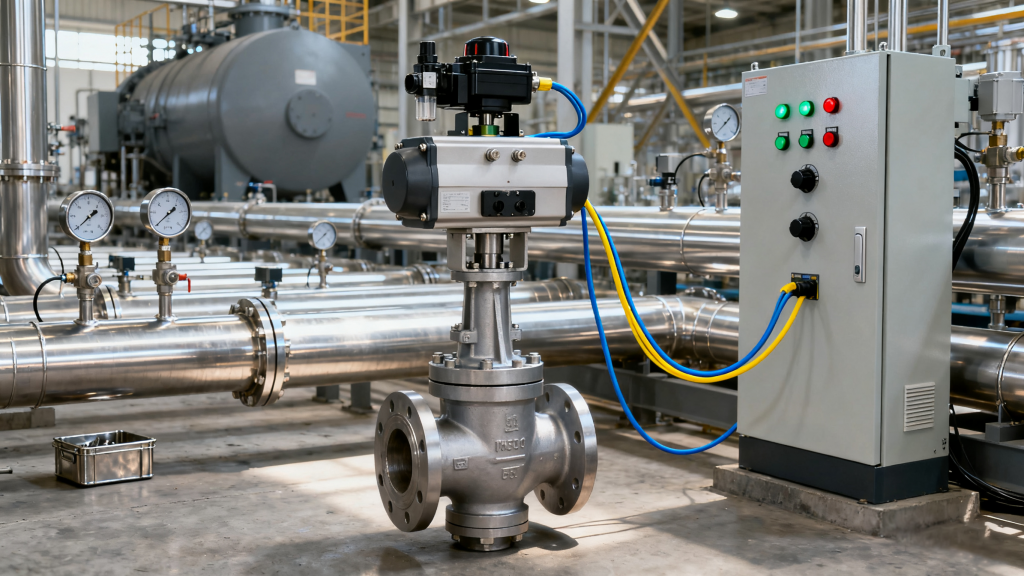

Choosing the right pneumatic actuated valve manufacturer is very important for industrial projects. A reliable manufacturer makes sure valves work well, last longer, and reduce downtime. For buyers, working with affordable pneumatic valve suppliers balances cost and quality. Beyond the products, good after-sales service and custom pneumatic actuator solutions help projects run smoothly and stay successful for a long time.

