A valve with pneumatic actuator is a valve operated by compressed air, where air pressure is used to open, close, or regulate flow. In industrial automation, engineers commonly refer to this configuration as a pneumatic valve.

This combination is widely used because it offers fast response, reliable performance, and suitability for demanding operating conditions. Compared with electrically actuated solutions, pneumatic actuators perform consistently in high-cycle operation, harsh environments, and applications with strict safety requirements.This article explains how valves with pneumatic actuators are configured, how they work, and where they are commonly applied in industrial systems.

Why Use Pneumatic Actuators on Valves?

Pneumatic actuators convert air pressure into linear or rotary motion. The concept is straightforward, yet extremely effective in industrial practice.

First, pneumatic systems respond quickly. When compressed air is supplied, the actuator quickly reaches its end position. This rapid action makes pneumatic valves ideal for high-cycle operations, where slower alternatives would wear out from frequent opening and closing.

Second, pneumatic actuators perform reliably in harsh environments. Dirt, moisture, and temperature fluctuations have limited impact on mechanical air-driven systems. Compared to electrically actuated valves, pneumatic solutions often require less protection in outdoor or heavy-duty installations.

Safety is another key factor. Pneumatic actuators can include defined fail-safe positions. If the air supply is lost, the valve automatically moves to a predetermined open or closed state. This feature is crucial for emergency shutdown systems and helps explain why pneumatic valves are widely used in process safety applications.

Finally, pneumatic actuation is well suited for hazardous or potentially explosive areas. Without electrical sparks at the actuator level, pneumatic valves are frequently preferred in chemical processing, oil and gas, and similar industries.

Common Configurations of Valve with Pneumatic Actuator

Pneumatic actuator configuration directly affects how the valve behaves in service. The choice between different designs influences response, safety, and control accuracy.

Spring-Return Pneumatic Actuator

A spring-return actuator uses air pressure to move the valve in one direction, while an internal spring returns it when air is released. This simple mechanism defines the valve’s fail-safe position.

Depending on the installation, the valve can be designed as fail-open or fail-close. Loss of air supply automatically triggers the spring action. No external control is required.

Typical applications include emergency shutdown systems and safety-critical pipeline applications, where predictable response during power or air failure is essential.

Double-Acting Pneumatic Actuator

A double-acting actuator uses air pressure for both opening and closing movements. There is no spring involved. Instead, air is alternately supplied to each side of the piston.

Compared to spring-return designs, double acting actuators provide more consistent force throughout the stroke and greater stability for large or high-torque valves. They are commonly used in automated systems with reliable air supply.

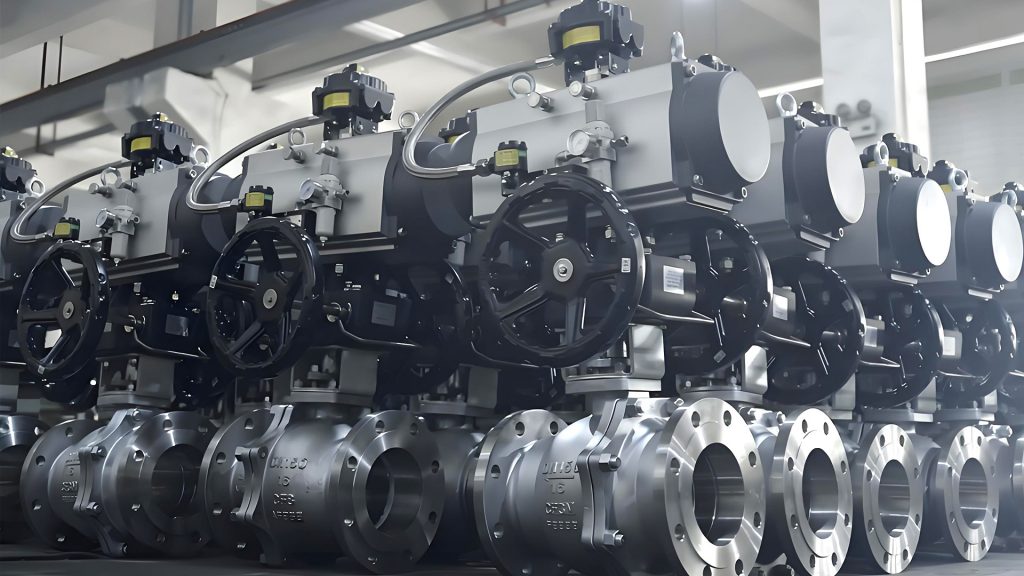

Typical applications include high-cycle automated processes and situations requiring continuous and stable valve operation. Large butterfly valves and actuated ball valves often use double-acting configurations for this reason.

On-Off Valves with Pneumatic Actuators

On-off pneumatic valves operate in two discrete positions: fully open or fully closed. The actuator drives the valve quickly to its end position, providing clear isolation.

