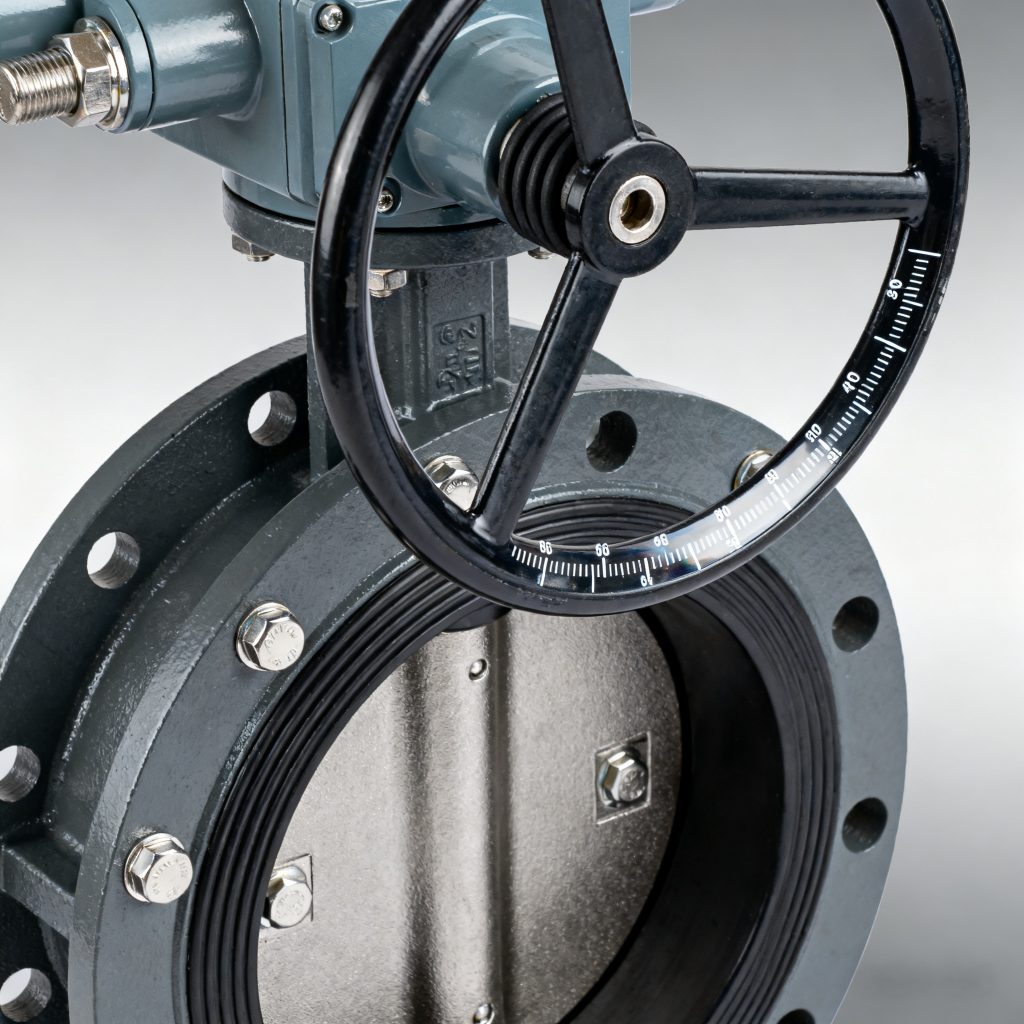

Choosing the right electric butterfly valve is essential for safe and efficient flow control. These valves are popular because of their low cost, lightweight construction, and ability to handle large diameter pipelines with high flow rates.

Because these butterfly valves have a compact design and can open or close quickly with just a quarter turn, people use them a lot in water systems, HVAC, and factories where keeping the valve in the right position and controlling it automatically is important.

1.What is an Electric Butterfly Valve?

An electric butterfly valve is a flow control device driven by an electric actuator. It uses a rotating disc to regulate liquid or gas, typically with a quarter turn. The actuator allows automatic operation, clear valve position feedback, and integration with limit switches for better system control. Unlike other valve types, butterfly valves offer a cost-effective solution for large flow systems due to their simple, lightweight design.

