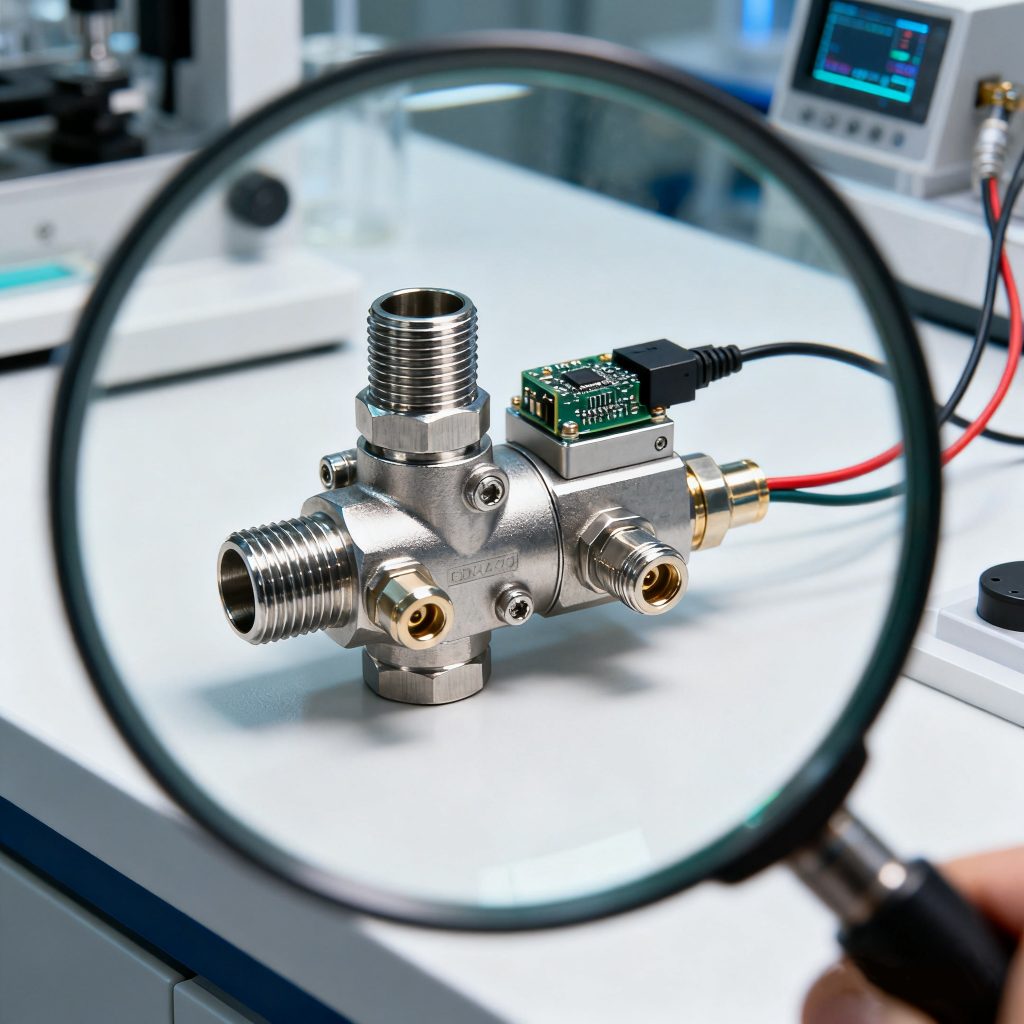

Solenoid valves may be small, but they control the flow of fluids and gases in countless systems. From automotive fuel management to water treatment and HVAC, the right component ensures efficiency, reliability, and smooth operation. Choosing wisely can prevent costly problems and keep systems running flawlessly. This guide is designed to help you understand which type of control valve is best for automotive, water treatment, or HVAC applications.

