Electric explosion-proof ball valves play a key role in factories where liquids and gases travel through long pipelines every day. They prevent sparks, reduce leak risks, and let engineers manage equipment remotely with confidence.

They are widely used in chemical plants, refineries, and oil & gas fields. Websites like xintaivalves.com show many real examples of electric ball valves in industry.

How Electric Explosion-Proof Ball Valves Work

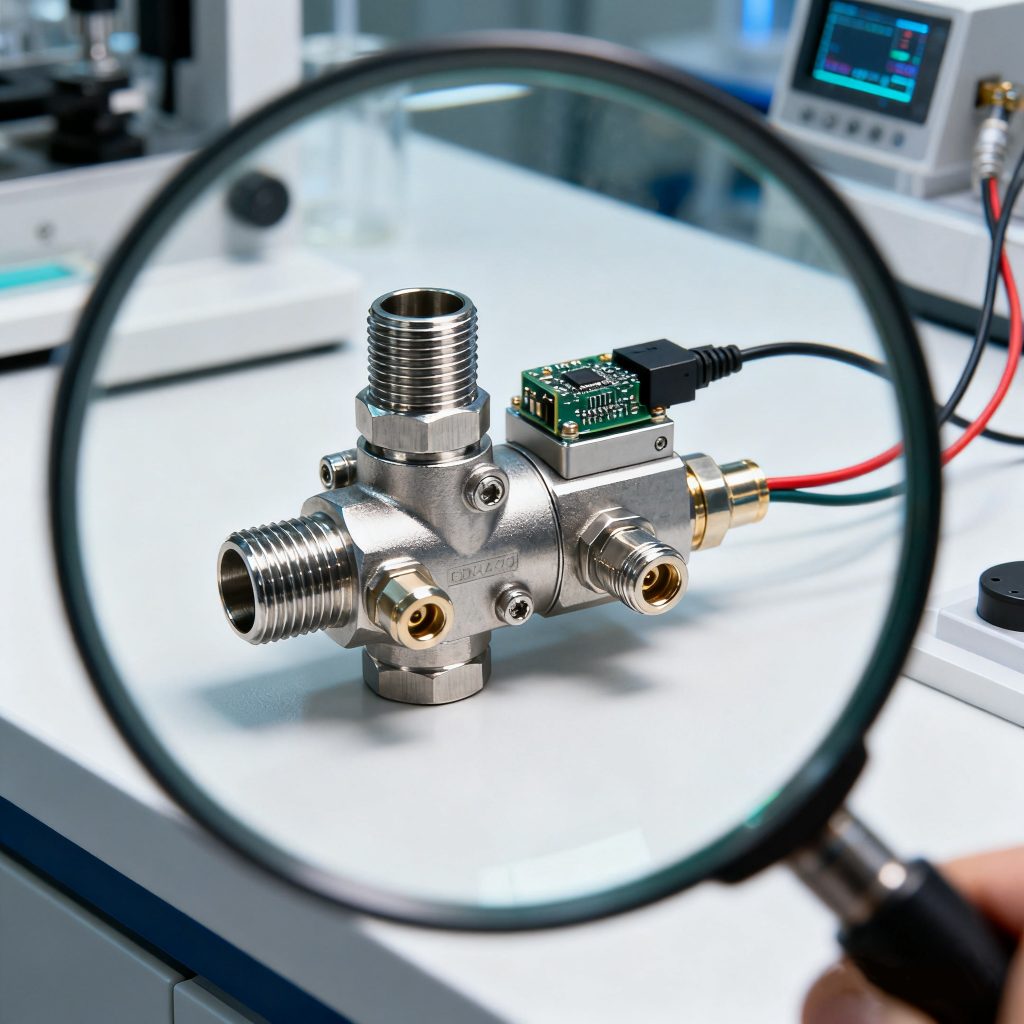

This valve has three main parts: the ball valve itself, the electric actuator, and the flanged connection. When the actuator turns the ball, the flow path opens or closes. The full port design allows liquid or gas to move smoothly without slowing down.

The explosion-proof electric enclosure prevents sparks from escaping, keeping workers and equipment safe. A mounting pad helps the actuator stay firmly fixed on top of the valve, ensuring stable operation.

Technical Specifications and Key Features

| Category | Details |

|---|---|

| Materials | Stainless steel, carbon steel |

| Valve Type | Full port ball valve |

| Actuation | Electric actuator or explosion-proof actuators |

| Connection | Flanged ends for strong and stable installation |

| Temperature Range | Suitable for high-temperature media such as steam or hot oil |

| Applications | Water, oil, gas, chemicals, corrosive fluids |

Fact one: Explosion-Proof Design Ensures Maximum Safety

These valves are built to prevent sparks, arcs, or heat from igniting dangerous gases in the environment. Explosion-proof housings meet ATEX and IECEx certification standards.

They are used in chemical plants, oil & gas facilities, and other hazardous areas where safety is the highest priority.

