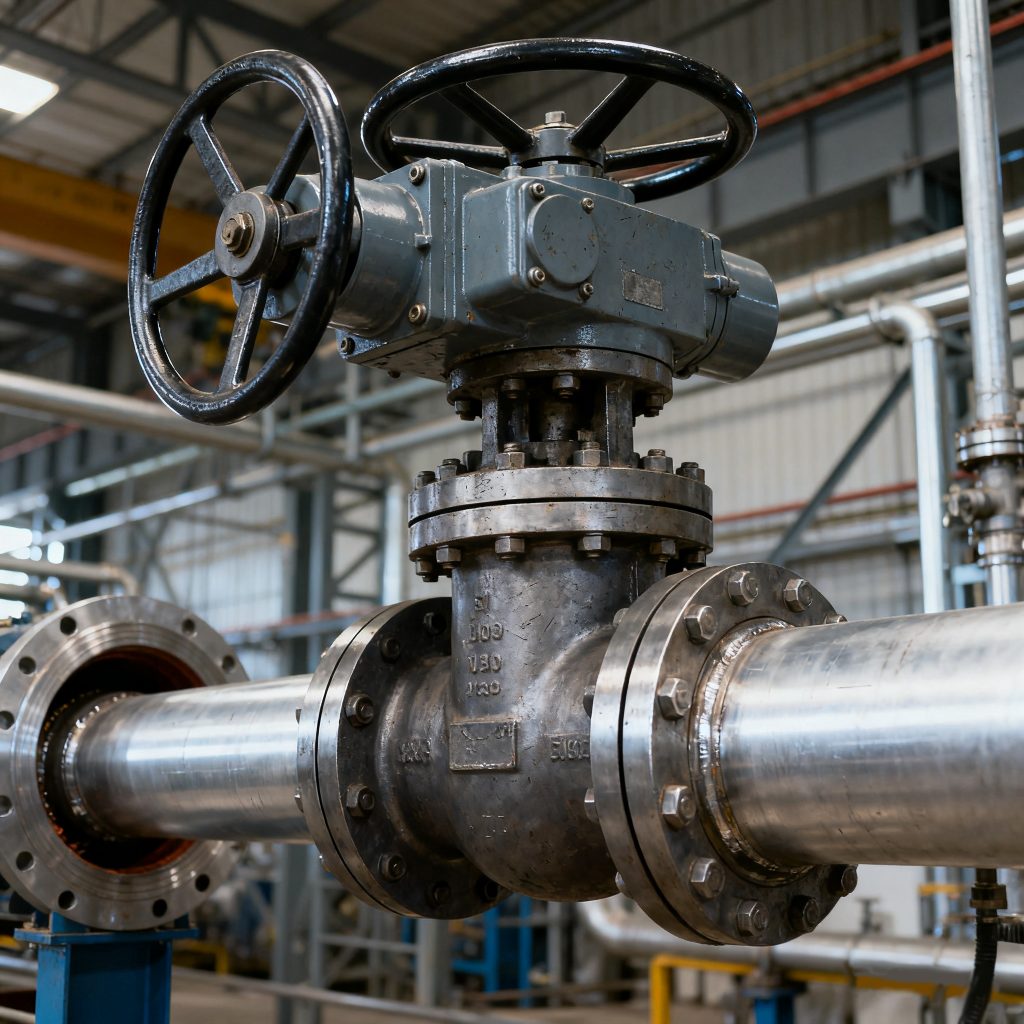

Electric globe control valves are essential in industrial applications for precise flow regulation. Their electrically actuated design ensures accurate and reliable flow control, improving system efficiency and reducing the need for maintenance. When choosing the right globe control valve, it’s important to understand the application and the specific control requirements to ensure smooth and reliable performance.

For instance, in HVAC systems, these valves help regulate temperature in chilled water and heating loops. To explore more about the technology driving these systems, visit belimo.com.cn.