1.Understanding Pneumatic Actuated Valves Suppliers

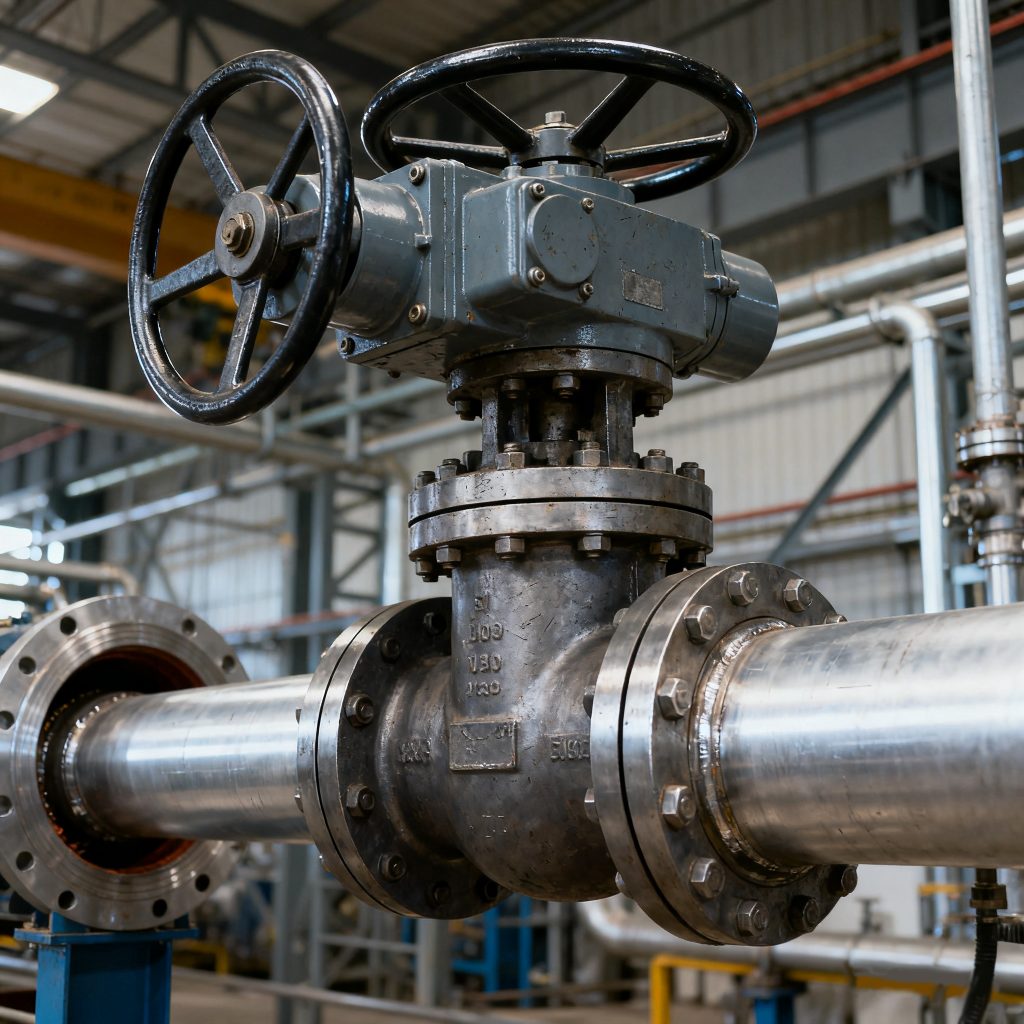

Pneumatic actuated valves use compressed air to control the flow of liquids or gases. Industries use them widely because they control liquids and gases quickly, safely, and accurately. There are several common types of valves. These include quarter-turn valves, linear valves, and multi-turn valves. Each type is designed for different industrial tasks.

Working with reliable pneumatic valve manufacturers helps operations run more smoothly. It also reduces the need for repairs and improves efficiency. These valves are often used in industries like oil and gas, water treatment, chemical plants, and food and beverage production.

2.Certifications and Compliance

Certifications like ISO, CE, and ATEX show that valves meet strict international standards. In some industries, such as food and chemicals, following hygiene and safety rules is critical. Choosing certified reliable pneumatic valve manufacturers ensures systems operate safely, efficiently, and within regulations.

3.Product Quality and Reliability

Quality is very important. High-quality valves use strong, corrosion-resistant materials that last longer and work well under tough conditions. Many affordable pneumatic valve suppliers also test for pressure, leaks, and cycles to make sure the valves are reliable. Good quality control reduces repair costs, lowers the chance of breakdowns, and keeps operations running smoothly.

