Why Choose Electric Actuated Valve?

As an automated valve driven by an electric actuator, an electric actuated valve allows remote control and precise flow regulation. Compared to manual valves, it delivers:

- An order-of-magnitude higher precision

- Second-level response

- Plug-and-play 220 V power with zero manual effort

- Seamless local/remote control, predictive maintenance, and explosion-proof design for a safer, more stable, and more economical system.

Why Choose Electric Actuated Valve?

As an automated valve driven by an electric actuator, an electric actuated valve allows remote control and precise flow regulation. Compared to manual valves, it delivers:

- An order-of-magnitude higher precision

- Second-level response

- Plug-and-play 220 V power with zero manual effort

- Seamless local/remote control, predictive maintenance, and explosion-proof design for a safer, more stable, and more economical system.

Electric Actuated Valve Series

Electric Ball Valves

Electric ball valves ensure full-port, bubble-tight control with precise remote shut-off and modulation, delivering more efficient and worry-free flow control. We offer multiple sizes and materials tomeet your specific needs.

Electric Butterfly Valves

Electric butterfly valves feature a compact design and flexible operation, enabling remote automation with efficient flow regulation and reliable sealing. With a lower cost and simple structure, they are suitable for many systems.

Electric Gate Valves

Electric gate valves automate opening and closing, replacing heavy traditional valves with ease. With low resistance and secure sealing, they ensure safe operation even under high temperature and pressure.

Electric Ball Valves

Electric ball valves ensure full-port, bubble-tight control with precise remote shut-off and modulation, delivering more efficient and worry-free flow control. We offer multiple sizes and materials tomeet your specific needs.

Electric Butterfly Valves

Electric butterfly valves feature a compact design and flexible operation, enabling remote automation with efficient flow regulation and reliable sealing. With a lower cost and simple structure, they are suitable for many systems.

Electric Gate Valves

Electric gate valves automate opening and closing, replacing heavy traditional valves with ease. With low resistance and secure sealing, they ensure safe operation even under high temperature and pressure.

Electric Knife Gate Valve

Electric knife gate valves automate the shut-off of thick fluids, slurries, and media containing solids. The sharp gate cuts through tough flow easily, while the compact electric design makes operation simple and safe. Suitable for mining.

Electric Globe Valves

Electric globe valves allow easy, single-step flow regulation and reliable shut-off, improving control efficiency and supporting automated operation in industrial systems.

Electric Knife Gate Valve

Electric knife gate valves automate the shut-off of thick fluids, slurries, and media containing solids. The sharp gate cuts through tough flow easily, while the compact electric design makes operation simple and safe. Suitable for mining.

Electric Globe Valves

Electric globe valves allow easy, single-step flow regulation and reliable shut-off, improving control efficiency and supporting automated operation in industrial systems.

Related Actuators

Modulating Electric Actuators

The modulating electric actuator enables continuous valve position control for precise flow regulation. It supports 4–20mA, 0–10V, and 0–5V analog input signals, with multiple torque options, a standard manual override, and an optional local control panel.

Explosion-Proof Electric Actuators

CNEX-certified explosion-proof electric actuator with handwheel, available in on-off or regulation type for heavy-duty industrial applications, supporting various valves and analog signals, with multiple torque options and optional local control panel.

Multiturn Electric Actuators

Multiturn electric actuators are available in on-off type and regulation type, providing both basic valve control and precise valve positioning. The regulation type enables continuous modulation for flow, pressure, and temperature control, making it suitable for a wide range of industries and applications.

Modulating Electric Actuators

The modulating electric actuator enables continuous valve position control for precise flow regulation. It supports 4–20mA, 0–10V, and 0–5V analog input signals, with multiple torque options, a standard manual override, and an optional local control panel.

Explosion-Proof Electric Actuators

CNEX-certified explosion-proof electric actuator with handwheel, available in on-off or regulation type for heavy-duty industrial applications, supporting various valves and analog signals, with multiple torque options and optional local control panel.

Multiturn Electric Actuators

Multiturn electric actuators are available in on-off type and regulation type, providing both basic valve control and precise valve positioning. The regulation type enables continuous modulation for flow, pressure, and temperature control, making it suitable for a wide range of industries and applications.

