Selecting the right pneumatic globe control valve ensures your process runs safely and efficiently. In industries relying on control valves, even small mismatches can cause pressure drops, leaks, or unstable flow, especially in systems using compressed air, steam, or liquids, the right globe valve helps the process controller maintain accurate operation. Modern options like the type 2301 2-way globe control valve feature stainless steel bodies for durability, while double acting operated valves provide precise flow control.

Understanding Pneumatic Globe Control Valves

A pneumatic globe control valve uses compressed air to move an internal plug up or down, controlling the flow accurately. It uses compressed air to move an internal plug up or down, controlling how much fluid passes through the valve body. The valve gets its name from its rounded, globe-shaped body, which provides excellent flow regulation and sealing performance.

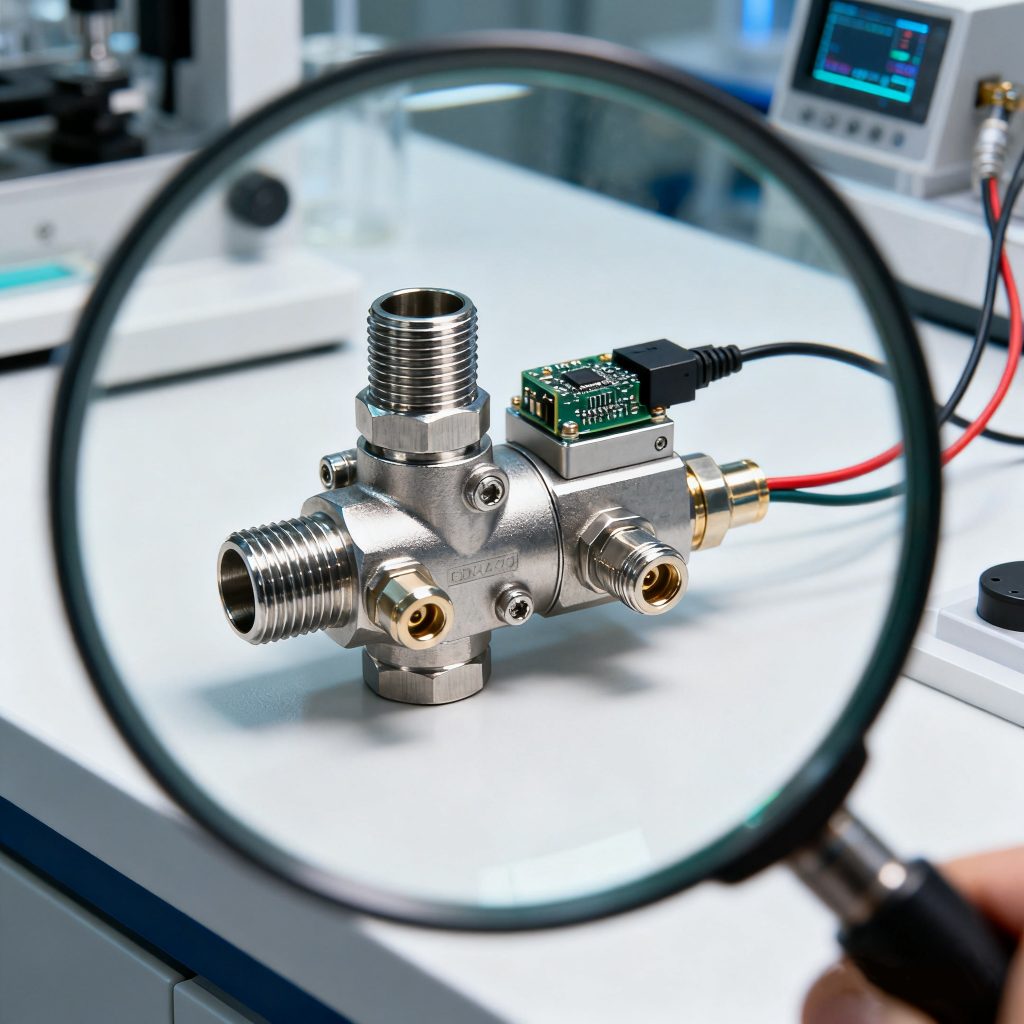

Inside the valve, several key parts work together — the stainless steel body ensures strength and corrosion resistance, while the trim (including plug, stem, and seat) determines how precisely the flow is controlled. The actuator converts air pressure into mechanical motion, and in many systems, a process controller sends a signal to adjust the valve position automatically.

For example, the type 2301 2-way globe control valve is widely used in chemical plants, water treatment, and HVAC systems. Its double acting actuator offers fast response and accurate flow control, making it a trusted choice among operated valves for mid-pressure applications.

