Choosing the right industrial globe control valve is very important for industries like oil and gas, chemical processing, power generation, water treatment, and HVAC systems. A properly selected valve makes your system run more efficiently, keeps it safe, and reduces maintenance costs over time. This guide explains the main types of globe valves, what to consider when choosing one, and how they are used in different industries. With this information, you can pick the best valve for your system.

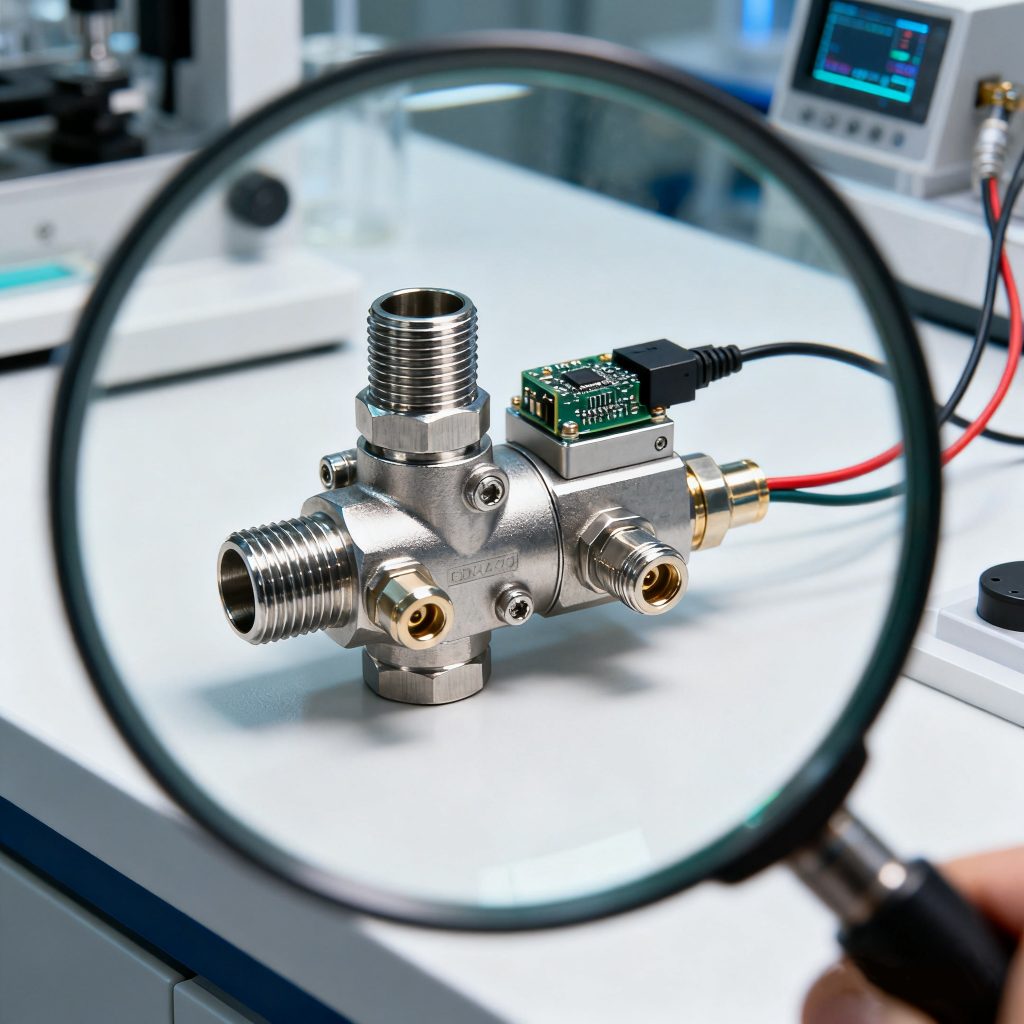

1.What is a Globe Control Valve?

A globe control valve is an industrial valve made to control the flow of fluid in pipelines. Unlike ball valves or gate valves, which mainly turn the flow on or off, globe valves are very good at precise flow control and reliable shutoff. Their design lets you adjust the flow often without losing performance. That is why they are commonly used in high pressure oil and gas pipelines, chemical plants, power generation systems, and water treatment facilities.

2.When Should You Use a Globe Valve?

A globe valve is the best choice when a system needs accurate flow control rather than just on/off operation. They are often used in high pressure and high temperature pipelines, such as steam systems, oil and gas operations, and chemical processing.

For corrosive or abrasive fluids, like those in water treatment plants or slurry pipelines, a stainless steel globe valve or an angle pattern globe valve offers better reliability and a longer service life. Choosing the right valve helps your system work efficiently and reduces downtime in industrial operations.

3.Types of Globe Valves

- Straight Pattern Globe Valve – Provides reliable flow control for general industrial pipelines and standard fluid applications.

- Angle Pattern Globe Valve – Handles slurry, abrasive, or corrosive fluids, making it ideal for chemical plants and water treatment facilities.

- Y-Pattern Globe Valve – Reduces pressure drop while keeping efficient flow regulation, commonly used in high pressure or steam systems.

Need more reliable Globe Control Valves for your system? Learn more here.

4.How to Choose the Right Globe Valve

- Flow control vs shutoff – Decide whether precise throttling or primarily tight shutoff is required for your system.

- Pressure & temperature ratings – Ensure the valve can safely handle your system’s operating conditions.

