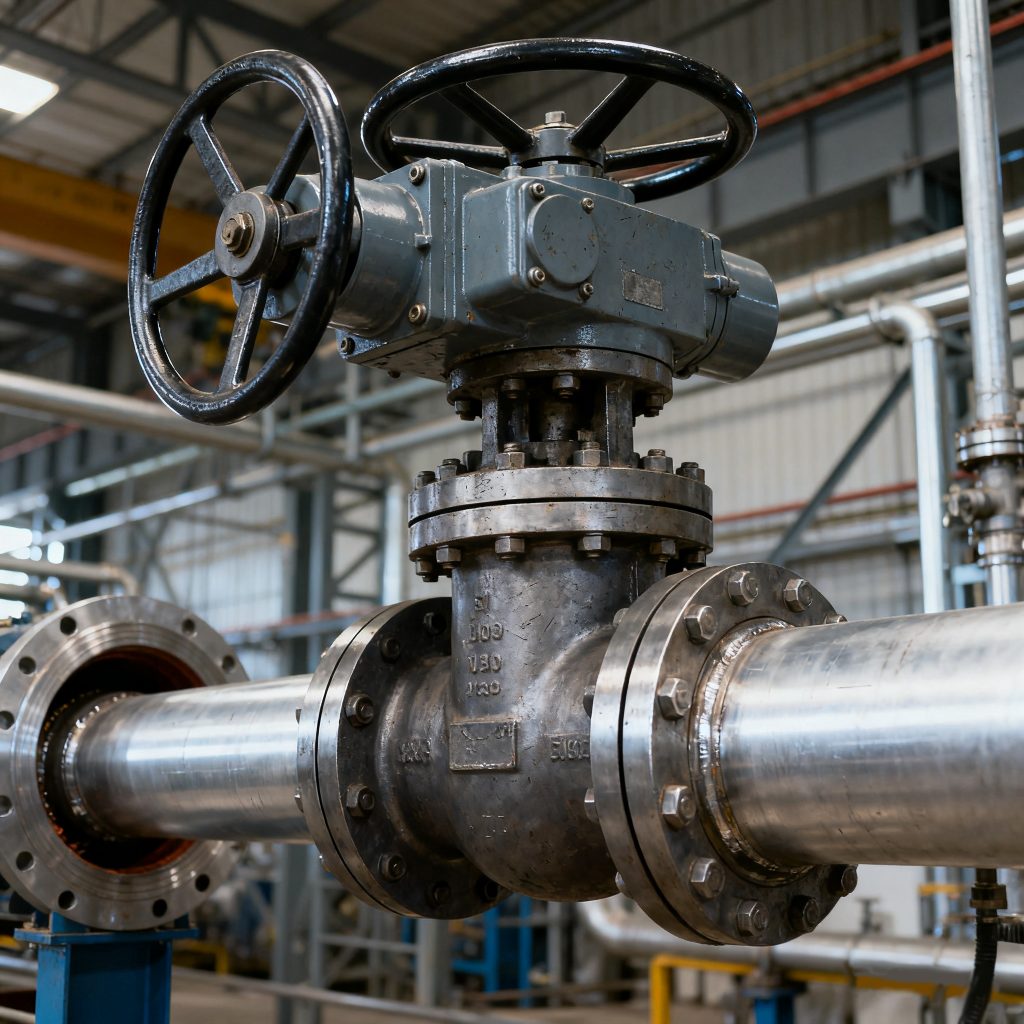

Industries widely use pneumatic butterfly valves because they use compressed air instead of complex electrical systems. Air pressure drives pneumatic actuators, rotating the valve disc to control flow. This principle depends on atmospheric pressure, using it as a stable reference under standard conditions.

Even at higher altitudes where pressure decreases compared to sea level pressure, these valves maintain reliable performance, making them ideal for large pipelines and high-pressure applications.

