Electric ball valves play a crucial role in modern industrial and commercial systems. Choosing the right electric ball valve ensures system efficiency, prevents leaks, and reduces maintenance costs. Many users struggle to pick the right type, whether it’s a motorized valve, a stainless steel electric ball valve, or one designed for remote control. This guide will help you understand the key factors in selecting an actuated valve that meets your system’s needs.

1.Understanding Electric Ball Valves and Their Benefits

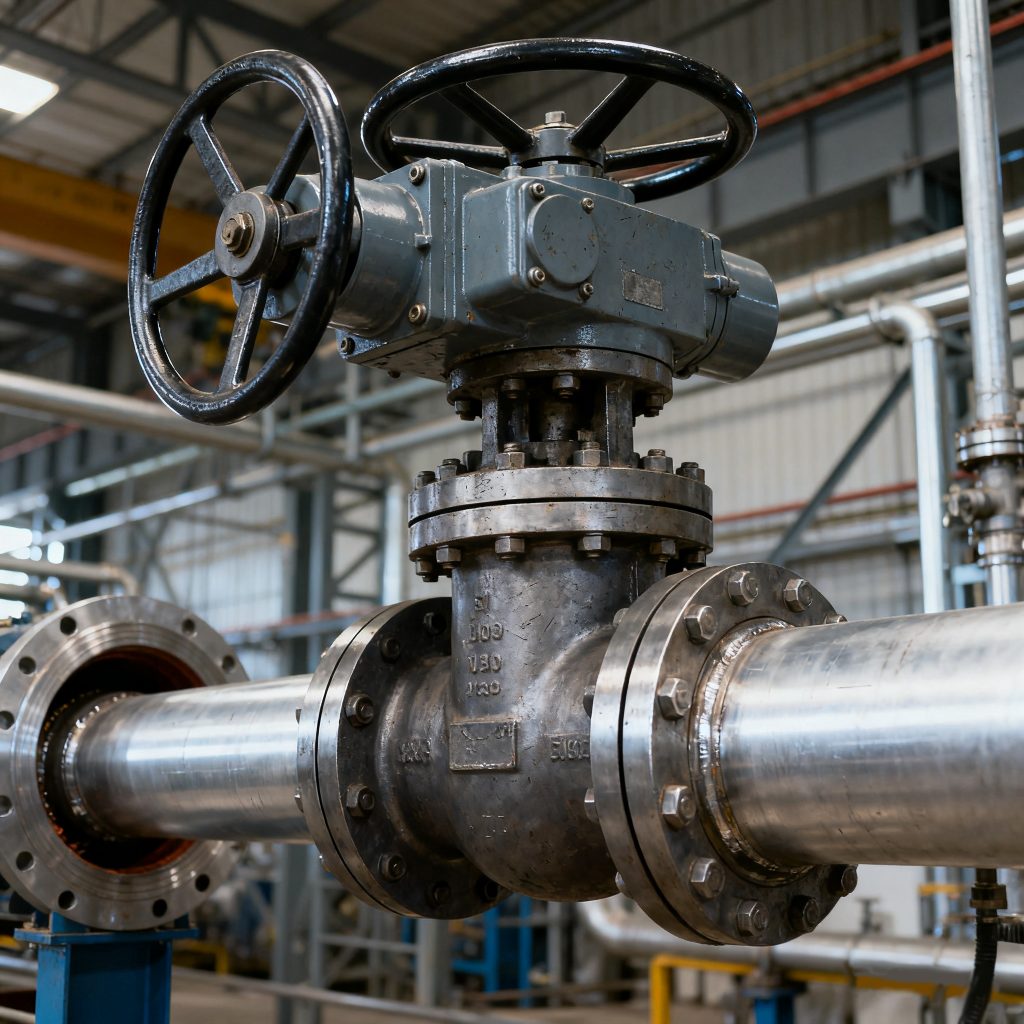

Electric valves are essential components in modern fluid control systems. They combine the reliability of traditional control valves with the precision and automation provided by electric actuators. These valves are widely used in industries such as HVAC systems, water treatment plants, and industrial automation.

