Choosing the best manual valve for your system might sound technical, but it’s simpler than it seems. The right valve helps your system run smoothly, ensures efficient flow control, and reduces maintenance headaches. Understanding manual valve types and their industrial applications makes choosing the right valve easier. A reliable valve supplier can also guide you to the best solution for your system.

1.What Is a Manual Valve?

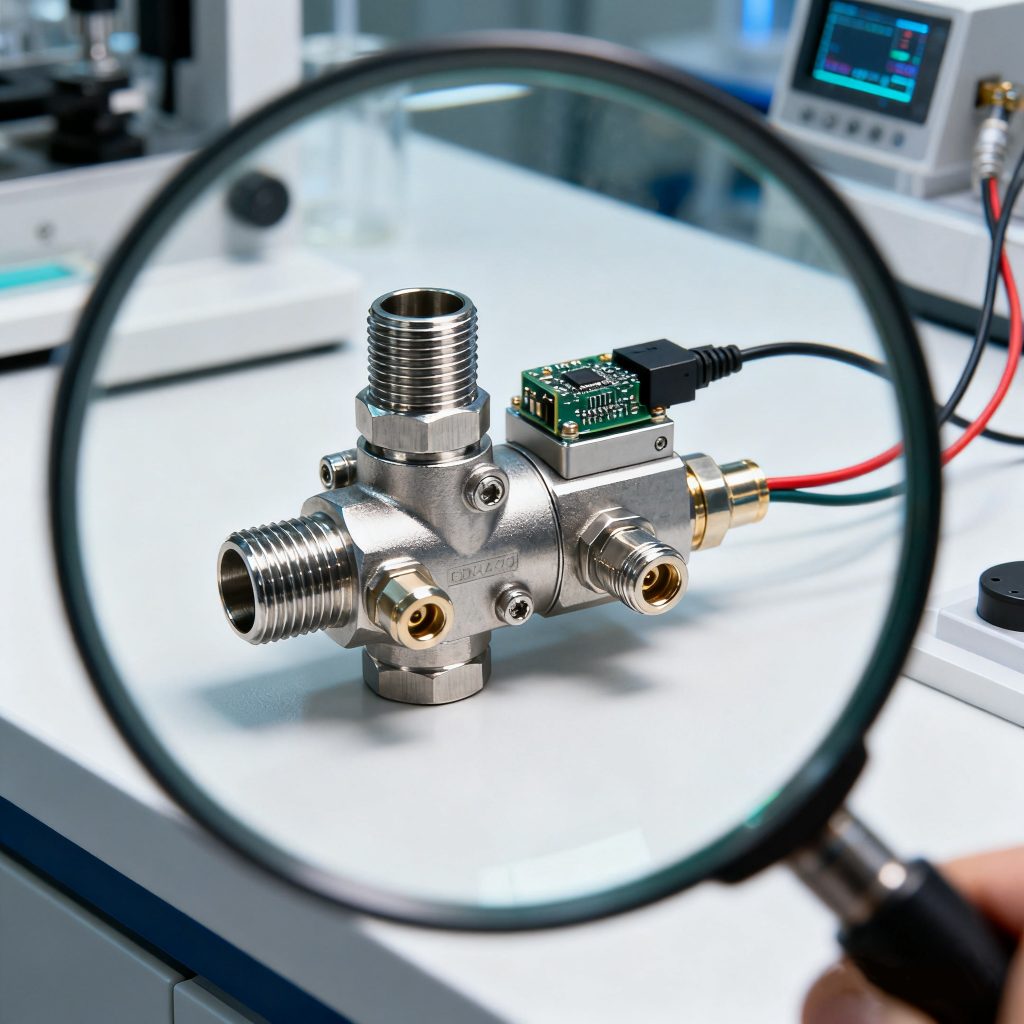

- A manual valve is a simple device that lets you control the flow of liquids, gases, or steam by hand.

- Instead of using motors or automation, you turn a handle, lever, or handwheel to open or close it.

- Manual valves are popular because they are easy to use, reliable, and require minimal maintenance.

- It also ensures smooth flow control in any application.