Response speed and shut-off performance are key advantages. Materials such as stainless steel are often selected for valve bodies to handle corrosion and aggressive media.

These valves are widely used for pipeline isolation and remote on-off control systems, where fast actuation and reliable sealing are more important than precise throttling.

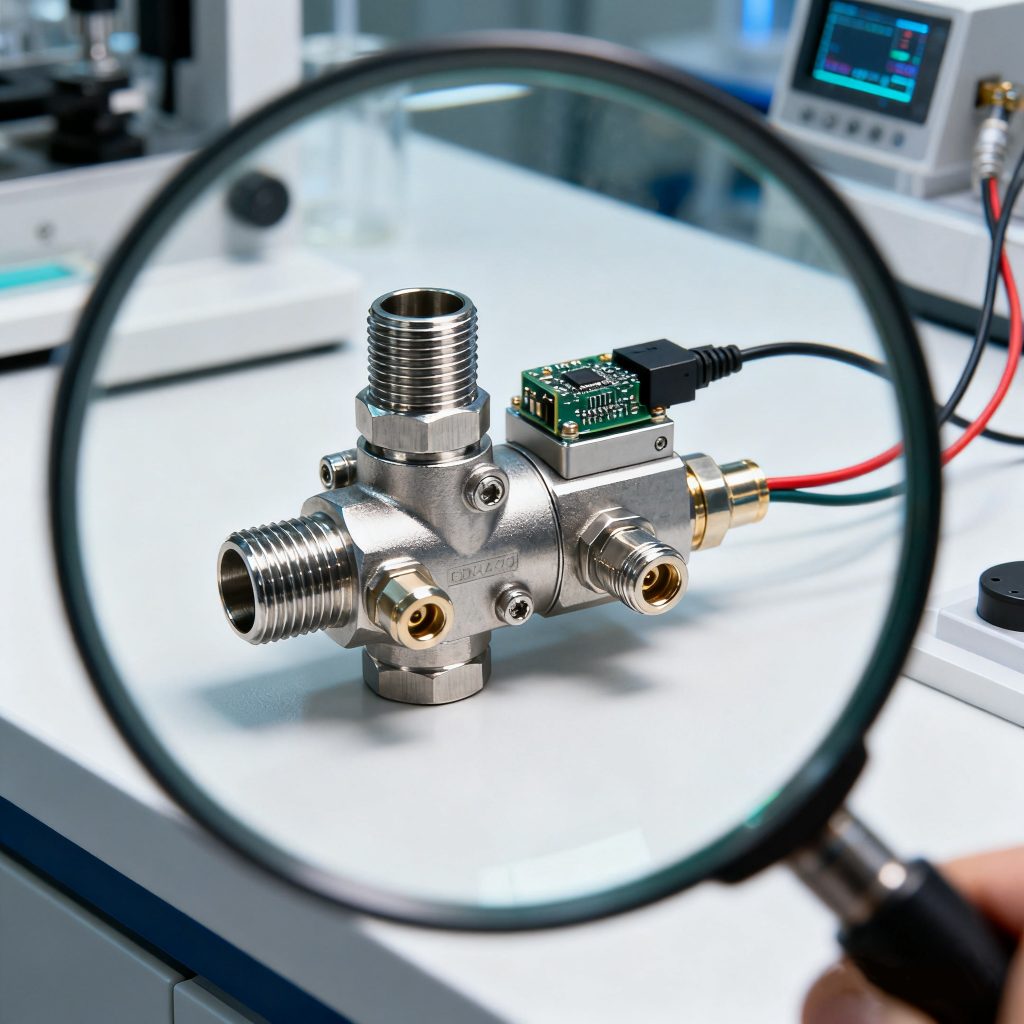

Modulating (Control) Valve with Pneumatic Actuator

In modulating service, the valve position is not limited to open or closed states. Instead, it continuously adjusts to regulate flow, pressure, or temperature.

This level of control is achieved through valve positioners, which precisely control actuator movement based on control signals. Pneumatic actuators remain popular in control applications due to their smooth response and compatibility with analog or digital control systems.

Typical uses include flow control loops, pressure regulation, and temperature balancing in process systems.

For deeper technical references on pneumatic control concepts and actuator integration, manufacturers such as Bürkert provide detailed application insights on their regional technical portals (see examples at burkert.co.nz).

Valve Types Commonly Equipped with Pneumatic Actuators

Several valve designs commonly pair with pneumatic actuation, depending on control requirements.

- Globe valves are selected when precise flow control is needed. Their geometry supports accurate modulation.

