Choosing the right electric actuated valve manufacturer is very important. It affects the safety, efficiency, and reliability of your system. A good and reliable valve supplier makes sure your electric actuated valves work well, reduce downtime, and need less maintenance.

The manufacturer you pick also affects how much you spend in the long run and how smooth your operations will be. Knowing how to check and compare manufacturers helps buyers make better decisions.

1.Understanding Electric Actuated Valves

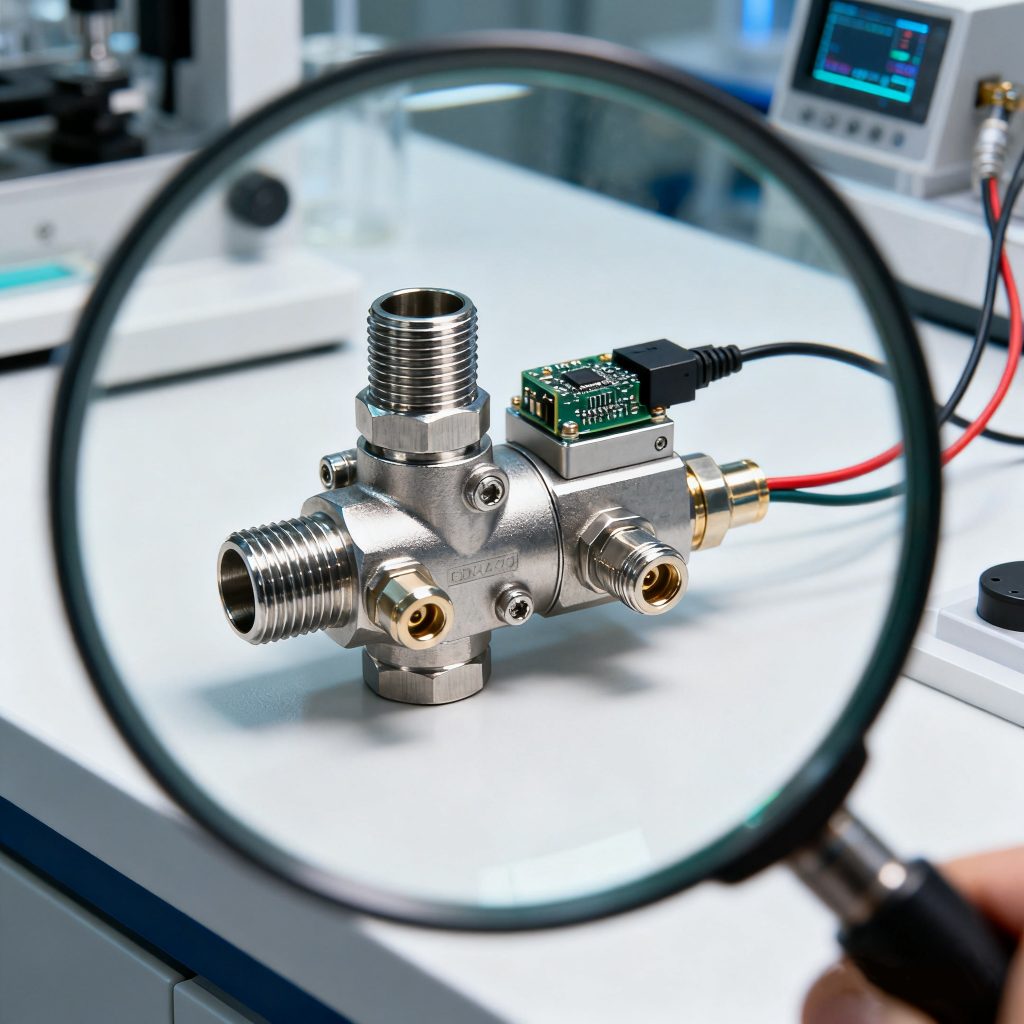

Electric actuated valves use electric motors to open, close, or control the flow of liquids or gases automatically. They are more precise than manual valves and can work with valve automation systems.

These valves are important in industries where accuracy and safety matter. They help reduce human mistakes and make industrial valve systems work more smoothly and reliably.

2.Key Industries Where Electric Actuated Valves Are Used

Electric actuated valves are used in many industries where safety and accuracy are very important.