Define Your Application

Before choosing any pneumatic globe control valve, it’s essential to define the exact conditions in which it will operate. Different applications require different valve designs, materials, and actuation methods. Start by identifying the type of medium—is it liquid, gas, or steam? Each medium behaves differently under pressure and temperature, which affects how your control valves perform.

Next, analyze operating conditions. High-pressure steam systems, for instance, need stainless steel valves that can handle heat and corrosion. In contrast, low-pressure air systems might only need lightweight valves for compressed air control. Also, determine if the valve will be used for continuous modulation or on-off operation. Continuous flow control requires more precise positioning and often benefits from a double acting actuator design.

Finally, consider the environmental factors—humidity, dust, or chemical exposure. The right material and sealing type ensure that your operated valves last longer and maintain stable performance, even in harsh industrial settings.

Selecting Valve Body and Trim Materials

The material of a pneumatic globe control valve determines its strength, corrosion resistance, and long-term reliability. Choosing the wrong material can lead to leaks, rust, or even total valve failure. For most industrial systems, stainless steel remains the preferred choice—it resists corrosion from chemicals, moisture, and high temperatures while offering excellent mechanical durability.

Other materials, such as carbon steel or cast iron, can be used for less demanding environments where cost is a major factor. However, when working with aggressive fluids or high-pressure steam, stainless steel ensures both safety and longer service life. Inside the valve, the trim (plug, stem, seat) also plays a key role. These parts control the flow directly and must resist erosion and wear.

Some modern control valves, like the type 2301 2-way globe control valve, feature a precision-engineered stainless steel trim that reduces noise and improves flow control accuracy. When choosing operated valves for your system, always match materials to your medium, pressure, and temperature requirements to ensure consistent performance.

Determine Valve Size and Flow Capacity

Sizing a globe control valve correctly is one of the most important steps in achieving efficient flow control. A valve that is too large will cause poor control sensitivity, while an undersized valve can restrict flow and increase energy costs. To select the proper size, engineers usually calculate the flow coefficient (Cv), which indicates how much fluid can pass through the valve under specific conditions.

The process controller plays a role here as well — it determines how the control valve responds to pressure and flow changes in real time. For example, in a compressed air system, a double acting actuator may open or close the operated valve more smoothly, providing stable control even with fluctuating air supply.

A practical tip: always size the valve to operate between 30% and 80% open at normal flow. Advanced products like the type 2301 2-way globe control valve come with optimized internal flow paths that enhance Cv value and minimize pressure loss — ideal for industries requiring stable and accurate flow, such as food processing, chemical, and energy systems.