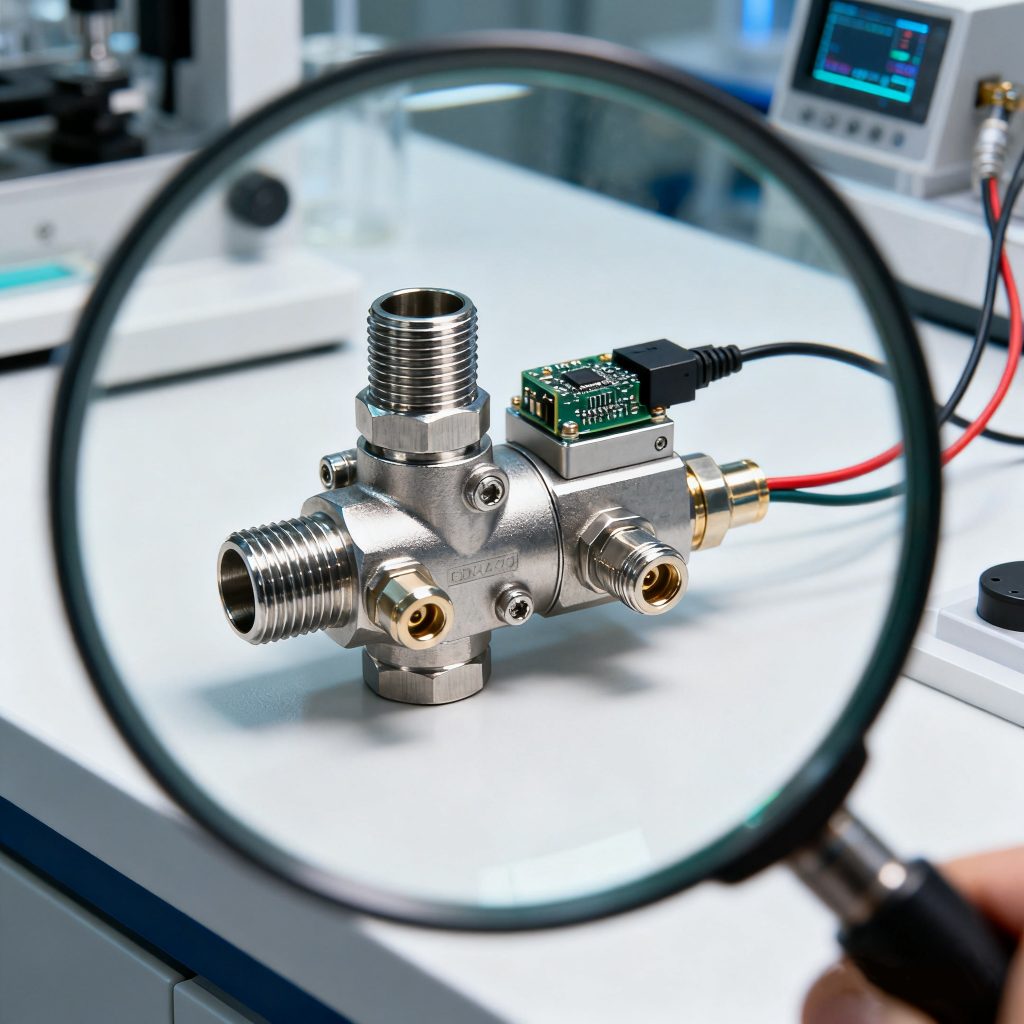

4.Customization and Technical Support

Every project has unique needs. Manufacturers offering custom pneumatic actuator solutions can design valves for specific pressures, flow rates, or environments. Strong technical support is also important. Reliable pneumatic valve manufacturers help with installation, troubleshooting, training, and manuals. Combining customization with expertise makes projects run smoother and ensures long-term reliability.

5.Production Capacity and Delivery

Timely delivery is key. Manufacturers with strong production capabilities can handle both small and large orders without delays. Working with reliable pneumatic valve manufacturers who provide clear delivery timelines and logistics helps avoid project delays and costly downtime.

6.After-Sales Service and Maintenance

Good after-sales service supports long-term operations. Services like warranties, repairs, and preventive maintenance programs keep valves working properly. Affordable pneumatic valve suppliers who offer dedicated technical assistance help solve problems quickly, extend valve life, and maintain stable industrial operations.

7.Customer Reputation and Case Studies

Checking a manufacturer’s reputation is important. Reviews, testimonials, and client feedback show how reliable a supplier is. Case studies demonstrate how custom pneumatic actuator solutions worked in real projects. This helps buyers anticipate challenges and build confidence in their choice.

8.Cost and Value

Price is important, but long-term value matters more. Reliable pneumatic valve manufacturers may cost more upfront, but high quality reduces maintenance and breakdowns. Investing in custom solutions ensures valves meet project needs exactly, preventing future costs. Balancing cost, quality, and support leads to smarter purchasing decisions.

Conclusion

Choosing the right pneumatic actuated valve manufacturer affects efficiency, reliability, and long-term success. Evaluating certifications, product quality, customization, delivery, and reputation reduces risks.

Working with reliable pneumatic valve manufacturers and affordable pneumatic valve suppliers who offer custom pneumatic actuator solutions ensures valves operate efficiently, maintenance is easier, and downtime is minimized. Careful research and comparison lead to smoother operations, cost savings, and confidence in industrial projects.

About Products

As a professional pneumatic actuated valve manufacturer, we are committed to providing reliable, efficient, and customized valve solutions for various industries. Visit our product page Pneumatic Actuated Valve product page to learn more or contact us for tailored support.