- Material selection – Stainless steel, carbon steel, or special alloys may be necessary for compatibility with your fluid.

- Valve sizing (Cv) – Correct flow coefficient sizing ensures efficiency and prevents energy loss.

- Actuation type – Choose between manual, electric, pneumatic, or hydraulic actuators depending on automation needs.

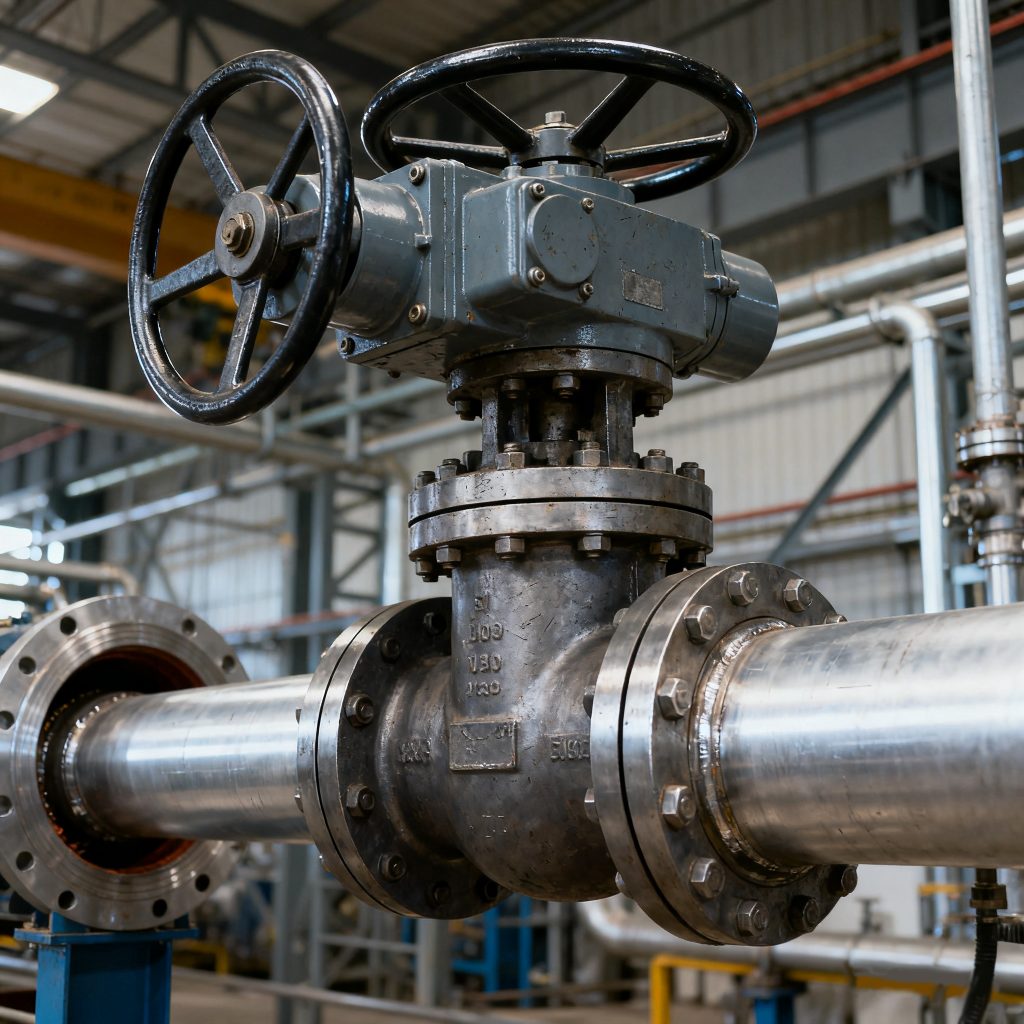

5.Industry Applications

- Oil & Gas – Used in high pressure pipelines and refinery systems where safety and reliability are critical.

- Power Generation – Common in steam service and boiler control systems.

- Water Treatment – Offers corrosion resistance and long operational life.

- Chemical Processing – Handle corrosive and high-pressure fluids where safety and material resistance are crucial. For in-depth guidance on control valve design and ammonia process safety, refer to AmmoniaKnowHow.

- HVAC Systems – Maintains energy efficiency and stable temperature control.

6.Globe Valve vs Ball and Gate Valves

- Globe Valve – Best for precise flow control and reliable throttling.

- Ball Valve – Designed for quick shutoff with minimal effort.

- Gate Valve – Ideal for full flow, low resistance in open/close service.

Choose a globe valve when accuracy and regulation are essential, while ball or gate valves are better suited for simple on/off functions.

7.Mistakes to Avoid

- Ignoring pressure and temperature limits, which can compromise performance.

- Choosing incompatible materials for corrosive or abrasive fluids.

- Overlooking maintenance and lifecycle costs, which can increase operational expenses and downtime.

8.Quick Checklist Before Buying

- Ensure the valve fits your pressure and temperature range.

- Confirm material compatibility with your fluid or media.

- Verify valve size and flow coefficient (Cv) are correctly calculated.

- Check that the actuation type matches your manual or automated system needs.

Conclusion

Selecting the right globe valve ensures efficient operation, reliable shutoff, and reduced lifecycle costs. By understanding valve types, key selection factors, and industry-specific applications, you can make an informed decision and optimize the performance of your industrial system.

About Products

If you are interested in our business, products, or technical solutions, please visit our globe control valve product section for more information.