Choosing the right pneumatic actuated ball valve is more than selecting hardware. It ensures safety, efficiency, and reliability across your industrial system. From oil and gas to food processing, compressed air actuators enable valves to open or close quickly and safely. Stainless steel or carbon steel quarter turn valves offer corrosion resistance and durability. Whether spring return or double acting, the right valve reduces downtime, lowers maintenance costs, and improves performance.

1.What Is a Pneumatic Ball Valve?

A pneumatic ball valve is an industrial valve that uses compressed air to drive a pneumatic actuator, which in turn rotates the ball inside the valve. This simple quarter turn movement allows the valve to fully open or close, controlling the flow of liquids or gases with ease.

Unlike manual valves, pneumatic actuated ball valves can operate automatically, making them ideal for systems that require speed, consistency, and safety. They are widely built with stainless steel, 316 stainless steel, or carbon steel, giving them strong corrosion resistant properties and the durability needed in harsh industrial environments.

2.Where Pneumatic Ball Valves Are Commonly Used

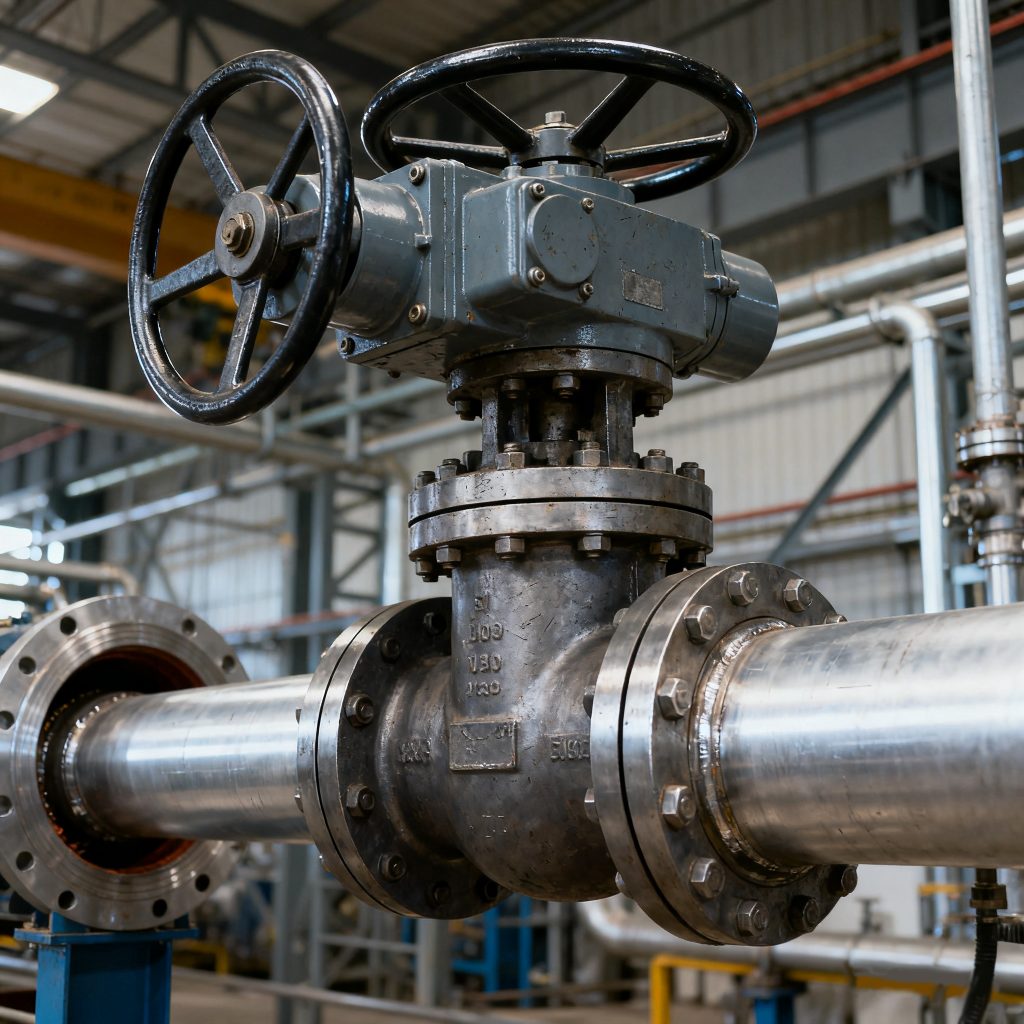

- Oil and Gas Industry – Used in explosion-proof environments where compressed air is safer than electricity. Provides quick quarter turn open or close action to protect high-pressure pipelines.