2.Valve Connection Types

- Wafer Style

- Offers a compact design that saves space and reduces cost.

- Flanged Type

- Provides strong sealing for high-pressure pipelines.

- Lug Type

- Allows easier installation and removal, especially when parts of the system need maintenance without shutting down the whole pipeline.

- Lightweight Structure

- Suitable for large-diameter pipelines where heavy valves would be cumbersome and expensive.

3.Industry Standards and Compatibility

When selecting an electric actuated butterfly valve, it is important to check pipeline standards. Common options include ANSI in North America, DIN in Europe, JIS in Japan, and GB in China. Picking the right standard makes installation easier, keeps the valve in the correct position, and lets it work well with other electric actuated butterfly valves or system parts. Standard compliance also supports long-term reliability and reduces maintenance issues.

4.Choosing the Right Valve Body Material

The body material of a butterfly valve affects durability, weight, and cost. Stainless steel works best in places where things can corrode, and carbon steel is strong but cheaper, so it’s good for most industrial uses. People often pick lightweight plastics like UPVC or CPVC for chemical systems because they are compact, resist corrosion, and cost less. For large pipelines, using a lightweight material reduces installation effort and helps maintain precise valve position.

5.Disc and Seal Options

- Disc Materials

- Stainless steel or duplex steel discs provide durability for demanding applications.

- Aluminum bronze discs are preferred in marine systems.

- Seal Materials

- EPDM works well with water.

- NBR is suited for oils.

- PTFE offers excellent resistance against chemicals and high temperatures.

- Cost and Application Benefits

- The choice of disc and seal materials influences overall cost.

- Proper selection allows butterfly valves to remain an economical option for large-scale operations.