2.Manual Valve Types and Applications

Understanding the different types of manual valves helps you pick the right one for your system. For deeper insight into valve mechanisms and performance standards, explore technical resources from Metoree. In the right setting, every valve type keeps its system running safely and reliably.

- Ball valves: Quick to open and close with a simple quarter turn. Ideal for controlling liquids or gases efficiently. Their design reduces pressure drop and ensures reliable shutoff.

- Butterfly valves: Light, easy to install, and cost-effective. They are suitable for large pipelines and provide smooth operation with minimal maintenance.

- Gate valves: Fully open or fully closed, perfect for isolating flow in pipelines. They offer minimal resistance when fully open, ensuring efficient fluid transport.

- Globe valves: Provide precise control over flow, often used where regulating pressure or flow is critical. Their structure allows fine adjustments.

- Check valves: Automatically prevent fluid backflow, maintaining system safety. They require no manual operation and improve operational reliability.

Selecting the right valve type ensures smooth flow control, improves system performance, and reduces maintenance needs.

3.How to Choose the Best Manual Valve for Your System

When selecting the best manual valve for your system, consider these key points to ensure optimal performance and reliability:

- Application requirements: Match the valve type to water, gas, oil, or slurry. Correct matching ensures efficient flow control.

- Pressure and temperature: Ensure the valve can handle both normal and peak conditions. Proper pressure and temperature handling prevents leaks and extends valve life.

- Material selection: Choose from stainless steel, cast iron, or carbon steel, balancing durability and cost. Selecting the right material improves long-term reliability.

- End connections: Flanged, threaded, or welded connections should fit your system requirements. Proper connections reduce maintenance issues.

- Maintenance: Easy serviceability and availability of spare parts reduce downtime. Regular maintenance ensures consistent manual valve operation.

4.Manual Valve Materials: Strength, Cost, and Reliability

The material of a manual valve affects its performance, lifespan, and suitability for different applications:

- Stainless steel: Corrosion-resistant and durable. Can handle high pressure and high temperature, making it ideal for demanding industrial applications.

- Cast iron: Affordable and suitable for low to medium-pressure water or HVAC systems. Best for non-corrosive environments.

- Carbon steel: Strong and cost-effective. Requires protective coating for corrosion resistance, commonly used in oil, gas, and steam applications.

- Alloy or specialty materials: Designed for extreme conditions, offering high performance for petrochemical, power generation, and offshore systems.

Choosing the right material ensures long-lasting manual valve operation and reduces maintenance needs.