- Chemical Processing – Stainless steel and 316 stainless steel valves are chosen for corrosion resistant performance when handling aggressive or high-temperature fluids.

- Water Treatment Systems – Ensures reliable and low-cost operation by allowing pipelines to be opened or closed quickly.

- Food and Beverage Industry – Sanitary clamp designs meet hygiene standards while enabling fast installation and cleaning.

- Power Generation and Energy – Carbon steel valves handle high air pressure and demanding service where downtime is expensive.

- Compared to Butterfly Valves – Pneumatic ball valves provide tighter shut-off and more reliable sealing, making them a preferred choice for critical systems.

3.Main Advantages of Pneumatic Ball Valves

- Fast and Reliable Operation – Pneumatic actuated ball valves can open or close quickly with compressed air, reducing downtime and improving process efficiency. The quarter turn mechanism ensures smooth flow control.

- Explosion-Proof Safety – Unlike electric actuators, pneumatic actuators eliminate the risk of sparks, making them ideal for hazardous environments in oil, gas, and chemical industries.

- Durable and Corrosion Resistant – Valves made from stainless steel, 316 stainless steel, or carbon steel resist corrosion and wear, ensuring long service life even under high pressure and air pressure conditions.

- Low Maintenance Costs – With fewer moving parts than manual or electric valves, pneumatic ball valves require less frequent maintenance, reducing operational costs over time.