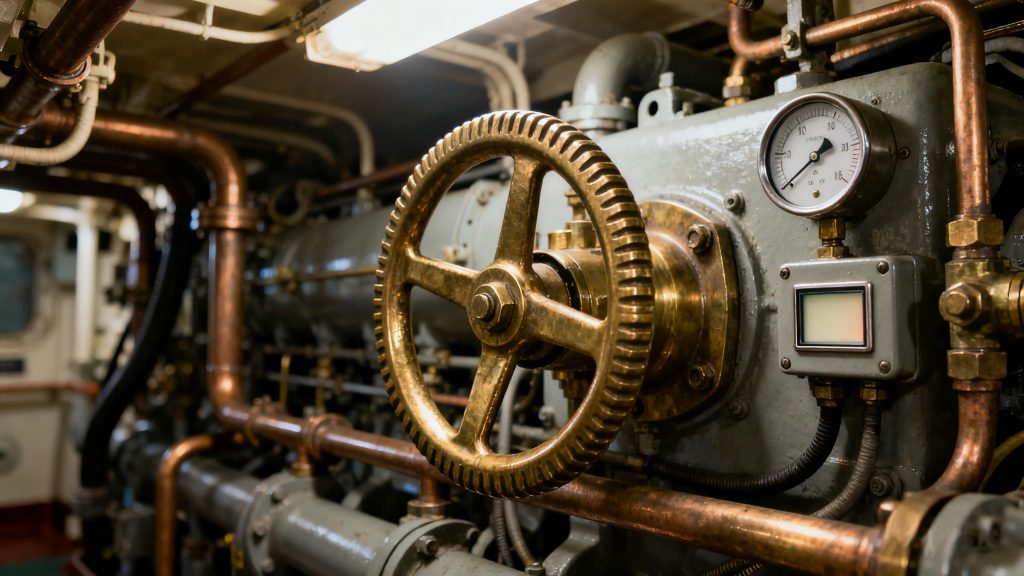

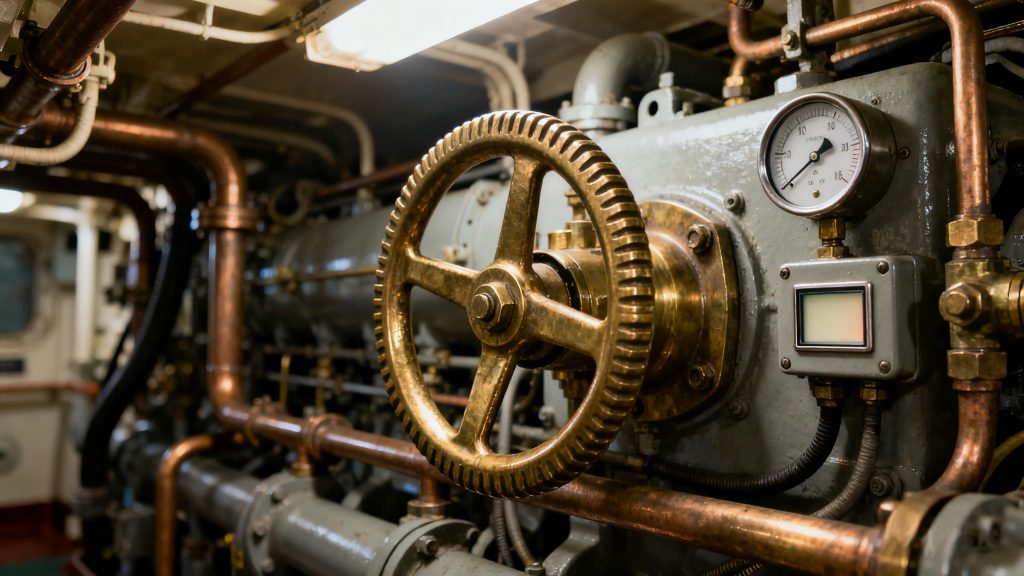

Electric Actuated Valves In Industries:

Water & Wastewater Treatment

- Precise control – Regulate flow and pressure with accuracy.

Reliable isolation – Ensure safe system shutdowns and maintenance.

Seamless automation – Integrate with SCADA for remote operation.

Process efficiency – Improve performance and maintain water quality.

Oil & Gas

- Accurate flow control – Manage crude, gas, and refined products with precision.

Enhanced safety – Provide reliable shut-off in critical operations.

Remote automation – Integrate with control systems for real-time monitoring.

Operational efficiency – Reduce downtime and support continuous production.

Water & Wastewater Treatment

- Precise control – Regulate flow and pressure with accuracy.

Reliable isolation – Ensure safe system shutdowns and maintenance.

Seamless automation – Integrate with SCADA for remote operation.