1.Understanding Solenoid Valves

Solenoid valves use an electromagnetic coil to control whether fluids or gases can pass through a channel, opening or closing the flow path as needed. Despite its compact size, this device plays a vital role in many systems, from fuel delivery in cars to water treatment and building climate control.

Depending on the application, systems may use direct-acting solenoids for quick response or pilot-operated ones for larger flow capacity. Another important distinction is whether the unit is normally open or normally closed. This determines if fluid can pass through when no power is applied.

Understanding these fundamentals is essential before selecting the most suitable control device for your application.

2.Key Selection Factors

When choosing the right control unit, several conditions must be evaluated:

· Type of medium – Whether the flow involves clean water, compressed air, steam, or chemical solutions directly affects material and design choices.

· Operating pressure and temperature – Each device is engineered for specific ranges; operating beyond the rated limits may lead to early wear or fluid leakage.

· Flow rate requirements – A valve that is too small restricts performance, while an oversized one may waste energy and reduce efficiency.

· Response time – Automotive systems, such as variable valve timing solenoids or purge valves, often require fast actuation.

· Power supply compatibility – Matching coil voltage (AC or DC) with the system’s electrical setup ensures safe and reliable operation.

Considering these factors together helps ensure long-lasting performance and stable flow control.

3.Automotive Applications

In automotive engineering, solenoid valves play a central role in regulating fuel delivery, emissions, and cooling circuits.

· Fuel Injection and Variable Valve Timing: Solenoid valves, including the variable valve timing solenoid, precisely regulate fuel and valve timing, improving engine efficiency and performance.

· Emission Control: Valves like purge solenoid valves and EGR solenoids help manage exhaust gases, keeping vehicles compliant with environmental regulations.

· Cooling and HVAC Systems: These valves manage coolant flow and cabin heating or air conditioning, ensuring comfortable and efficient operation.

Choosing the right automotive solenoid valve, such as a variable valve timing solenoid or purge solenoid valve, ensures optimal engine performance, energy efficiency, and system reliability.