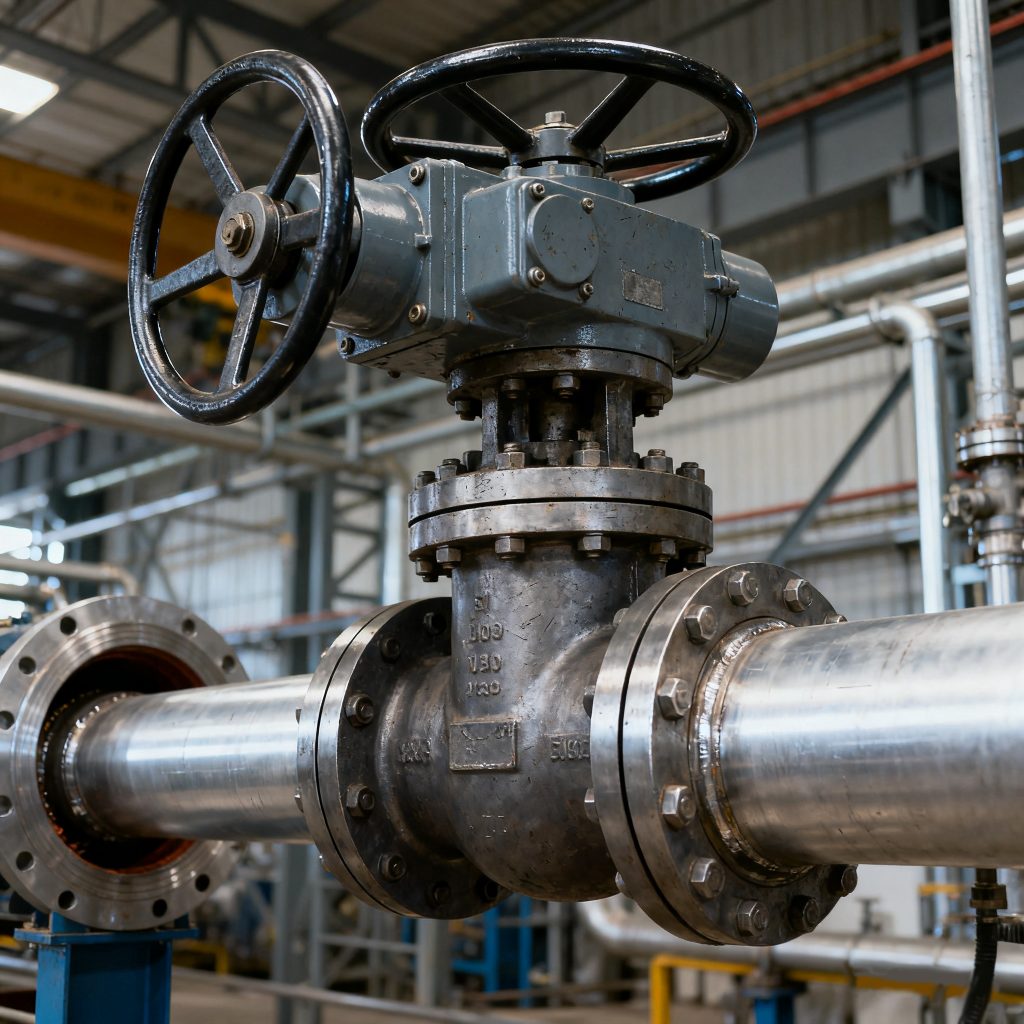

- Butterfly valves are favored for large-diameter pipelines. Their compact design, combined with pneumatic actuators, allows quick operation with relatively low torque requirements.

- Ball valves offer tight shut-off and high-cycle performance. Pneumatically actuated ball valves are widely used in isolation service, especially when fast and repeatable operation is needed.

Valve selection always depends on process media, control function, and operating conditions rather than actuator type alone.

Typical Application Series

- Valves with pneumatic actuators are commonly found in high-cycle automated process systems, where durability and repeatability are critical.

- They are also widely applied in large-diameter pipeline control, where manual operation is impractical and electric solutions may become bulky or expensive.

- In hazardous or explosive environments, pneumatic actuation remains a preferred choice due to its inherent safety characteristics. Emergency shutdown and other safety-related systems continue to rely heavily on pneumatic designs.

Key Considerations When Selecting a Valve with Pneumatic Actuator

Selection begins with defining the required control function. On-off applications have different needs than modulating control loops.

Fail-safe position is equally important. The valve must move to a safe state if air supply is lost.

Operating pressure and temperature limits of both the valve and actuator must be evaluated carefully. In addition, the availability and quality of instrument air can directly affect system performance and maintenance requirements.

Conclusion

A Valve with pneumatic actuator offer a proven balance of speed, safety, and reliability. Their ability to operate using compressed air makes them suitable for demanding industrial environments where electrically actuated solutions may introduce risks or limitations.

Selecting the right actuator configuration and valve type is essential for safe and reliable operation. When properly matched to the application, pneumatic valves remain one of the most dependable components in modern industrial automation systems.

About Products

If you want to dive deeper into configurations and specifications of valve with pneumatic actuator, our pneumatic actuated valves page provides a useful reference.