Process efficiency – Improve performance and maintain water quality.

Oil & Gas

- Accurate flow control – Manage crude, gas, and refined products with precision.

Enhanced safety – Provide reliable shut-off in critical operations.

Remote automation – Integrate with control systems for real-time monitoring.

Operational efficiency – Reduce downtime and support continuous production.

Power & Energy

- Precise steam and water control – Ensure stable flow in boilers, turbines, and cooling systems.

Enhanced safety – Provide reliable shut-off in high-pressure, high-temperature environments.

Automation integration – Support plant-wide monitoring and remote operation.

Efficiency and reliability – Improve energy efficiency and reduce unplanned downtime.

General Industry

- Versatile flow control – Handle water, chemicals, air, and other industrial media.

Reliable isolation – Provide safe shutdown for maintenance and process changes.

Automation-ready – Easily integrate into modern industrial control systems.

Process efficiency – Enhance productivity and ensure consistent operations.

Power & Energy

- Precise steam and water control – Ensure stable flow in boilers, turbines, and cooling systems.

Enhanced safety – Provide reliable shut-off in high-pressure, high-temperature environments.

Automation integration – Support plant-wide monitoring and remote operation.

Efficiency and reliability – Improve energy efficiency and reduce unplanned downtime.

General Industry

- Versatile flow control – Handle water, chemicals, air, and other industrial media.

Reliable isolation – Provide safe shutdown for maintenance and process changes.

Automation-ready – Easily integrate into modern industrial control systems.

Process efficiency – Enhance productivity and ensure consistent operations.

Which Valve Should You Choose for Your System?

wanvalve provides one-stop valve solutions to simplify valve selection and procurement. As a trusted valve supplier, we offer the most cost-effective valves at the best price, ensuring the right choice for diverse applications and delivering maximum value with peace of mind.

Which Valve Should You Choose for Your System?

wanvalve provides one-stop valve solutions to simplify valve selection and procurement. As a trusted valve supplier, we offer the most cost-effective valves at the best price, ensuring the right choice for diverse applications and delivering maximum value with peace of mind.

Relational Guide

Do electric actuated valves require an external power supply?

Yes. Common power supply options are AC220V, AC380V, or DC24V.

Can electric actuated valves be used in explosive environments?

Yes, but only with explosion-proof actuators that meet safety standards.

Can electric actuated valves be operated manually?

Yes. Most electric actuators come with a manual handwheel for operation during power loss or failure.

What materials and types of electric valves are available? What options are offered for electric actuators?

Electric valves come in a variety of materials, including stainless steel, brass, UPVC, cast iron, cast steel, and PTFE-lined options (PTFE is mainly used for high-temperature applications). There are multiple valve types to meet different industry needs, with the main products displayed on this page. Electric actuators are available in on/off, regulating, and intelligent control types, and can be customized with options such as explosion-proof or waterproof protection.

What is the lifespan and maintenance requirement of electric actuated valves?

They usually last 5–10 years. Regular maintenance includes electrical inspections, valve cleaning, lubrication of moving parts, and signal calibration.

How to choose the right electric actuated valve?

Selection depends on medium properties, valve size, control type, power supply, and application environment (e.g., explosion-proof requirements). If you have any questions during the process, our engineers will help you analyze the options and select the most suitable valve for your needs.

Do electric actuated valves require an external power supply?

Yes. Common power supply options are AC220V, AC380V, or DC24V.

Can electric actuated valves be used in explosive environments?

Yes, but only with explosion-proof actuators that meet safety standards.

Can electric actuated valves be operated manually?

Yes. Most electric actuators come with a manual handwheel for operation during power loss or failure.

What materials and types of electric valves are available? What options are offered for electric actuators?

Electric valves come in a variety of materials, including stainless steel, brass, UPVC, cast iron, cast steel, and PTFE-lined options (PTFE is mainly used for high-temperature applications). There are multiple valve types to meet different industry needs, with the main products displayed on this page. Electric actuators are available in on/off, regulating, and intelligent control types, and can be customized with options such as explosion-proof or waterproof protection.

What is the lifespan and maintenance requirement of electric actuated valves?

They usually last 5–10 years. Regular maintenance includes electrical inspections, valve cleaning, lubrication of moving parts, and signal calibration.

How to choose the right electric actuated valve?

Selection depends on medium properties, valve size, control type, power supply, and application environment (e.g., explosion-proof requirements). If you have any questions during the process, our engineers will help you analyze the options and select the most suitable valve for your needs.