Electric Gate and Knife Gate Valves

Providing reliable full open/close isolation with high-pressure sealing integrity for demanding industrial pipelines.

Why Choose Electric Gate and Knife Gate Valves for High-Pressure, High-Temperature Pipelines?

Electric gate valves and electric knife gate valves deliver tight, dependable shut-off and are built to handle high-pressure and high-temperature service. As full-open/full-close isolation valves, both designs provide low flow friction, strong sealing integrity and long service life.

Known for rapid isolation and reliable sealing performance, electric knife gate valves excel in handling solids, slurry, sludge and fibrous media—while electric gate valves maintain stable shut-off in demanding fluid systems. Together, they serve as preferred solutions for petrochemical pipelines, power plants, water utilities and other heavy-duty applications requiring secure and consistent pipeline control and isolation.

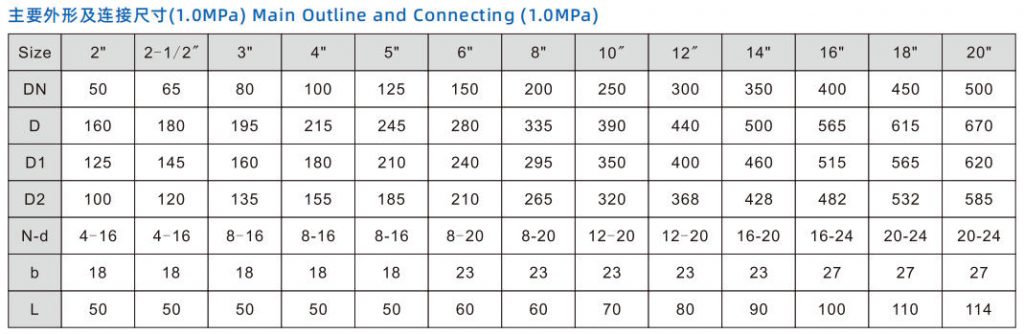

Electric Gate Valves Series

Electric Actuated Flanged Gate Valves

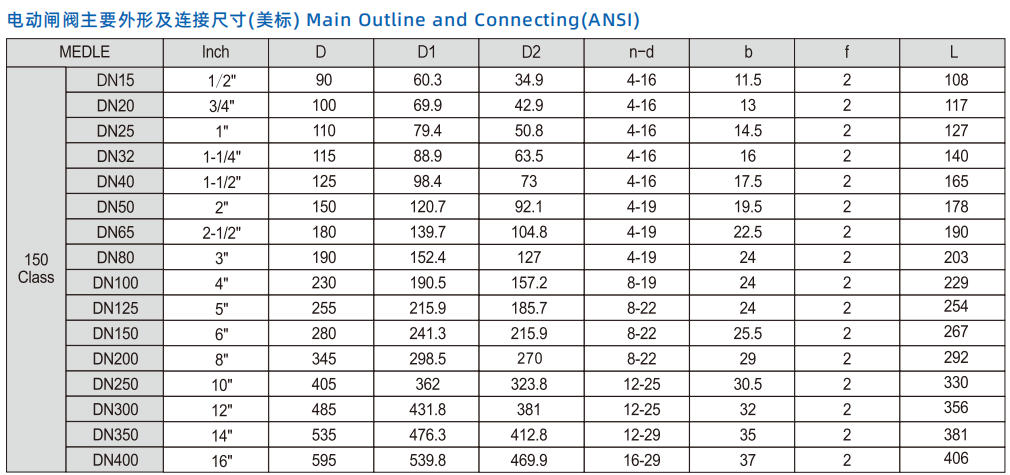

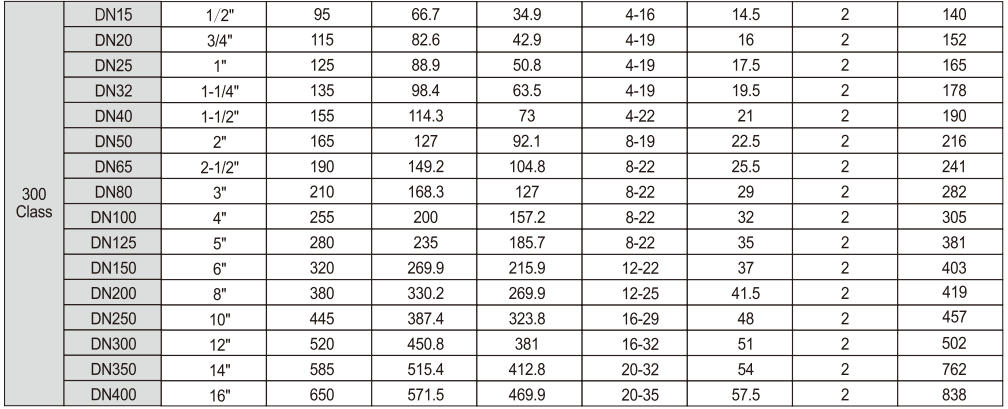

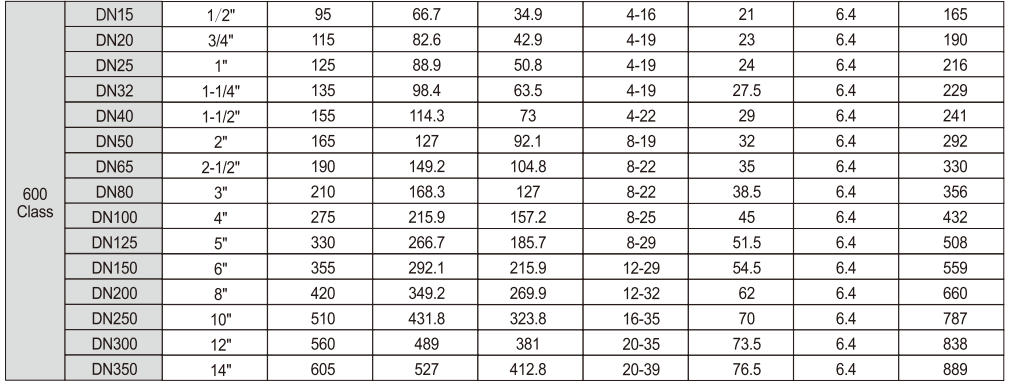

- Size range: DN15 to DN300

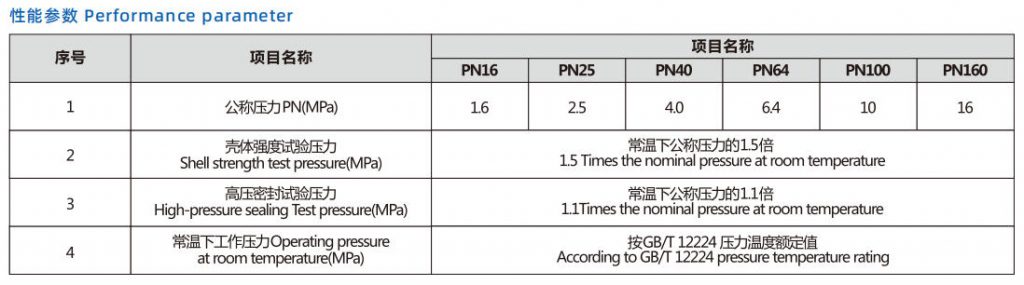

- Working pressure range: 10/16/25/40/64bar

- Working temperature range: -10 to 300℃

- Valve materials: CF8, CF8M, WCB

- Connection: Flanged (ANSI, JIS, DIN, GB)

- Application: Water, steam and so on

Electric Explosion-proof Gate Valves

- Size range: DN50-DN400

- Working pressure range: 1.0 to 6.4MPa

- Working temperature range: -20 ~ + 60 ℃

- Valve materials: Stainless Steel

- Connection: Flange & Butt welding

- Application: Water, Air, Gas, Petroleum, Oil

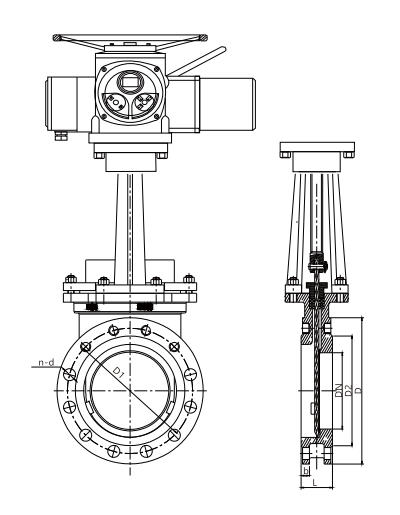

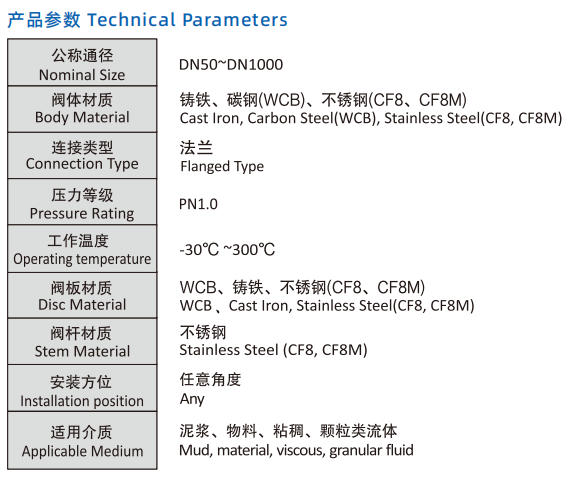

Electric Knife Gate Valves Series