Control Valve Actuation Methods

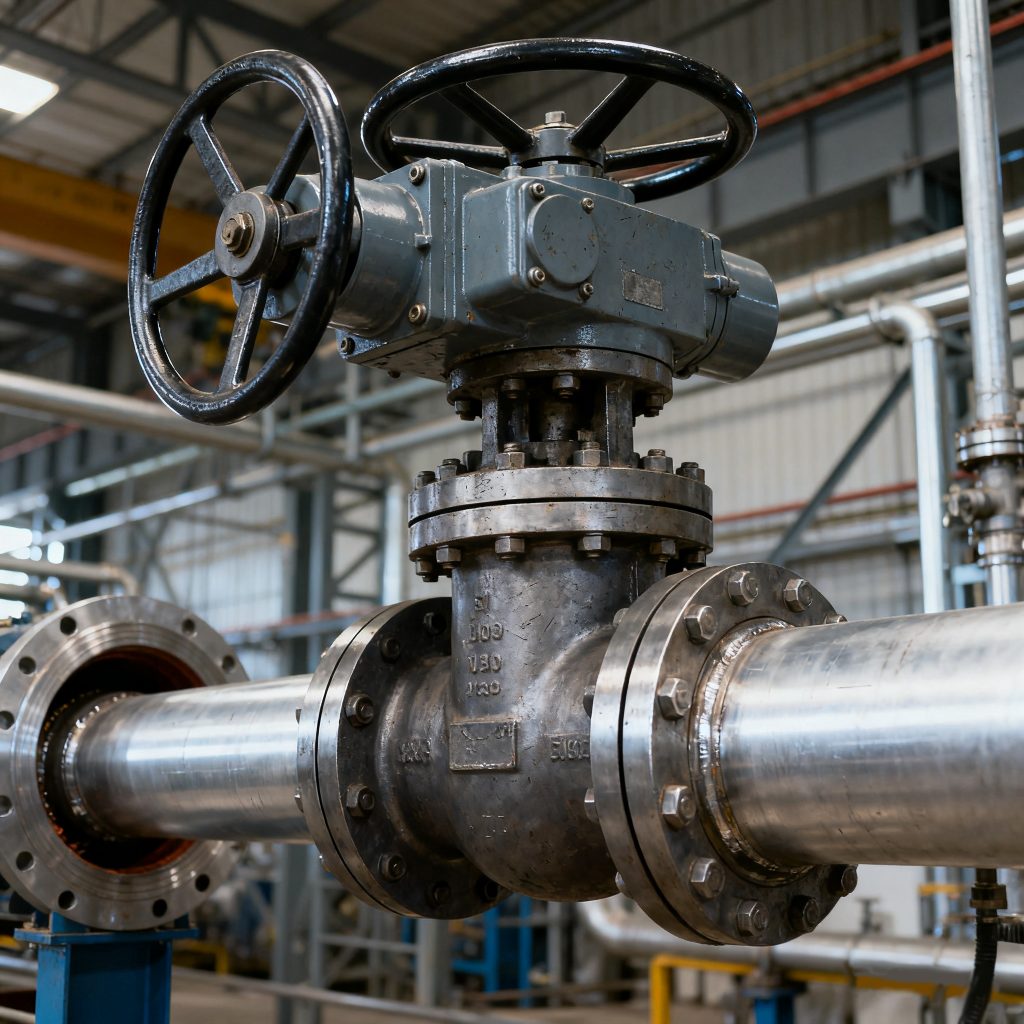

The actuation method of a globe control valve determines how it opens, closes, and adjusts to maintain stable flow control. For industrial buyers, understanding the difference between manual, electric, and pneumatic (air-operated) valves is essential for making the right choice.

Among these, pneumatic globe control valves are the most popular due to their reliability, fast response, and compatibility with compressed air systems. They use air pressure to move the valve stem, allowing precise regulation of flow. Within pneumatic actuators, there are two main types: single acting and double acting.

- A single acting actuator uses air pressure to move in one direction and a spring to return to its original position. It’s energy-efficient and ideal for fail-safe operations.

- A double acting actuator uses air pressure for both directions of movement. This provides more stable performance and stronger torque, especially suitable for large valves or high-pressure applications.

Control Characteristics and Performance

In flow control systems, every globe valve has a distinct control characteristic, which defines how the valve’s opening position affects the flow rate. Selecting the correct characteristic curve is essential for achieving smooth, accurate, and energy-efficient operation.

The two most common types are linear and equal percentage characteristics:

- Linear control means that the flow rate changes proportionally with the valve stroke. This type is ideal for processes where system pressure drop remains nearly constant.

- Equal percentage control delivers small changes in flow at low openings and larger changes at high openings. It’s better suited for systems with significant pressure variations or processes requiring fine control.

In a pneumatic globe control valve, the process controller constantly adjusts the valve position based on feedback signals, ensuring stable output even under dynamic conditions. Advanced models like the type 2301 2-way globe control valve offer customizable control curves that optimize both responsiveness and stability.

Material selection also impacts performance. Stainless steel valve bodies maintain consistent performance under corrosive or high-pressure environments.

For professional buyers seeking performance benchmarks and testing standards, BCST Valve and GlobalSpec offer comprehensive technical resources and product comparisons.

Valve Material Selection

Choosing the right valve material is a vital decision that affects the globe control valve’s lifespan, safety, and reliability. The material must resist corrosion, withstand pressure and temperature fluctuations, and remain compatible with the process fluid.

The most commonly used materials for pneumatic globe control valves include stainless steel, carbon steel, cast iron, and bronze alloys.

- Stainless steel is preferred for harsh or corrosive environments.

- Carbon steel offers mechanical strength at a lower cost.

- Cast iron is ideal for low-pressure applications.

- Special alloys like Hastelloy or Monel are used in extreme cases.

Installation and Maintenance Considerations

Proper installation and maintenance are crucial to ensure your globe valve and operated valves function reliably over time. Key points for installation include correct flow direction, sufficient space for maintenance, and clean compressed air supply.

Maintenance tips:

- Check for leaks, wear, and corrosion regularly.

- Lubricate moving parts and inspect actuators.

- Keep spare seals and gaskets on hand to reduce downtime.

Conclusion

Selecting the right pneumatic globe control valve is key to safe, efficient, and reliable process operation. By evaluating your application, choosing the appropriate materials, sizing the valve correctly, and selecting the right actuation type, you can ensure precise flow control and long-term performance.

Modern valves, such as the type 2301 2-way globe control valve with stainless steel construction and double acting operated actuators, offer durability, fast response, and easy maintenance. Proper installation, routine maintenance, and attention to control characteristics complete the recipe for consistent efficiency and reduced downtime in industrial and commercial systems.

About Products

Thanks for reading our article. If you want to learn more about our products and technologies, check out our Globe Control Valves for detailed specifications and options.