Understanding Electric Globe Control Valves

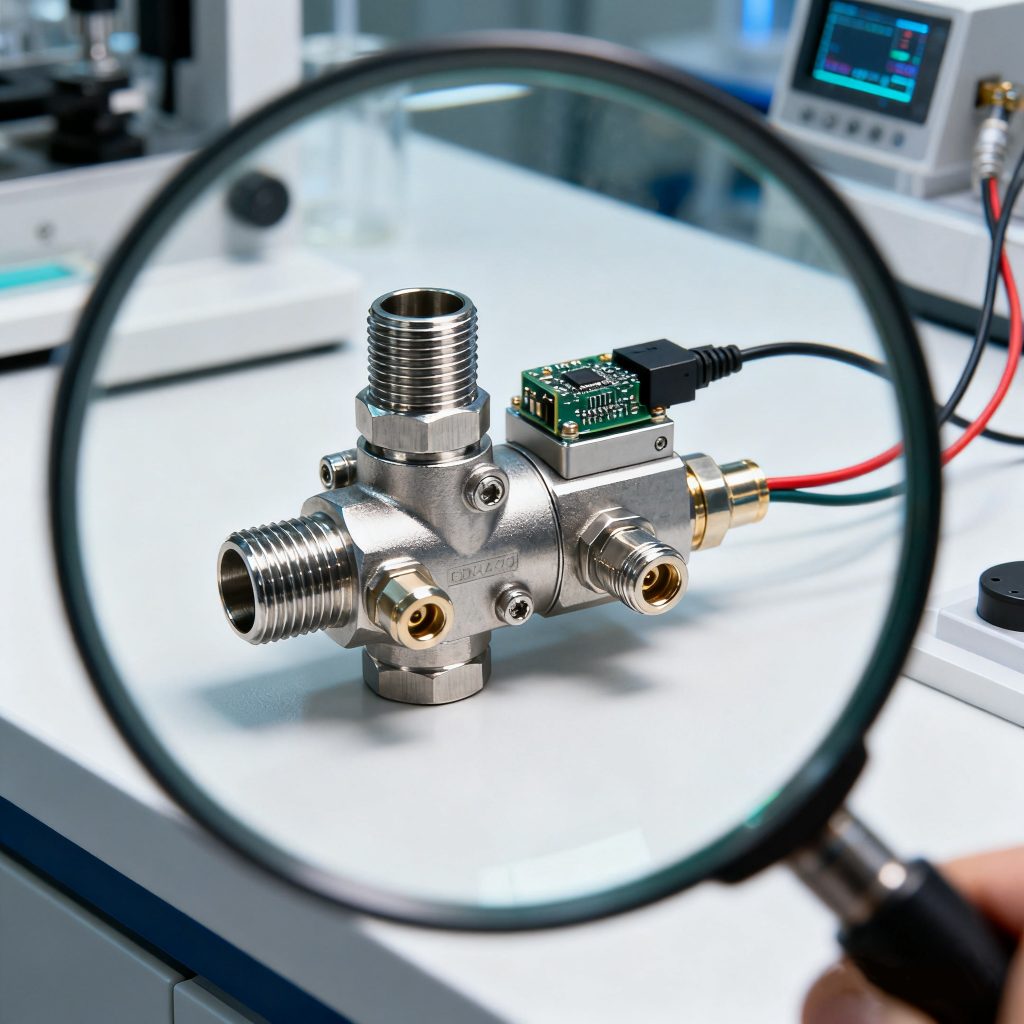

Electric globe control valves are designed to regulate the flow of fluids by adjusting the position of a movable plug inside the valve body. When the actuator receives an electrical signal, it moves the valve stem to modulate the flow accordingly. This design enables smooth control over a broad range of conditions, making these valves ideal for applications that require precise, stable control.

Unlike basic on/off valves, globe control valve systems can make precise adjustments, maintaining steady flow even when changes in pressure or load occur. If you’re looking for more details on how electrical actuation impacts flow control, check out the resources available at valves-actuator.com.

Applications of The Electric Valve

- Chemical & Petrochemical Systems: Electric globe control valves are key in chemical and petrochemical systems, where controlling temperature, pressure, and flow accurately is vital. These valves regulate corrosive or reactive media, ensuring system stability and preventing accidents. Their ability to fine-tune flow minimizes leaks, blockages, and inefficient operations, crucial for safety and productivity.

- Power Generation & Steam Systems: In power plants, electric globe control valves regulate feedwater and steam flow to boilers and turbines, maintaining optimal pressure and temperature for energy production. They also control steam conditioning and auxiliary circuits, preventing thermal shock, reducing equipment wear, and improving energy efficiency. In turbine bypass systems, globe valve control ensures safe, reliable operation.

- Water & Wastewater Treatment: In water and wastewater plants, electric globe control valves regulate flow during filtration, dosing, and stabilization. They ensure consistent flow for efficient treatment, whether handling clean water or semi-dirty fluids, optimizing energy use and improving overall system performance. Consistent flow is key for effective disinfection and filtration.

- Oil, Gas & Pipeline Networks: Electric globe control valves are vital for maintaining pressure balance and regulating flow in oil, gas, and pipeline networks. They ensure that fluids such as oil, gas, or slurry flow at a controlled rate, preventing damage and reducing the risk of pressure surges or cavitation. These valves also allow precise flow adjustments, enhancing pipeline integrity and reducing energy losses.

- HVAC & Building Automation: In HVAC systems, electric globe control valves regulate the flow of chilled or hot water in heating, ventilation, and air-conditioning loops. They help optimize energy use and maintain indoor comfort year-round. For district heating or cooling systems, globe valve control is critical for balancing temperature across large areas, ensuring efficient energy consumption.