Key Advantages of Pneumatic Actuated Valves

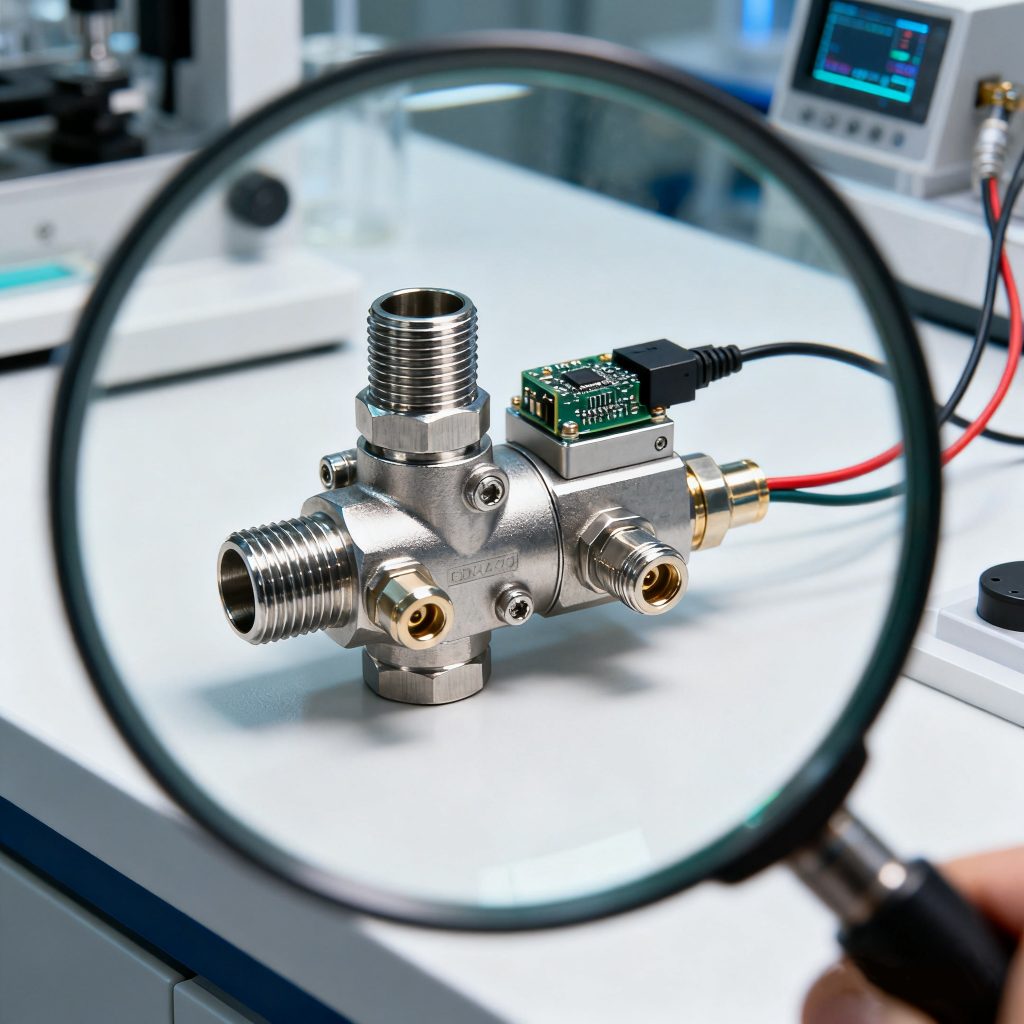

The pneumatic butterfly valve, one type of pneumatic actuated valve, offers several technical advantages that make it highly effective for industrial flow control. Compressed air moves the pneumatic actuators, rotating the valve disc to regulate or shut off flow with precision. The sender and receiver system quickly transmits air, enabling these valves to operate in real time—essential for processes that require frequent adjustments.

The design also supports durability under challenging conditions. Stainless steel components resist corrosion, while pneumatic systems remain largely unaffected by moisture, heat, or electrical interference—unlike electrically actuated alternatives. Furthermore, these valves maintain consistent performance even when atmospheric pressure varies, such as at higher altitudes where pressure decreases relative to sea level pressure. The combination of high pressure tolerance, fast response, and simple maintenance makes pneumatic butterfly valves a reliable choice for complex industrial systems.

Applications in Water and Wastewater Treatment Systems

In water and wastewater treatment systems, pneumatic butterfly valves play a critical role in controlling large volumes of fluid efficiently. The fast-acting pneumatic actuators allow valves to open or close almost instantly, ensuring precise flow control mechanisms even under fluctuating pressure conditions. Real-time valve adjustments allow operators to maintain precise control over different treatment stages and changing flow rates.

These valves are particularly useful for rapid isolation in distribution pipelines or emergency shut-off scenarios. Stainless steel construction resists corrosion from chemicals commonly present in treatment processes, while the simple design reduces maintenance downtime. Additionally, even when the column of air above the system varies with atmospheric pressure or barometric pressure changes, these valves maintain reliable operation. For more detailed technical references, industrial engineers often consult resources such as metoree.com

Applications in Chemical and Petrochemical Industries

In chemical and petrochemical industries, pneumatic butterfly valves are essential for handling aggressive or corrosive media. Their fast-acting pneumatic actuators enable precise control of flow control mechanisms in pipelines carrying acids, solvents, or other reactive substances. Real-time valve adjustments ensure that process flows remain stable even under fluctuating pressures, which is critical for both safety and product quality.

