Selecting the right globe control valve is crucial for industrial systems. It ensures safe and efficient flow of liquids and gases. Partnering with a reliable manufacturer or supplier improves performance and reliability. Models vary for different applications, such as pressure regulation or temperature control.

1.Understanding Globe Control Valves: Function and Types

Globe control valves in industrial systems

- Widely used to manage the flow of liquids and gases.

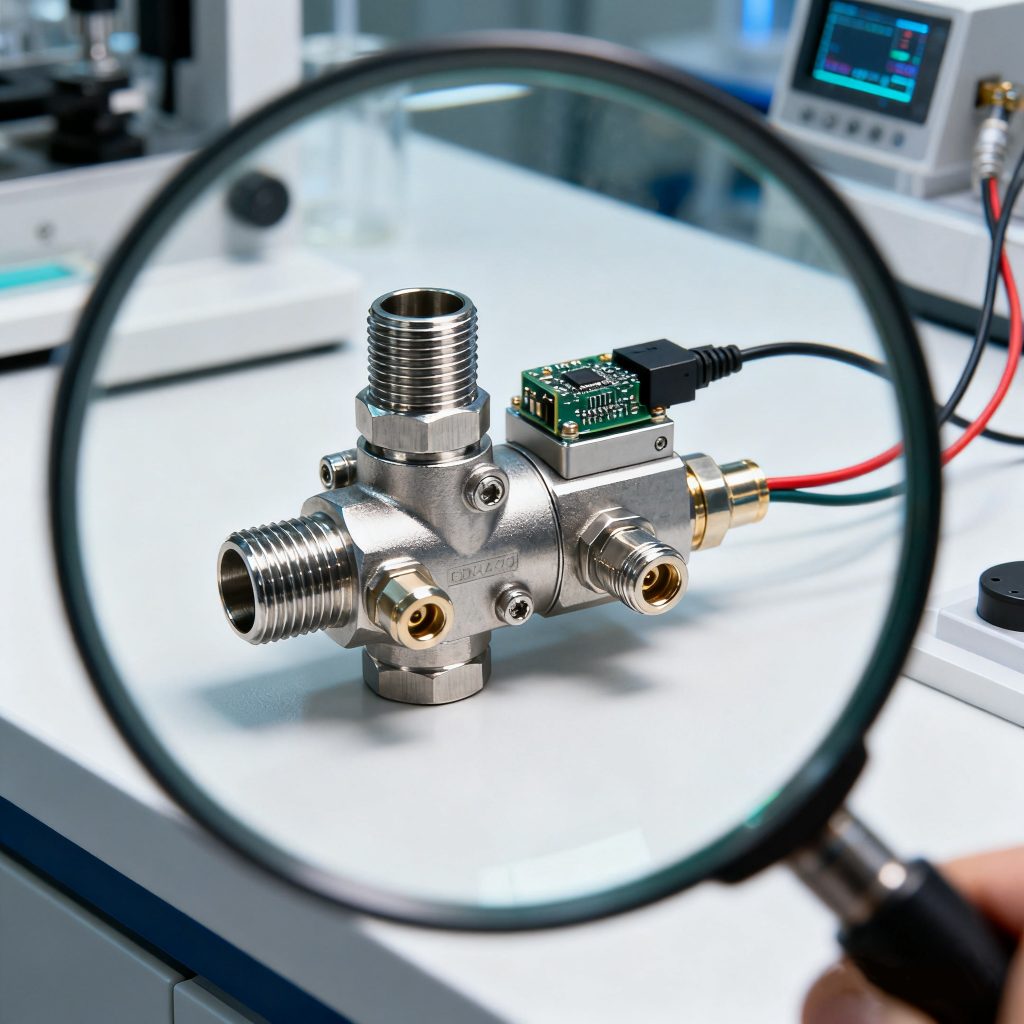

- Work by adjusting a movable plug inside the valve body to regulate flow precisely.

Common types of globe valves

- Linear valves: Best for precise flow control.

- Angle valves: Handle directional changes in pipelines.

- Three-way valves: Allow mixing or diverting of flow.

Tip

- Consulting a trusted globe control valve manufacturer or supplier helps you choose the right type for your system.

2.Assessing Your System Requirements

Before selecting a globe control valve, assess system needs like flow rate, pressure drop, operating temperature, and fluid type.