How Electric Ball Valves Work

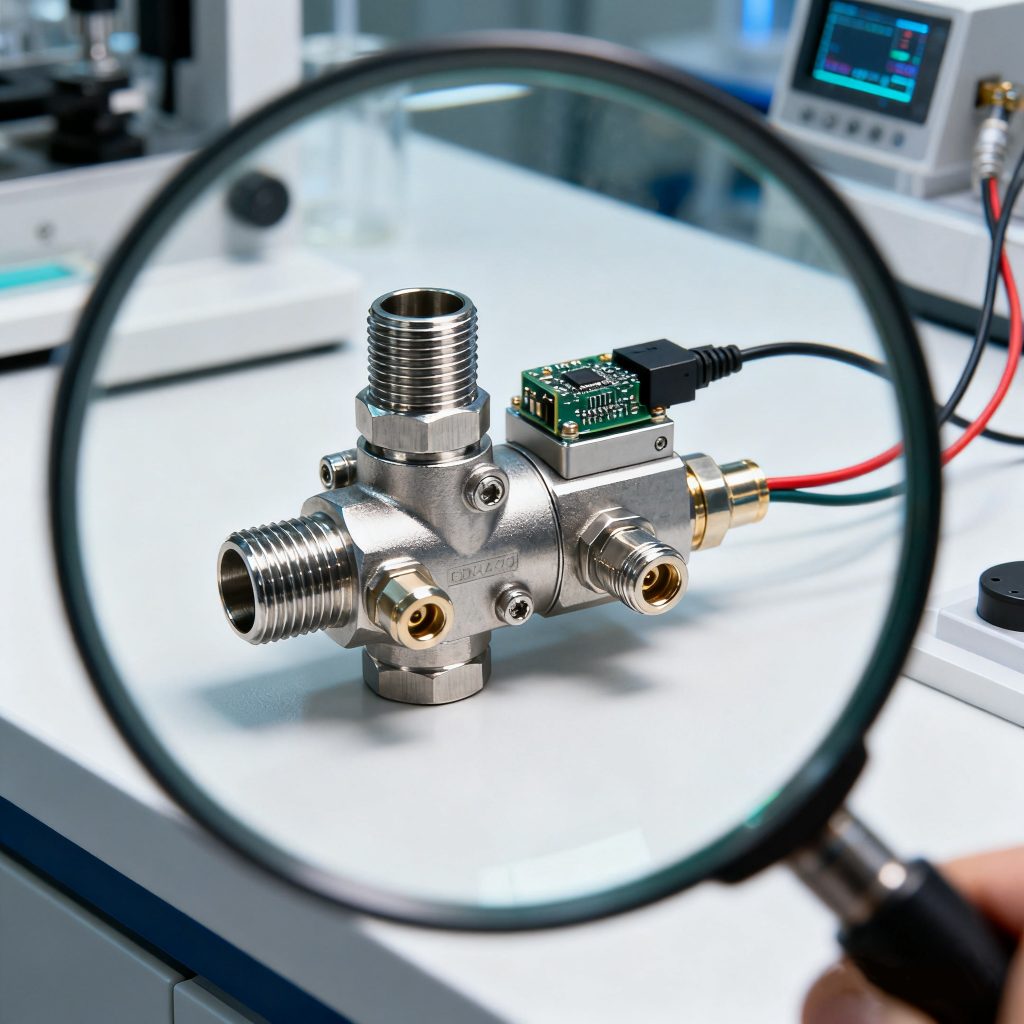

An actuated valve consists of two main parts: the valve body and the electric actuator. The valve controls the flow of fluid through a rotating mechanism, while the actuator moves it to open or close the flow. This setup allows for precise control and remote operation, making it ideal for automated systems.

Key Benefits

- Automated Control: Electric valves, including motorized valves, can be integrated into automated systems for remote operation and monitoring. This is especially useful in large-scale operations where manual control would be inefficient.

- Precision and Reliability: With accurate control of valve position, actuated valves provide consistent flow rates and minimize human error, ensuring system reliability.

- Versatility: Available in various materials such as stainless steel and plastic, electric valves can handle applications from water distribution to corrosive chemical processes.

- Energy Efficiency: Unlike solenoid valves that need continuous power, electric and motorized valves consume energy only during operation, saving power and reducing costs.

For more details on electric valves, see Valworx Electric Actuated Stainless Valves and US Solid Motorized Valves.

2.Core Selection Factors

When selecting an electric ball valve for your system, several factors determine efficiency, safety, and longevity. Knowing these factors helps choose the right type—whether it’s a motorized valve, a stainless steel actuated valve, or a remotely controlled version.

-

Connection Methods and Standards

Connection types include flanged, threaded, welded, and clamp/quick-install. Matching pipeline standards such as ANSI, DIN, JIS, or GB is essential to prevent installation problems and ensure smooth operation.

-

Body Materials

Materials range from stainless steel, carbon steel, duplex steel, to plastics. The choice depends on the medium, environmental conditions, and corrosion resistance. Stainless steel electric valves are preferred in chemical and water applications for durability.

-

Pressure, Temperature, and Sizing

The valve must handle the system’s maximum pressure and temperature with safety margins. Proper sizing ensures efficient flow, avoids energy loss, and prevents erosion from high velocity or turbulence.

-

Electric Actuator Considerations

Consider power supply type (AC or DC), control mode (on/off or modulating), torque, speed, and IP rating. Environmental factors, such as explosion-proof requirements, humidity, or dust, also affect long-term performance.

-

System Integration

Motorized and actuated valves can be integrated with automation systems for centralized or remote control, enabling intelligent operation. This improves operational efficiency and reduces manual intervention.

Special Applications and Common Pitfalls

Electric valves are versatile, but certain environments need special attention. In hazardous, corrosive, or hygienic systems, choosing the right material and actuator is critical. Stainless steel actuated valves are preferred in chemical and food processing applications, while explosion-proof motorized valves are essential in flammable environments.

Common mistakes include selecting based only on price, ignoring standards, or mismatched actuator specs. These issues can lead to leaks, inefficiency, or safety hazards. To avoid problems, assess system requirements, consult suppliers, and review technical datasheets. Planning regular maintenance extends valve lifespan.

For more industrial actuator options, check Flow Actuated Valves or ALSCO Plastics Actuated Valves.

Conclusion

The right and suitabe electric ball valve selection is not just technical—it impacts efficiency, safety, and reliability. By considering connection methods, materials, pressure and temperature ratings, sizing, actuator specs, and system integration, you ensure long-term performance and minimal maintenance. Whether it’s a motorized valve for automation, a stainless steel actuated valve for chemical use, or a remotely controlled electric valve, these guidelines will help you make the best choice.

Always consult valve experts or trusted suppliers when in doubt. Expert guidance ensures compatibility, optimal performance, and safety, giving you confidence in your system’s long-term operation.

About Products

Feeling curious? Explore our range of Electric Ball Valves for more details.