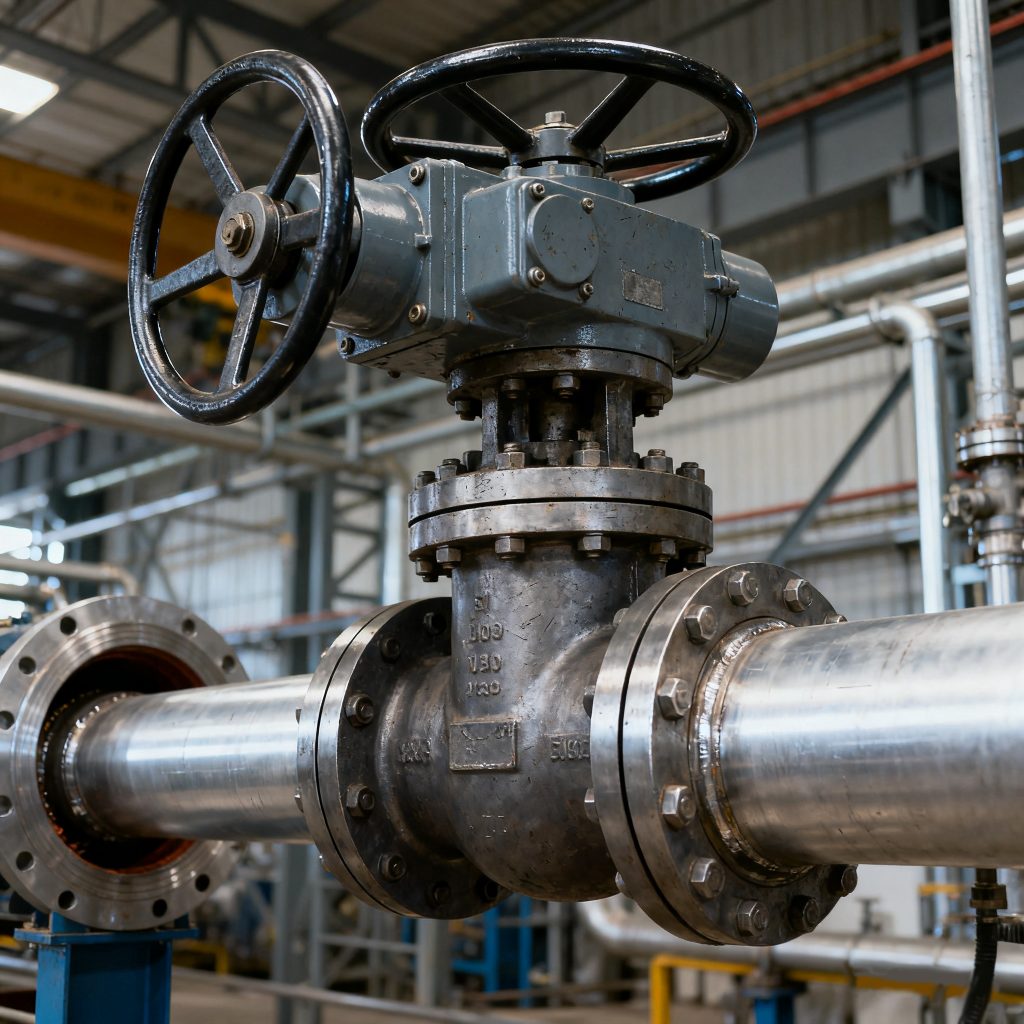

6.Pressure and Temperature Considerations

Every butterfly valve must match the system’s working pressure and temperature. Using a valve with a lower pressure rating can cause leaks or damage. High or fluctuating temperatures may weaken seals or affect valve position accuracy.

Selecting materials and designs that fit operating conditions ensures long-term reliability. Electric actuated designs can also provide consistent control even under varying temperature and pressure, making them suitable for large water or process systems.

7.Valve Sizing for Accurate Flow Control

Correct sizing is essential for an electric actuated butterfly valve. Oversized valves may reduce efficiency and waste energy, while undersized valves restrict flow and strain the actuator. Choosing a valve size that fits the pipeline keeps the flow steady, the valve in the right position, and the system working reliably. Butterfly valves can handle large pipes easily, making them perfect for high-flow systems without needing heavy or expensive valves.