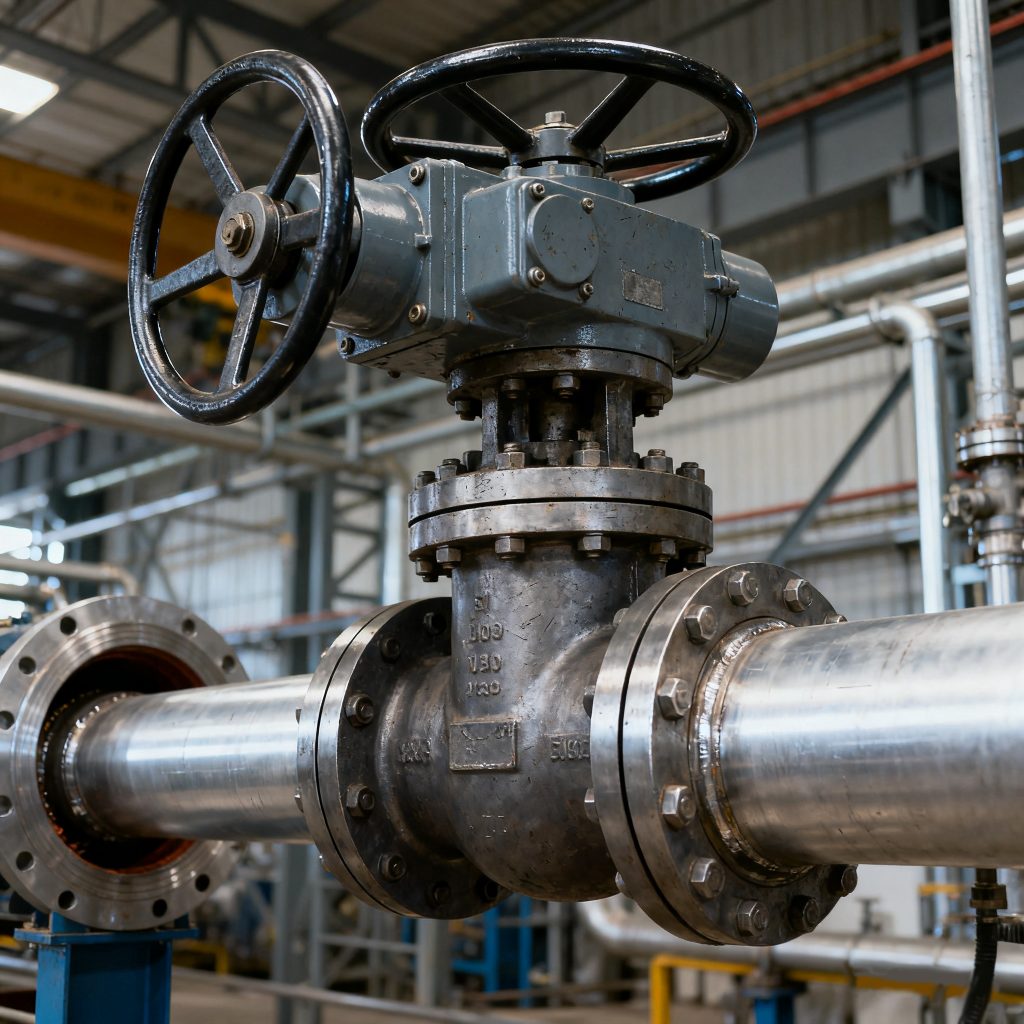

Fact two: Flanged Connection Simplifies Installation and Maintenance

The flanged ends provide a secure and stable connection to the pipeline.

This makes installation easier, especially for large pipe sizes.

Flanged connections also allow quick disassembly for inspection or replacement, reducing downtime in industrial systems.

Fact Three: Electric Actuation Provides Precise and Reliable Flow Control

Electric actuators allow accurate control of the valve position.

They support remote operation and can be integrated into automated systems such as PLC or DCS.

For hazardous environments, explosion proof actuators ensure safe and stable performance.

Fact Four: High-Pressure and High-Temperature Compatibility

These stainless steel ball valves are built to handle steam, hot oil, and high-pressure gas.

The valve body and internal ball are strong enough to resist bending or cracking.

The explosion proof electric actuator can operate smoothly even under high temperature conditions, making the valve suitable for heavy-duty industries.

Fact Five: Low Maintenance Requirements and Long Service Life

The simple structure of full port ball valves reduces wear and tear.

Stainless steel components resist corrosion, allowing long-term operation with minimal maintenance.

Electric actuators are designed for long life cycles, helping factories avoid unplanned shutdowns.

Fact Six: Compatibility With Various Media

Electric flanged explosion-proof ball valves can handle water, oil, gas, steam, and many chemical liquids.

Different materials and seals can be customized to suit corrosive or high-temperature applications.

This makes the valve flexible for different industries and working conditions.

Fact Seven: Energy Efficiency and Automation Integration

Electric actuators consume less energy than pneumatic ones in many applications.

They can be connected to safety systems, emergency shutdown devices, and industrial automation platforms.

Integration helps factories improve safety and reduce energy waste.

Applications in Modern Industry

These explosion-proof flanged ball valves are used in chemical production lines, petrochemical plants, oil & gas networks, steam pipelines, and high-pressure water systems.

They are also found in automated control environments where accurate valve operation is critical.

Real-world use cases can be seen on platforms such as torksystems.com.

Conclusion

Electric explosion-proof ball valves deliver dependable safety, stable performance, and precise flow control. With stainless steel bodies, full port construction, and explosion-proof electric actuators, they operate confidently even in harsh industrial conditions. This makes them a smart and durable choice for hazardous environments that require automation, long service life, and reliable protection.

About Products

We appreciate your time! Discover more about our products and see how Electric Explosion-Proof Ball Valve can enhance safety and performance in your system.