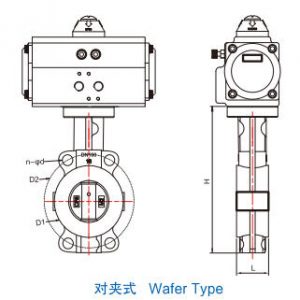

WANVALVE Pneumatic Wafer Fluorine Lining Butterfly Valve WP12-PTFE-W

The WANVALVE WP12-PTFE-W Pneumatic Fluorine Lining Butterfly Valve delivers exceptional corrosion-resistant performance for chemical and industrial flow systems. This fluorine lining wafer butterfly valve combines a durable valve body with a PTFE sealing surface to ensure tight shutoff and extended service life. Its pneumatic actuator provides efficient open and close control through a quarter turn motion, ideal for automation in corrosive medium pipelines.

Working Principle

This fluorine lined butterfly valve operates using a pneumatic actuator that converts compressed air energy into mechanical torque. When air pressure is applied, the actuator drives the valve stem to rotate the fluorine-lined disc by 90 degrees (quarter turn).

-

In the open position, the disc aligns parallel to the flow, allowing unrestricted passage of fluid.

-

In the closed position, the disc rotates perpendicular to the flow, pressing the sealing surface tightly against the seat to achieve a zero-leakage seal.

Thanks to the PTFE fluorine lining, the disc and seat resist corrosion and chemical attack even when handling aggressive substances such as nitric acid. The valve design ensures low operating torque, fast response, and reliable sealing performance under varying pressures and temperatures.

Key Features

-

Anti-Corrosive Structure: The fluorine lined valve provides robust resistance to acids, alkalis, and corrosive media, making it ideal for harsh process conditions.

-

Durable Valve Body: Constructed from stainless steel, ductile iron, or WCB, ensuring mechanical strength and thermal stability.

-

High Sealing Performance: PTFE sealing surface guarantees tight shutoff with minimal wear.

-

Efficient Pneumatic Actuation: Single or double acting pneumatic actuators deliver precise, rapid open and close operation.

-

Compact Wafer Style Design: Easy installation between pipeline flanges; also available in lug style for enhanced maintenance flexibility.

Technical Specifications

| Specification | Description |

|---|---|

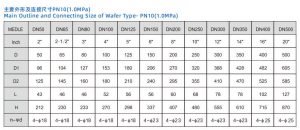

| Size | DN50 – DN500 (2” – 20”) |

| Pressure | 10bar – 16bar (145psi – 232psi) |

| Temperature | -5°C – 180°C (23°F – 356°F) |

| Connection | Wafer |

| Body Materials | CI / WCB / Stainless Steel |

| Disc Materials | Fluorine Lining |

| Sealing Materials | Fluorine Lining |

| Actuation | Single Acting / Double Acting |

Applications of Fluorine Lining Butterfly Valves

This fluorine lined wafer butterfly valve is ideal for:

-

Chemical and petrochemical plants

-

Water treatment and desalination systems

-

Food and pharmaceutical production lines

-

Acidic and corrosive media transport pipelines

For more professional resources on pneumatic butterfly valve design and component materials, visit Plumberstar.com — a trusted industry platform for precision flow control systems. Learn more about the working principles and advantages of pneumatic butterfly valves to better understand automation performance in corrosive environments.

Installation and Maintenance

The fluorine lined butterfly valve adopts a maintenance-friendly valve design with replaceable seats and actuators.

Proper flange alignment ensures optimal sealing performance. Periodic inspection of the fluorine lining prevents wear and maintains smooth quarter turn movement over long-term use.

For further technical insights into lined butterfly valves and industrial automation components, explore Metoree.com.

Quality Assurance

Each WANVALVE fluorine lined wafer butterfly valve is rigorously tested for pressure, torque, and leakage resistance. Its anti-corrosive stainless steel valve body, PTFE sealing surface, and high-grade pneumatic actuator meet international quality standards, ensuring dependable operation and safety in aggressive chemical environments.

Conclusion

The WANVALVE WP12-PTFE-W Pneumatic Fluorine Lining Wafer Butterfly Valve is a precision-engineered corrosion-resistant valve designed for efficient automation and durability. Its quarter turn pneumatic actuator, advanced fluorine lining, and robust valve design make it the ideal choice for industries handling corrosive mediums with high demands on sealing performance and longevity.