Accurate control is vital for safety and efficiency. A reliable supplier can help evaluate these factors and recommend the right valve for long-term performance.

3.Material and Actuation Selection

Choosing the right material and actuator is essential for the durability and performance of a globe control valve. Both factors directly affect efficiency, safety, and long-term reliability.

- Material matters:

- Common options include stainless steel, cast iron, and bronze.

- The chosen material must resist corrosion, wear, and chemical reactions, depending on the system’s fluid type.

- Actuator options:

- Manual valves are simple and cost-effective.

- Pneumatic actuators offer fast and reliable control.

- Electric actuators provide precise and automated operation.

Partnering with a reliable globe valve supplier or industrial valve manufacturer helps you select the best combination of material and actuator, ensuring your system runs smoothly and efficiently.

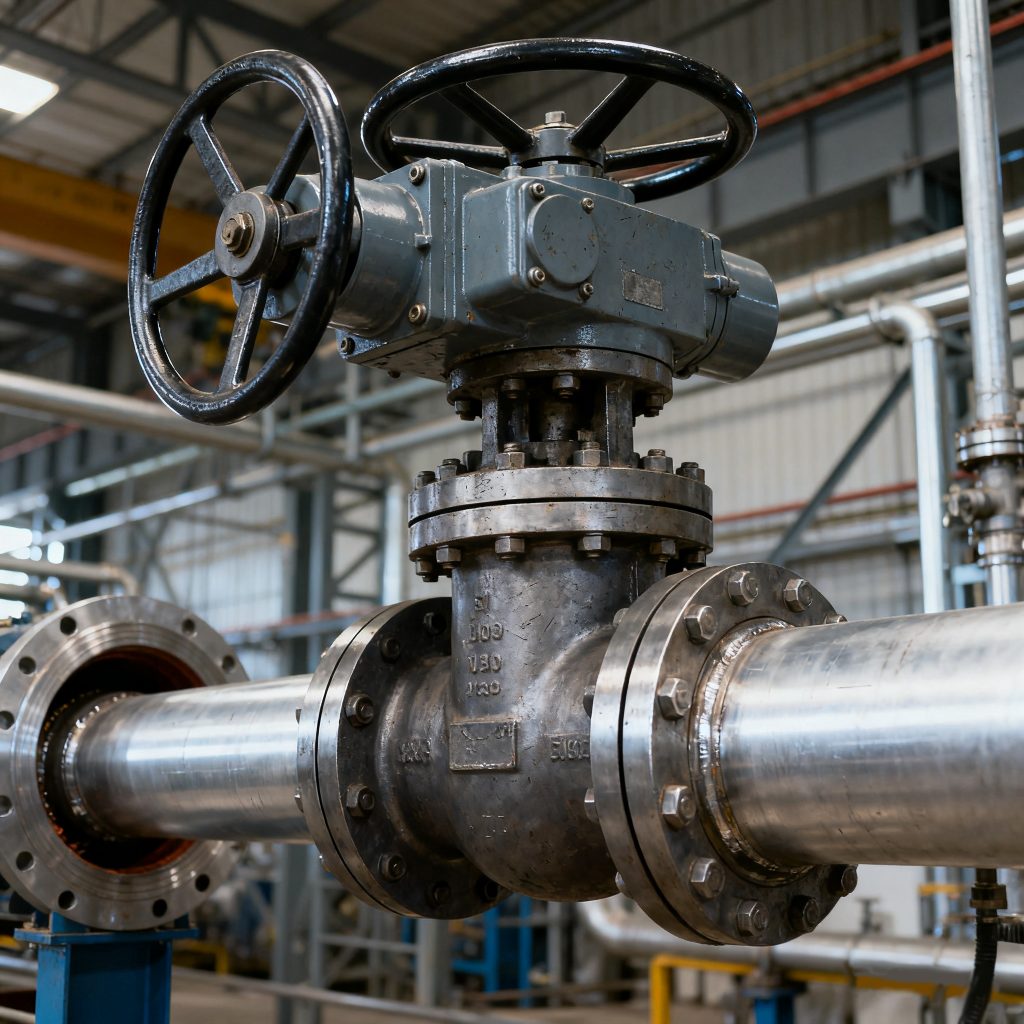

4.Valve Sizing and Installation Essentials

Proper sizing and correct installation are vital to ensure a globe control valve performs efficiently and reliably within an industrial system.