Sizing an Electric Globe Control Valve

- Flow Requirements: The first step in sizing an electric globe control valve is determining the system’s flow needs. This includes identifying maximum, minimum, and typical flows. A well-sized valve ensures optimal performance—too large can lead to unstable throttling at low flows, while too small restricts flow, impacting efficiency. Proper sizing is essential for ensuring reliable open and closed functionality throughout the valve’s long-term operation, enabling smooth globe control.

- Cv Selection: The Cv (flow coefficient) is key in valve sizing, determining the valve’s ability to pass flow at a specific pressure drop. A mismatched Cv can cause instability or flow restriction. Accurate Cv calculation ensures proper flow control, allowing the valve to perform effectively under the required pressure conditions, ensuring precise globe valve operation.

- Valve Size vs. Pipeline Conditions: You don’t determine valve size by pipe size alone; you must match it with the system’s pressure, flow rate, and operating conditions. You should consider factors like pressure drop and cavitation potential. Choosing a valve too large leads to poor throttling, while one that’s too small results in wear. Proper size matching ensures efficient, long-term valve control.

- Pressure and Temperature Ratings: The valve’s pressure and temperature ratings must match the system’s operational conditions. Whether it’s a high-pressure or high-temperature application, selecting the right valve body and material ensures optimal, reliable performance. Overstressing valves leads to failure, so matching the correct ratings is crucial for effective globe control valve operation.

- Flow Characteristics: The flow characteristic defines how the flow rate changes with actuator movement. For precise modulation, the correct characteristic—linear, equal-percentage, or quick opening—is crucial. An equal-percentage valve, for example, is ideal for varying loads, ensuring stable flow control. This is vital for achieving optimal globe valve control in dynamic system conditions.

Selecting Materials and Actuators

- Body and Trim Materials: Engineers should design the valve body and trim materials to withstand repeated opening and closing cycles, particularly in demanding applications with harsh chemicals or extreme temperatures. Choosing durable materials ensures that the valve maintains reliable performance during repeated opening and closing cycles.

- Electric Actuator Requirements: The actuator must provide sufficient torque to control the valve accurately under varying pressure conditions. Selecting the correct actuator size ensures the valve operates efficiently without overloading or malfunctioning under stress.

- Power Supply Compatibility and Signal Types: It’s crucial to ensure that the actuator’s power supply and control signals (e.g., 4-20mA, digital) are compatible with the system’s control platform. Proper integration enhances control accuracy and system performance.

Best Practices for Choosing an Electric Globe Control Valve

- Ensure Compatibility with Process Conditions: It’s essential to match the valve with the system’s pressure, temperature, and fluid characteristics to ensure optimal performance. Improper compatibility can lead to inefficient operation and system failures.

- Prevent Oversizing and Instability: Oversizing the valve can lead to instability during the open and closed cycles, causing poor throttling control at lower flow rates. Proper sizing is essential to maintaining stable open and closed operations, ensuring smooth flow regulation.

- Select an Actuator that Matches Valve Torque Needs: The actuator must be capable of providing the required torque for the valve to function properly. Torque requirements depend on factors like valve size, pressure, and fluid type.

- Consider Installation Space and Environmental Exposure: The valve and actuator should be suitable for the installation space and environment. Exposure to harsh conditions like extreme temperatures, moisture, or dust may require additional protection.

- Prioritize Maintainability and Long-Term Reliability: Choose valves with components that are easy to maintain or replace, ensuring long-term performance and minimizing downtime.

- Verify Compliance with Industry Standards: Make sure that the valve meets industry standards and certifications for pressure, temperature ratings, and environmental conditions. This ensures safe operation and compliance with regulations.

FAQS

1. How do I choose the right electric globe control valve?

To select the right valve, consider the system’s flow rate, pressure, and temperature. Ensure the valve size and Cv (flow coefficient) match the system’s needs for stable performance.

2. How do I size an electric globe control valve?

Valve size depends on the system’s pressure, flow rate, and operating conditions. Choose the right size to avoid flow restrictions or pressure loss, ensuring efficient operation.

3. How do I choose the correct Cv value for the valve?

Cv determines how much flow the valve can handle. Calculate it based on your system’s flow and pressure drop to ensure stable and effective flow control.

4. How do I choose the right flow characteristic?

Choose between linear, equal-percentage, or quick-opening flow characteristics based on your system’s needs. For varying loads, equal-percentage valves provide better flow control.

5. How can I ensure the valve lasts long?

Pick durable materials and actuators suited to the system’s conditions. Regular maintenance checks are also important to keep the valve working well over time.

Conclusion

Choosing the right electric globe control valve is essential for efficient, reliable operation during opening and closing cycles, reducing maintenance and optimizing performance. By considering factors such as sizing, actuator selection, and material compatibility, engineers can ensure that the valve functions effectively throughout its service life. For more information on valve types and applications, you can visit fgttw.com.

About Products

Looking for more information on how to optimize your system? Check out our Globe Control Valves for detailed specifications and options.