Electric Actuated Knife Gate Valves

- Size range: DN15 to DN300

- Working pressure range: 10/16bar

- Working temperature range: -10 to 300℃

- Valve materials: CF8, CF8M, WCB

- Connection: Flanged/Lugged/Wafer

- Application: Pulp, slurry and so on

Which Industries Commonly Use Gate Valves and Knife Gate Valves?

In the main transmission pipeline of the petrochemical industry, the electric gate valve plays a crucial role in:

Remote Flow Control: Electric gate valves enable remote control of pipeline flow, ensuring efficient and precise fluid transport.

Remote Open/Close Control: They allow for safe, remote operation of valve opening and closing.

Remote Seal Monitoring: The valves continuously monitor their seal reliability, preventing leaks and ensuring system integrity.

This setup enhances system safety, reliability, and automation in petrochemical operations.

In the power and energy sector, the electric gate valve:

- Controls cooling water and steam flow for stable system operation.

- Handles high temperature and pressure with reliable performance.

- Supports remote and automated control through electric actuators.

- Ensures pipeline safety with strong, leak-tight sealing.

This combination ensures safe and efficient pipeline management in power plants.

Electric gate valves in water treatment systems enable automated control of wastewater and clean water in main supply pipelines.

Automated flow control for both wastewater and clean water.

Electric actuator integration for precise and remote operation.

Strong pressure resistance for stable system performance.

Reliable sealing to prevent leaks and ensure system safety.

Together, these features ensure efficient and safe pipeline operation in water treatment processes.

Other Relational Information

Electric Gate Valves

Electric Knife Gate Valves