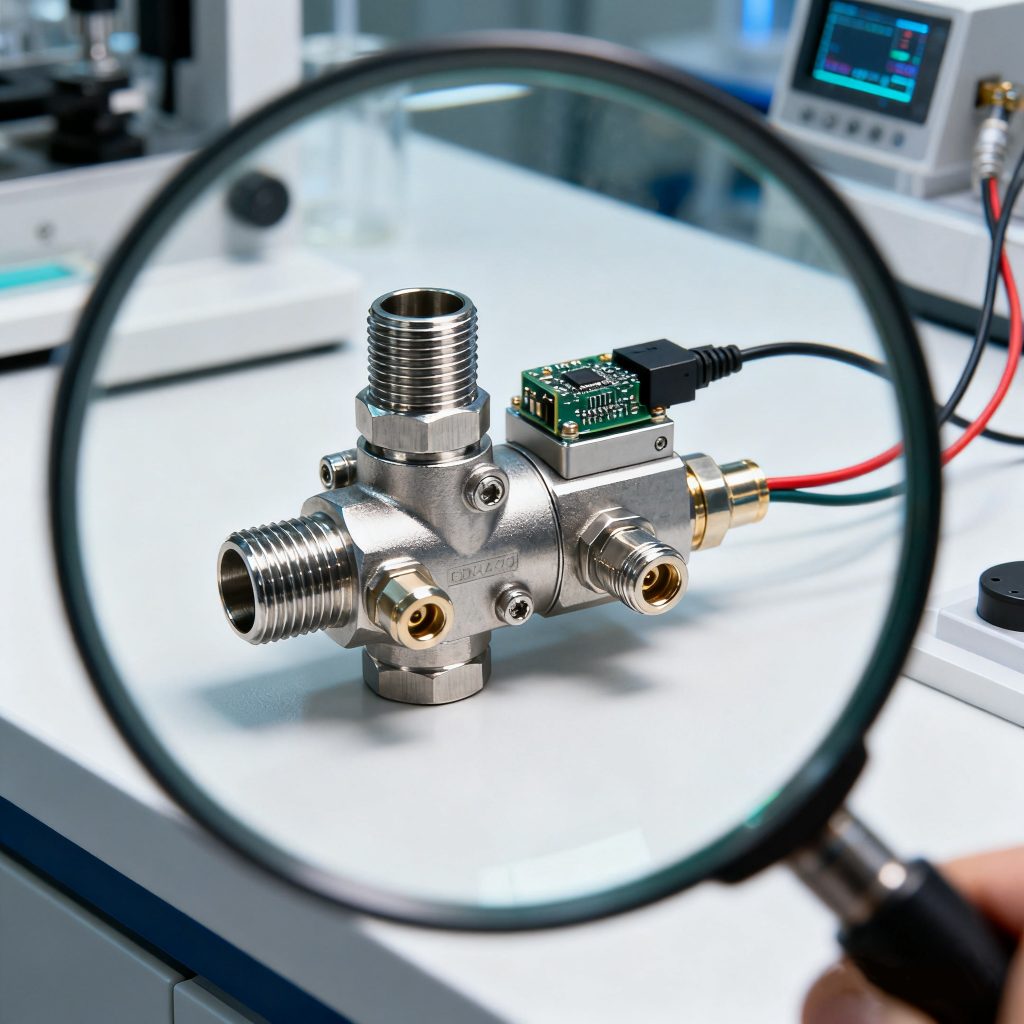

8.Electric Actuator Essentials

The electric actuator controls the butterfly valve automatically. It can be AC or DC powered and operate in On/Off or modulating modes. Proper torque ensures smooth quarter turn operation, while limit switches provide accurate valve position feedback.

Choosing the right actuator type is key to system reliability and efficiency. Automated control lets operators open or close the valves from a distance, which is very helpful for big pipelines or systems with many electric actuated butterfly valves.

9.Smart Features and Automation

Modern electric actuated butterfly valves often include smart features. Remote monitoring allows operators to check valve position and performance in real time. Integration with control systems improves automation, while energy-efficient designs reduce operating costs.

Some models even allow automatic adjustment for varying flow rates, maintaining precise valve position without manual intervention. These features help maintain system stability and quick response to changes, enhancing efficiency in large-scale water and industrial applications.

10.Installation and Maintenance

Proper installation ensures long-term valve performance. Align the valve carefully with the pipeline and secure all connections. Regular maintenance, such as checking seals, actuators, and limit switches, helps prevent leaks and ensures accurate valve position.

Lightweight valves are easier to install, even in large-diameter pipelines, reducing labor costs and installation time. Well-maintained valves extend service life and reduce downtime.

11.Applications Across Industries

Electric actuated butterfly valves are used in water treatment, HVAC, chemical processing, and oil & gas systems. Their compact design fits tight spaces, and accurate quarter turn operation ensures precise valve position. Large-diameter versions handle high flow volumes efficiently. Some models, like those from Valworx or Belimo, integrate limit switches for automated monitoring, while maintaining lightweight construction for easy installation.

12.Compliance and Certification

Choosing valves with proper certifications ensures safety and reliability. Look for ISO, CE, or API compliance. Certified electric actuated butterfly valves follow industry rules, keep the valve in the right position, and are checked for pressure and temperature limits, giving operators confidence that they will work safely in industrial systems. Certified lightweight designs also support safe handling in large-diameter pipelines.

13.Balancing Cost and Long-Term Value

When selecting an electric actuated butterfly valve, consider both upfront cost and long-term performance. Cheaper valves may save money initially but can lead to maintenance issues or shorter service life. Investing in quality valves with durable materials, precise actuators, and lightweight designs ensures reliable operation, easier installation, and lower overall costs, especially for large systems.

Conclusion

To pick the right electric actuated butterfly valve, you need to think about the connection type, the materials of the body and disc, the pressure and temperature, the valve size, and the actuator features.

By looking at all these factors and choosing valves that are smart, lightweight, can handle large pipes, and have proper certifications, you make sure the valve works reliably, stays in the right position, and keeps your system running smoothly for a long time.

About Products

If you are looking for a reliable electric butterfly valve product that fits your needs, explore our Electric Butterfly Valves solutions.