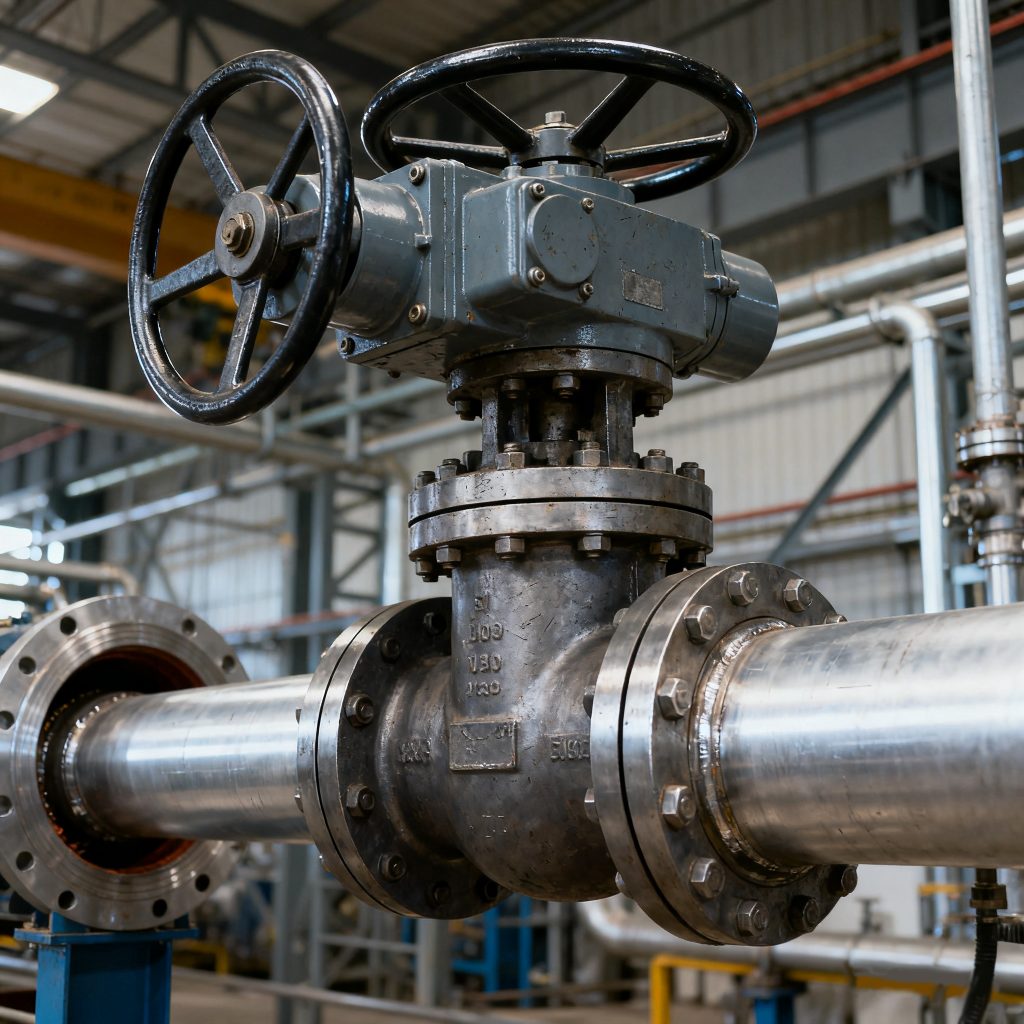

- Oil & Gas: Valves must handle high pressure and dangerous conditions. A trusted manufacturer provides oil and gas electric actuated valves that are safe and reliable.

- Water Treatment: Plants need valves that resist corrosion and last a long time. A good water treatment valve supplier makes sure water flow is steady and downtime is low.

- Food & Beverage: Cleanliness and safety are very important. Working with a food grade electric actuated valve manufacturer gives valves that are easy to clean, safe, and meet FDA and 3-A standards.

- These valves help companies save time, reduce mistakes, and keep systems running efficiently.

3.How Manufacturer Quality Impacts Performance

The quality of an electric actuated valve manufacturer affects how well your system works. A reliable electric valve supplier gives valves that work consistently and keep the system running safely.

Low-quality valves can leak, break, or stop working, which can delay projects and cost more money. High-quality valves last longer, reduce maintenance, and help your system stay reliable.

4.Key Factors to Consider

When choosing an electric actuated valve manufacturer, here are the main things to check:

- Product Quality and Materials: Valves should be strong, resist corrosion, and last a long time. Good materials mean fewer problems and longer use.

- Certifications and Compliance: Check for valve certifications like ISO, CE, and API. These show the valves are safe and accepted worldwide.

- Customization Options: A customized electric actuated valve manufacturer can make valves to fit your special needs, like different size, torque, or materials.

- After-Sales Support: Make sure there is good after-sales valve support, including technical help, spare parts, and service.

- Pricing and Delivery: Think about the total cost of ownership for electric valves, not just the purchase price. Also, check if the manufacturer delivers on time.

5.Questions to Ask a Manufacturer

- Which certifications do your valves meet?

- Can you provide customized solutions for unique industrial processes?

- What after-sales support and spare parts are available?

Conclusion

Selecting the right electric actuated valve manufacturer ensures your electric actuated valves operate safely, efficiently, and reliably. Partnering with a reliable valve supplier guarantees consistent performance, reduces downtime, and maximizes long-term value. By carefully evaluating quality, certifications, customization, and support, procurement teams can ensure smooth operations, cost savings, and successful project outcomes for years to come.

About Products

Want to know more about our electric actuated valve manufacturing expertise and product range? Visit our Electric Actuated Valve page to explore detailed specifications and available options from us.