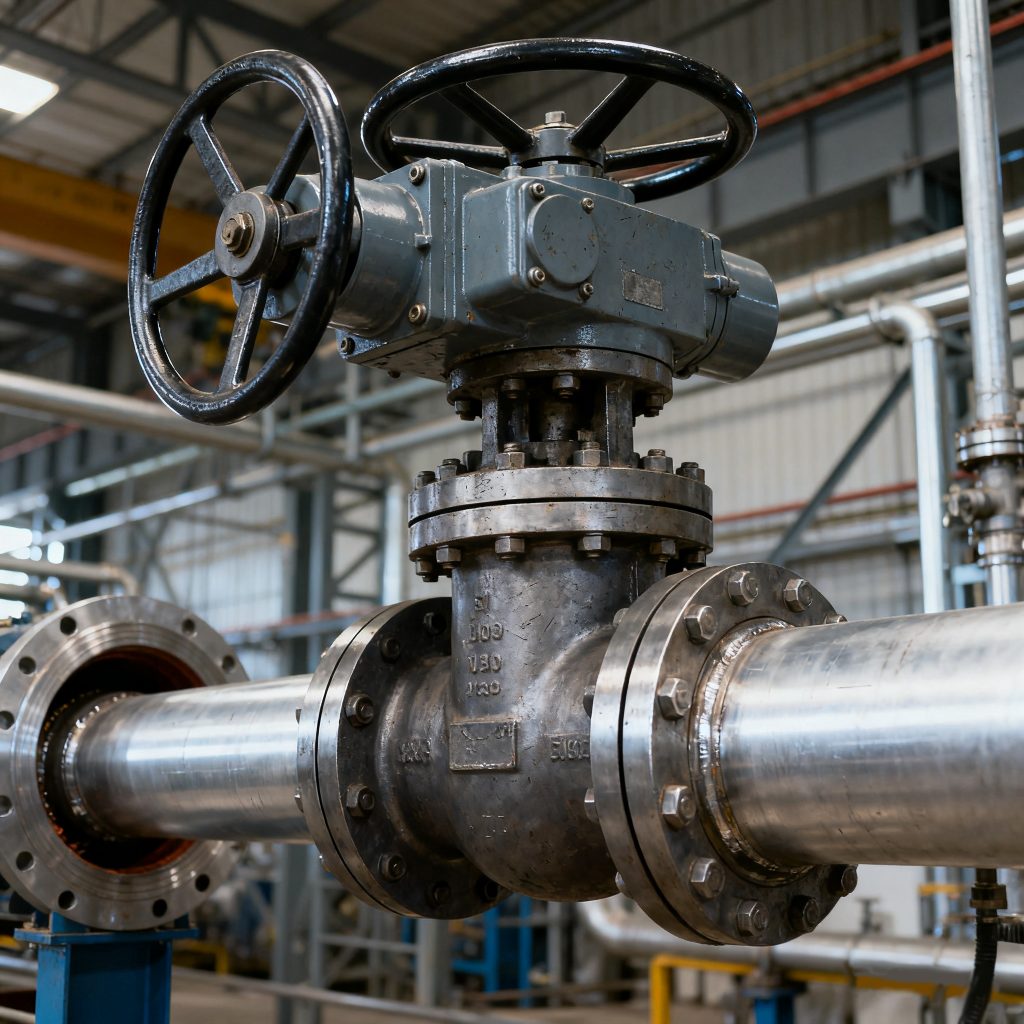

4.Water Treatment Applications

Water treatment facilities use solenoid valves to accurately manage both water flow and chemical dosing.

· Filtration and Distribution: Solenoid shutoff valves regulate water flow through filters and pipelines, ensuring consistent pressure and clean water supply.

· Chemical Dosing: Chemical dosing valves control the injection of disinfectants, pH adjusters, and other treatment chemicals accurately.

· Leak Prevention and Reliability: High-quality valves prevent leaks and downtime, keeping municipal or industrial water systems running smoothly.

Selecting the right water treatment solenoid valve ensures efficiency, safety, and long-term operational reliability.

5.HVAC Applications

HVAC equipment relies on solenoid valves to balance heating, cooling, and air distribution. For more real-world applications, check out Hydronics Hub.

· Refrigerant Control: Refrigerant solenoid valves manage the flow of refrigerants in air conditioning and heat pump systems for precise temperature control.

· Chilled and Hot Water Circuits: Valves for chilled and hot water ensure efficient regulation of heating and cooling systems.

· Energy Efficiency and Automation: Smart HVAC valves integrate with building management systems, optimizing performance while reducing energy consumption.

Choosing the right HVAC solenoid valve ensures reliable operation, precise temperature control, and lower energy costs.

6.Cost, Efficiency, and Maintenance

Selecting the right solenoid valve isn’t just about performance—it also affects cost, efficiency, and maintenance.

· Balancing Price and Quality: Low-cost options can be tempting, but investing in durable solenoid valves usually results in longer service life and fewer failures.

· Energy Efficiency: Using valves designed for optimal flow control minimizes energy consumption and lowers operating costs.

· Maintenance Tips: Regular inspection, cleaning, and checking for leaks or coil wear extend valve lifespan and prevent system failures.

Investing in the right solenoid valve ensures long-term savings, reliable operation, and system efficiency.

Conclusion

Choosing the right solenoid valve is crucial for the performance and reliability of automotive, water treatment, and HVAC systems. Understanding valve types, materials, operating conditions, and industry-specific requirements helps you make informed decisions. Whether it’s a variable valve timing solenoid for precise engine control, a purge solenoid valve for emission management, a chemical dosing valve for water treatment, or a refrigerant solenoid valve for HVAC, selecting the correct valve ensures efficiency, safety, and long-term reliability. Use this guide to identify the right solenoid valve for your system and maximize performance.

About Products

If you’re interested in our products and technology, click here to learn more about how solenoid valves work.