitates easy cleaning and maintenance.

Technology Highlights

-

Fluorine Lining Technology: The PTFE fluorine lining forms a chemically inert barrier between the stainless steel body and the fluid. It resists strong acids, alkalis, and other corrosive media, reduces friction for smooth operation, and ensures long-term durability even under high temperatures. This lining also provides excellent resistance to oxidation and chemical degradation, making it suitable for a wide range of industrial chemicals beyond just acids and alkalis.

-

Pneumatic Actuation Technology: Designed for pneumatic actuation using compressed air, the valve provides precise, repeatable control. Configurations include single acting (spring return) and double acting (air-to-open/air-to-close), allowing integration into automated industrial systems.

-

Stainless Steel Selection: The duplex stainless steel body ensures high mechanical strength and resistance to corrosion, outperforming ordinary ball valves in demanding applications. Suitable for environments requiring martensitic or ferritic stainless steels, depending on the media and temperature conditions.

Key Features

-

Anti-Corrosive Design: Fluorine lining protects against strong acids, alkalis, and other corrosive media.

-

Reliable Pneumatic Operation: Precise flow control using compressed air.

-

Easy Maintenance: Smooth surface finish minimizes residue buildup.

-

Versatile Applications: Chemical, pharmaceutical, water treatment, and food production systems.

Technical Parameters

| Specification | Details |

|---|---|

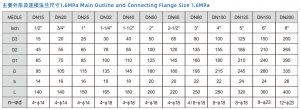

| Size | DN15 to DN200 (1/2” to 8”) |

| Pressure | 10bar to 16bar (145psi to 232psi) |

| Temperature | -5 to 180℃ (23 to 356℉) |

| Connection | Flanged |

| Body Materials | Duplex Stainless Steel |

| Actuation | Single Acting or Double Acting |

Applications of Pneumatic Actuated Ball Valves

These lined ball valves are ideal for corrosive media systems, including handling acids and alkalis. They are widely used in chemical plants, pharmaceutical facilities, water treatment, and industrial automation systems. The pneumatic actuated valve ensures precise control, while the fluorine lined valve maintains long-term reliability in harsh chemical environments.

For industry comparisons and more insights on fluorine lined valves, visit Pinch Lined Valves.

Maintenance & Service

To ensure optimal performance and extend the service life of the Pneumatic fluorine lining ball valve, follow these guidelines:

-

Routine Inspection: Check for leaks, wear, and valve actuation performance.

-

Cleaning: Utilize the smooth surface finish and fluorine lining to prevent residue accumulation from corrosive media.

-

Lubrication: Maintain pneumatic components with proper lubrication to ensure smooth operation.

-

Replacement of Wear Parts: Inspect and replace actuators, seals, and gaskets regularly to maintain resistant to corrosion and operational reliability.

-

Safe Handling: Follow safety protocols when servicing valves exposed to strong acids, alkalis, or other hazardous chemicals.

This structured maintenance ensures that the duplex stainless steel body and fluorine lined valve retain their mechanical properties, corrosion resistance, and smooth operation over long-term use.

Conclusion

The WANVALVE WP11-F-PTFE pneumatic fluorine lining ball valve combines advanced fluorine lining technology, robust duplex stainless steel construction, and pneumatic actuation to deliver exceptional durability, corrosion resistance, and operational precision. Suitable for strong acids, alkalis, and high-temperature processes, it provides long-lasting, reliable performance.

For additional valve solutions and technical insights, visit Beska Mold, a leading expert in industrial valve manufacturing.