5.Manual Valves for Different Industries

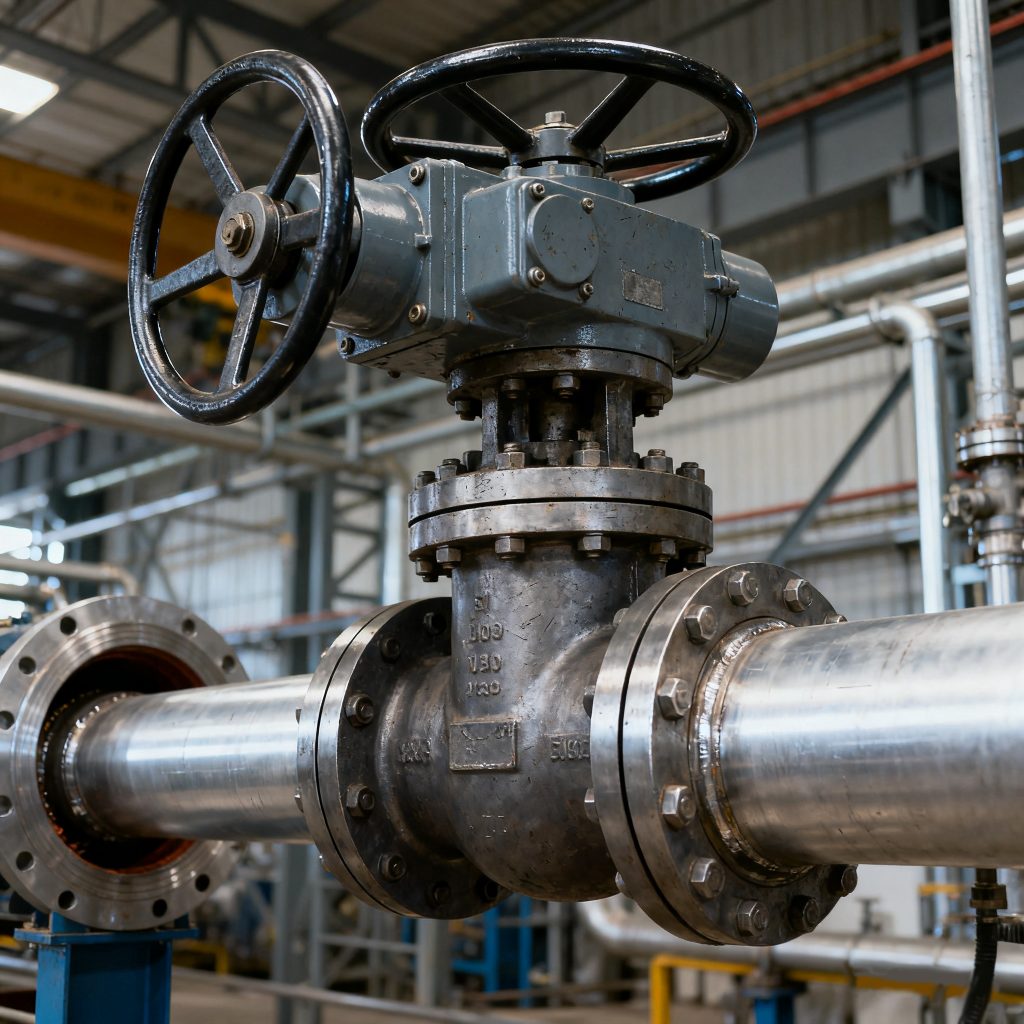

Manual valves are used across various industries, each with specific requirements for flow control and durability:

- Water & HVAC: Butterfly and gate valves are commonly used. They offer cost-effective operation and reliable control of water or air flow.

- Oil & Gas: Ball and gate valves are preferred. Their design withstands high pressure and provides durable performance in demanding conditions.

- Power Generation: Globe valves offer precise flow control, while check valves prevent backflow and protect equipment.

- Chemical & Medical: Diaphragm and stainless steel globe valves resist corrosion and maintain hygiene standards for sensitive applications.

- Food & Beverage: Stainless steel and butterfly valves ensure sanitary compliance while providing efficient flow control.

Selecting valves suited to each industry improves system efficiency, reliability, and safety.

6.Quality Standards and Manufacturer Reliability

Ensuring the quality of manual valves is essential for safety, efficiency, and long-term performance:

- Certifications: Look for API, ANSI, and ISO certifications. These standards confirm that valves meet strict safety and durability requirements.

- Trusted suppliers: Choose experienced manual valve suppliers who provide expert guidance and reliable products.

- Reliability: High-quality valves reduce maintenance, minimize downtime, and ensure consistent flow control in any system.

Using certified valves from trusted manufacturers helps protect your investment and maintain smooth system operation.

7.Balancing Cost, Maintenance, and Long-Term Value

When selecting a manual valve, it’s important to balance upfront cost, maintenance, and long-term value to ensure the best investment:

- Upfront vs. total cost: Cheap valves may save money initially but often require frequent replacements or repairs. Investing in durable, high-quality valves saves money over time.

- Maintenance: Valves that are easy to service and have readily available spare parts reduce downtime and maintenance effort.

- Durability: High-quality valves last longer, maintain efficient flow control, and protect your system from unexpected failures.

Balancing these factors ensures that your manual valve investment provides long-term reliability and performance.

Conclusion

Selecting the best manual valve for your system ensures safety, efficiency, and long-term reliability. By understanding manual valve types and applications, material durability, industry requirements, and balancing cost with maintenance, you can make an informed choice. Working with a trusted manual valve supplier and certified, high-quality valves guarantees smooth operation and protects your investment.

About Products

Thank for reading our article. Want to explore more details? Visit our manual valves section for full specs and options.