Stainless steel and other corrosion-resistant materials make these valves suitable for high pressure and chemically challenging environments. Pneumatic valves are particularly advantageous in areas where electrically actuated alternatives could be vulnerable to sparks or electrical interference. For engineers designing automated systems, integrating these valves with sender and receiver devices allows accurate monitoring of data flow and ensures reliable operation throughout complex chemical processes.

Applications in Power Generation and Energy Systems

In power generation and energy systems, pneumatic butterfly valves are widely used for controlling cooling water, steam, and auxiliary pipelines. Their pneumatic actuators respond quickly, allowing real-time valve adjustments that help maintain precise flow control mechanisms across different subsystems. This rapid response is particularly important in high-pressure environments, where minor delays could affect system efficiency or safety.

The valves’ stainless steel construction ensures durability against corrosion from water treatment chemicals and high-temperature fluids. Pneumatic systems are also less sensitive to electrical interference, making them reliable in environments where electrically actuated valves might be vulnerable. Additionally, pneumatic butterfly valves can accommodate variations in barometric pressure and atmospheric pressure, maintaining consistent operation even at higher altitudes. Engineers often integrate these valves into automated control systems to monitor and manage data flow efficiently in real time.

Applications in Food and Beverage Processing

In food and beverage processing, pneumatic butterfly valves are widely used for hygienic fluid handling. The fast-acting pneumatic actuators allow valves to open and close almost instantly, enabling real-time adjustments that maintain consistent flow control mechanisms across various production stages. This is especially important for precise dosing, mixing, and cleaning-in-place (CIP) operations.

Stainless steel construction ensures corrosion resistance and compliance with sanitary standards, while the simple design minimizes maintenance interruptions. Pneumatic valves also perform reliably under varying barometric pressure and atmospheric pressure conditions, maintaining smooth operation even in high-pressure cleaning or processing systems. Integrating these valves with automated control systems helps operators monitor data flow and adjust operations efficiently in real time.

Applications in HVAC and Industrial Utility Systems

Pneumatic butterfly valves are widely applied in HVAC and industrial utility systems to regulate air and water flow efficiently. Their pneumatic actuators provide fast, precise control, allowing real-time adjustments to maintain consistent flow control mechanisms across various sections of a facility. This ensures energy efficiency while preventing pressure fluctuations that could impact system performance.

Stainless steel and other corrosion-resistant materials allow the valves to withstand high pressure and exposure to different fluids. Pneumatic valves are particularly advantageous in environments where electrically actuated alternatives might face interference or reliability issues. Integration with automated monitoring systems enables operators to track data flow and adjust operations in real time, ensuring smooth and safe facility performance.

Integration with Automation and Control Systems

Pneumatic butterfly valves are easily integrated into modern automation and control systems, providing precise flow management in complex industrial processes. When connected with pneumatic actuators, positioners, and sender and receiver devices, these valves allow real-time monitoring and adjustment of data flow, ensuring the process remains within desired parameters. Flow control mechanisms can respond quickly to changes in pressure or demand, maintaining stability even under high pressure conditions.

Integration also supports electrically actuated hybrid systems, where pneumatic valves work alongside digital controllers to enhance process reliability. The use of stainless steel components ensures durability, while the combination of air pressure operation and automated monitoring reduces maintenance downtime. For engineers seeking detailed technical guidance, resources like datacenterworld.com offer practical insights on industrial automation integration.

How to Select Pneumatic Butterfly Valves for Different Industrial Applications

Selecting the right pneumatic butterfly valve requires careful consideration of several technical factors. The type of fluid, its temperature, and chemical properties influence material choice, with stainless steel often preferred for corrosive or high-pressure media. Valve size and pipeline pressure ratings must match system requirements to maintain efficient flow control mechanisms and prevent pressure decreases that could affect performance.

For precise process management, consider the actuator type and control system compatibility. Integrating pneumatic actuators with sender and receiver devices allows valves to adjust nearly in real time, while electrically actuated systems can be combined for hybrid applications. Understanding the standard atmosphere and variations in barometric pressure or sea level pressure is also important, especially in higher altitudes where flow characteristics may differ. Careful selection ensures reliability, safety, and minimal maintenance across diverse industrial environments.

Conclusion

Pneumatic butterfly valves offer a versatile and reliable solution for industrial flow control. Their fast-acting pneumatic actuators, stainless steel construction, and compatibility with automated systems ensure precise and stable flow control, even under varying pressures or at higher altitudes. Integration with modern monitoring enables real-time adjustments and efficient data flow, making these valves a preferred choice for engineers and industrial procurement professionals seeking durable, long-term solutions.

About Products

To explore our solutions and view detailed specifications, visit our Pneumatic Butterfly Valves product page for complete information and options.