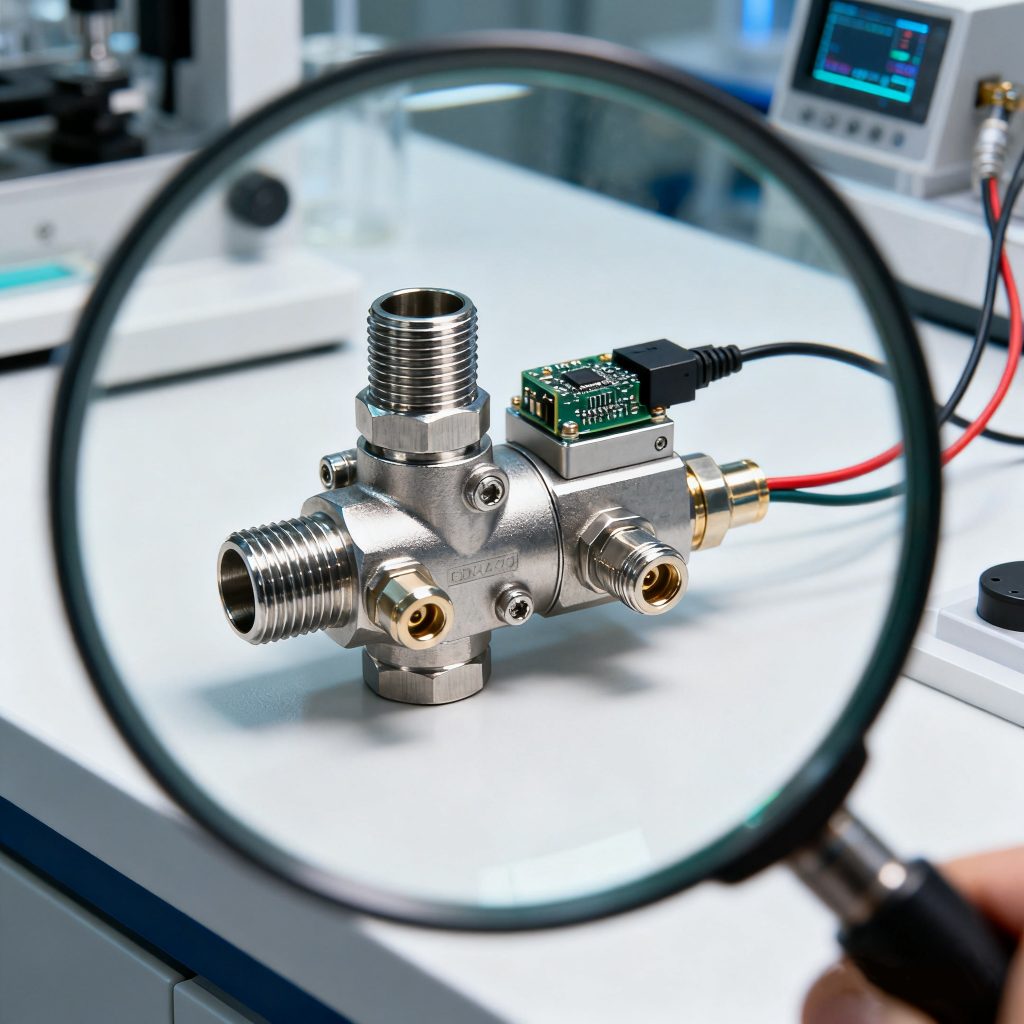

- Easy Integration with Automation – Pneumatic ball valves work well with positioners, sensors, and PLC systems, allowing for automated control in modern industrial setups.

- Versatility in Design – Available in spring return or double acting versions, these valves meet a wide range of operational needs and can be adapted for various industrial applications.

4.Key Factors in Selecting the Right Pneumatic Ball Valve

- Connection Type – Choose flanged, threaded, welded, or clamp connections that match your pipeline system for easy installation and reliable operation.

- Body Material – Stainless steel, 316 stainless steel, and carbon steel are popular choices due to their corrosion resistant properties and ability to handle high air pressure and harsh conditions.

- Seat and Seal Materials – PTFE, PEEK, and Viton should be selected based on the fluid, temperature, and pressure to ensure a tight shut-off and long service life.

- Operating Conditions – Consider temperature and pressure ranges to prevent premature wear or failure and ensure smooth operation.

- Actuator Type – Spring return or double acting actuators affect valve response, while compressed air supply and torque requirements determine performance under different loads.

- Automation and Control – Positioners, sensors, and PLC integration enhance process efficiency and allow seamless operation in automated systems.

Conclusion

Choosing the most suitable pneumatic actuated ball valve for your industry is a decision that affects safety, efficiency, and long-term performance.

- By carefully considering connection types, body materials such as stainless steel or carbon steel, seat and seal options, actuator type, operating conditions, and automation compatibility, you can select a valve that meets your system’s unique needs.

- Paying attention to additional factors like safety certifications, energy efficiency, maintenance practices, and custom features further ensures reliable operation.

- Avoiding common mistakes, such as ignoring operating conditions or choosing incorrect materials, will save time, reduce costs, and prevent system failures.

A well-selected pneumatic ball valve is not just a component—it is a key contributor to the smooth and safe operation of your industrial processes.

Future Outlook

The future of pneumatic actuated ball valves lies in automation, smart monitoring, and energy efficiency. With Industry 4.0 adoption, valves will use sensors and positioners for real-time feedback and remote control. Corrosion resistant materials and improved seat designs will extend life and reduce maintenance. Energy-efficient actuators and optimized compressed air use lower costs, while fire-safe, anti-static, and multi-port options meet complex industrial needs. Staying updated on these trends keeps systems safe, reliable, and future-ready.

About Products

Thank you for reading our article. To learn more about our solutions and products, check out our Pneumatic Ball Valves for detailed specifications and options.