- Flow capacity:

- The flow coefficient (Cv) determines if the valve can handle the required flow without creating excessive pressure drop.

- Connection types:

- Flanged connections provide strength and allow easy removal.

- Threaded connections are suited for smaller systems.

- Welded connections create a permanent, leak-tight setup.

- Additional considerations:

- Pressure and temperature ratings

- Leakage class

- Flow characteristics

Partnering with a trusted globe control valve manufacturer or globe valve supplier helps simplify the sizing and installation process, ensuring long-term efficiency and reliable operation.

5.Evaluating Suppliers and Technical Support

Choosing the right globe valve supplier or industrial valve manufacturer is just as important as selecting the valve itself. Experienced suppliers provide guidance on valve selection, installation, and maintenance, helping you avoid costly mistakes. Look for manufacturers with certifications such as ISO, CE, or API to ensure product quality and safety.

A good supplier also offers customization options and reliable technical support to meet unique system needs. Partnering with a trusted globe control valve manufacturer keeps your system efficient and reduces the risk of downtime.

6.Balancing Cost and Real-World Performance

When selecting a globe control valve, consider both cost and long-term performance. Cheaper valves may seem attractive but can lead to higher maintenance over time. Evaluating total cost of ownership—including installation, operation, and maintenance—helps make a more informed decision. Customer reviews and case studies from trusted globe valve suppliers provide insights on which valves perform reliably under demanding conditions.

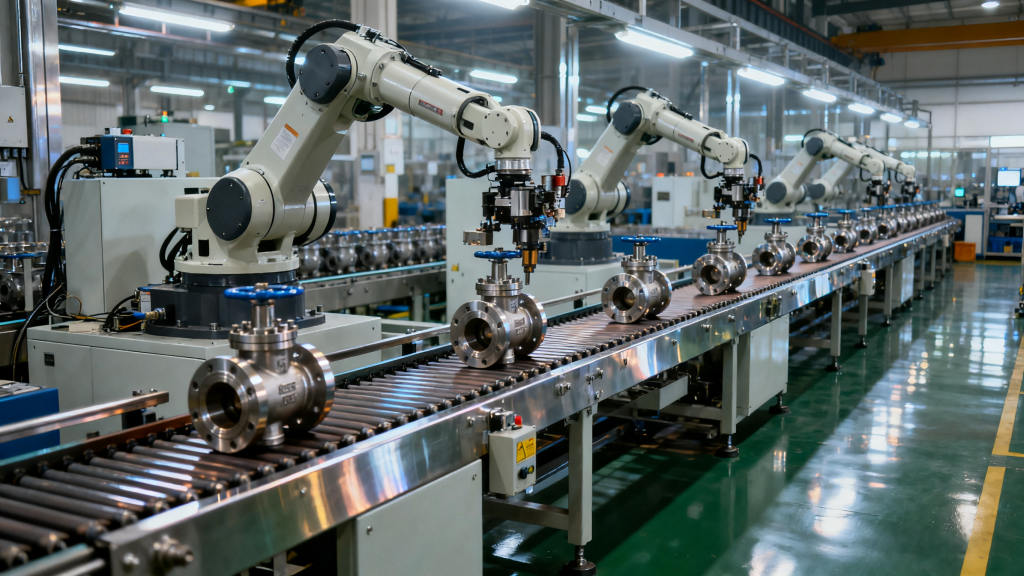

7.Innovation and Building Long-Term Partnerships

Modern globe control valve manufacturers invest in research and development to improve valve efficiency, durability, and control accuracy. Advanced designs, such as high-performance trims and improved sealing technology, help industrial systems operate more reliably. Establishing a long-term partnership with a trusted globe valve supplier allows you to access ongoing technical support, updates on new products, and customized solutions. Such collaboration ensures your industrial system stays efficient, safe, and adaptable to future needs.

Conclusion

Selecting the best globe control valve requires considering system needs, materials, actuation, sizing, and supplier expertise. Working with a reputable globe control valve manufacturer or globe valve supplier ensures high-quality valves. Balancing cost, performance, and long-term support improves efficiency, reduces maintenance, and prevents downtime, ensuring safe and reliable industrial operations.